An automatic feeder cable production assembly device

A combination device and feeder cable technology, which is applied in the direction of cable installation device, cable installation, dismantling/armored cable equipment, etc., can solve problems such as affecting the quality of the feeder cable head, damage to the feeder copper tube, etc., to reduce the economic cost Loss, increase production efficiency, reduce impact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

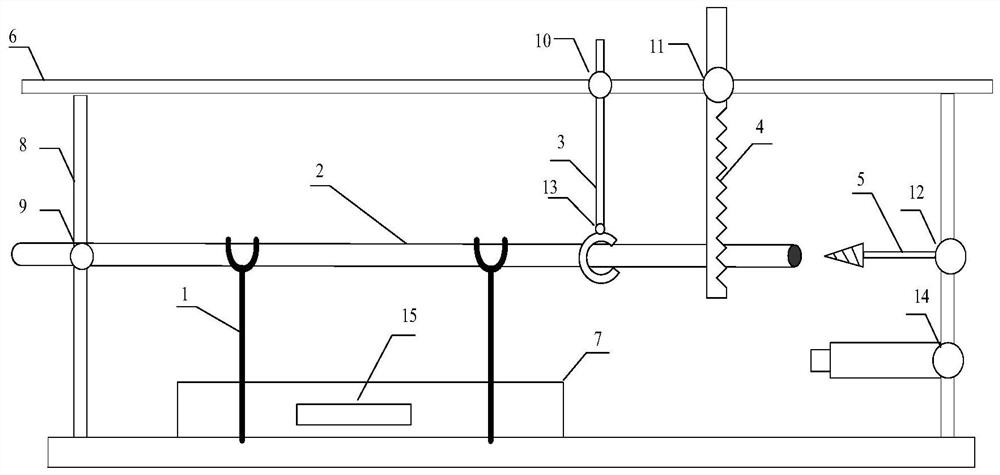

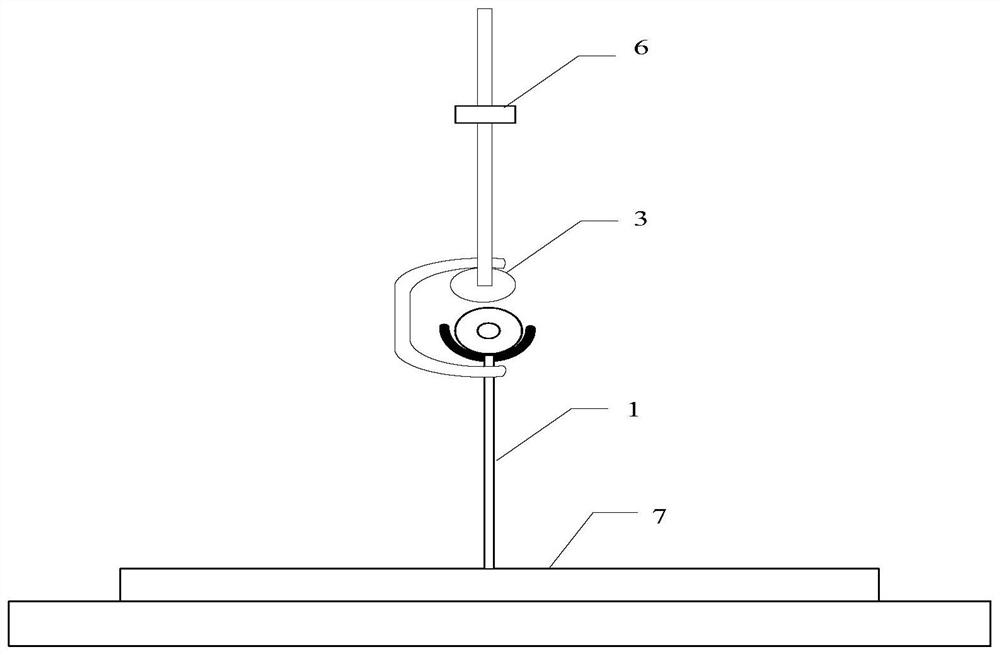

[0025] The present embodiment provides a kind of automatic feeder head making combination device, such as Figure 1-2 As shown, it includes feeder cable fixing frame 1, rotary cutter 3, sawtooth cutter 4, rotary reamer 5, scale platform 6, fixed platform 7, bracket 8, feeder telescopic control motor 9, rotary cutter Telescopic control motor 10, sawtooth cutter control motor 11, rotary reaming control motor 12, feeder cable head installation fastening motor 14, integrated power supply system 15 and control circuit; the feeder cable fixing frame 1 is arranged on the fixed platform 7, used to fix the feeder cable 2; the scale platform 6 is set above the feeder cable fixing frame 1 through a bracket 8, and its surface is provided with a scale along the length direction; the feeder cable telescopic control motor 9 is fixed on On the bracket 8, it is used to connect the feeder cable 2 and drive it to move back and forth; the rotary cutter 3 is used to cut the outer skin of the feede...

Embodiment 2

[0031] This embodiment provides a method for making a combined device using the automatic cable feeder described in Embodiment 1, including the following steps:

[0032] S1. Fix the feeder cable on the feeder cable fixing frame to ensure that the feeder cable does not move or deviate, and connect the feeder cable with the feeder cable telescopic control motor;

[0033] S2. Move the rotary cutter telescopic control motor together with the rotary cutter, the sawtooth cutter control motor and the sawtooth cutter along the length direction of the scale platform to the set position of the feeder cable; The head is installed to fasten the motor connection;

[0034] S3. The control circuit controls the telescopic control motor of the rotary cutter to drive the rotary cutter to move down to the position of the feeder cable, and the rotary cutter is at the corresponding position of the feeder cable along the central position of the trough of the feeder cable corrugation Ring cutting a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com