Aqueous capacitor battery and preparation method thereof

A capacitor battery and water system technology, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors to achieve good rate performance and cycle performance, novel design and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] Correspondingly, as image 3 as shown, image 3 A schematic diagram of the manufacturing process of the electrode of the aqueous capacitor battery according to the preferred embodiment of the present invention is shown. The present invention also proposes a preparation method for the above-mentioned water system capacitor battery, comprising the following steps:

[0043] Step S1, configuring a quinone molecular solution, and configuring a hydroquinone molecular solution;

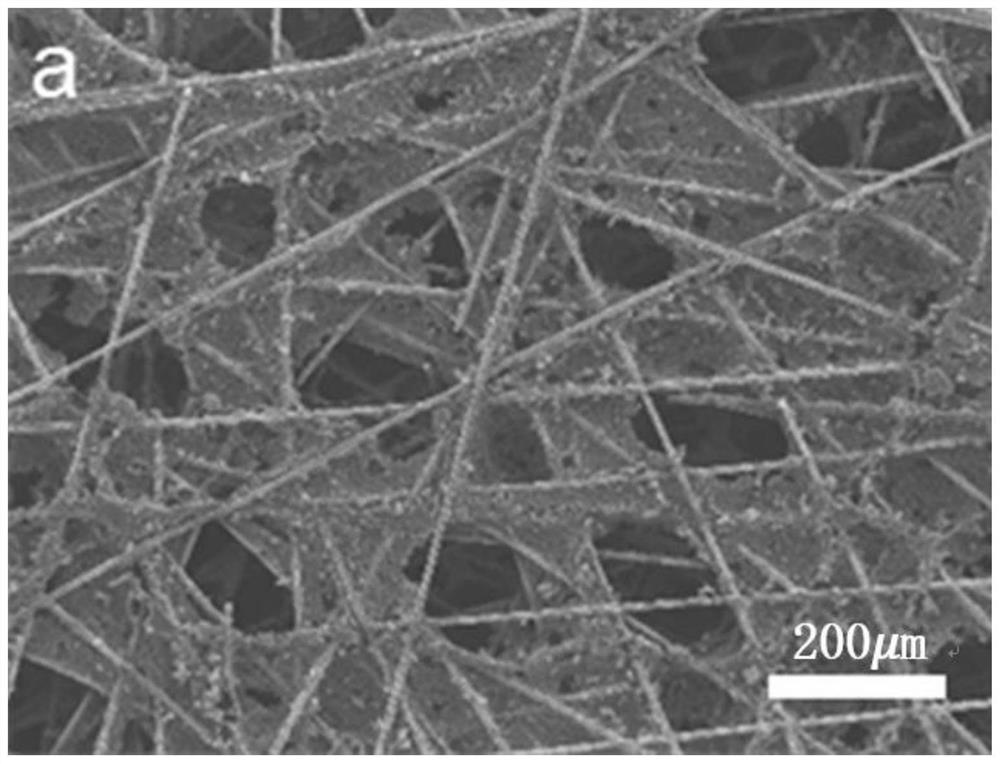

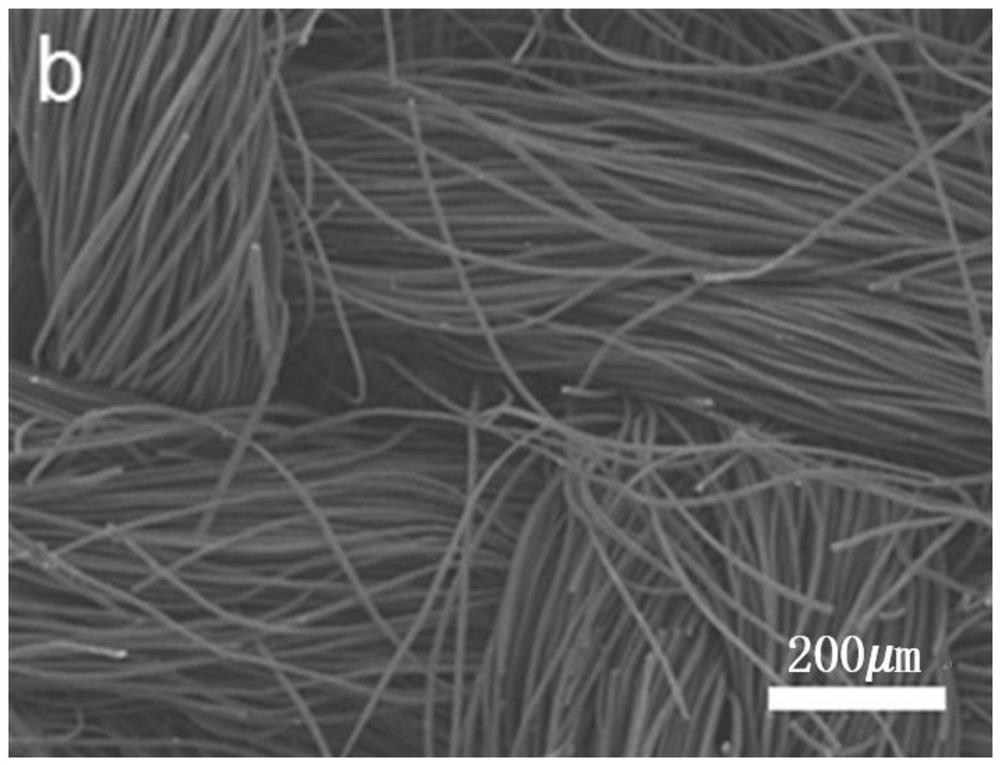

[0044] Step S2, providing a first carbon substrate, and immersing the first carbon substrate in a solution of quinone molecules, taking it out, and cleaning it with sulfuric acid to obtain a negative electrode;

[0045] providing a second carbon substrate, and immersing the second carbon substrate in a diphenol molecular solution, taking it out, and cleaning it with sulfuric acid to obtain a positive electrode;

[0046] The standard electrode potential of quinone molecules is higher than that of qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com