Side leakage prevention structure for diaper and making method of side leakage prevention structure

A trousers-proof and two-division technology, applied in the field of diapers, can solve problems such as breakage, side leakage of excrement, affecting water repellency effect, etc., and achieve the effects of not being easily damaged, ensuring air permeability, and high physical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

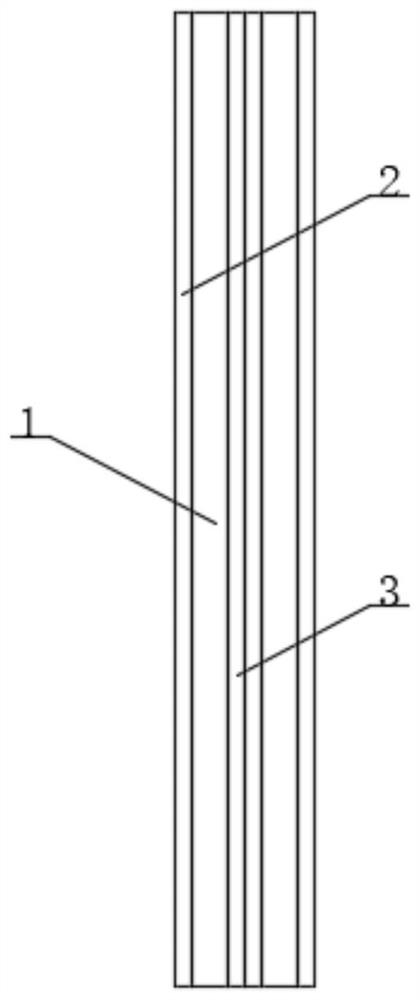

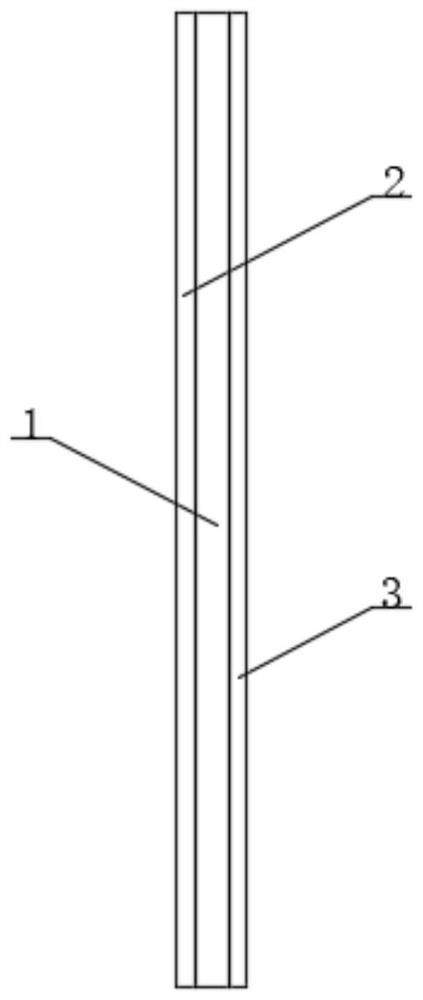

[0022] see Figure 1-4 , the present invention provides a technical solution: a diaper anti-side leakage structure, including a non-woven fabric 1, a PE film 2 and an elastic layer 3, the non-woven fabric 1 is composed of a water-repellent SS non-woven fabric, and the The non-woven fabric 1 is a composite structure, and the non-woven fabric 1 is formed by pressing and compounding three layers of non-woven fabric raw materials. The processing size of the non-woven fabric 1 is a width of 280 mm. The non-woven fabric 1. Ventilation holes are evenly opened on the surface, and a PE film 2 is fused and pasted on one side of the non-woven fabric 1. The PE film 2 is specifically a breathable PE film. The processing size of the PE film 2 is a width of 120 mm, the other side of the non-woven fabric 1 is fused and pasted with an elastic layer 3, the elastic layer 3 is specifically composed of elastic, the elastic layer 3 is a mirror structure, and the thickness of the PE film 2 is the sa...

Embodiment 2

[0024] see Figure 1-4 , the present invention provides a technical solution: a diaper anti-side leakage structure, including a non-woven fabric 1, a PE film 2 and an elastic layer 3, the non-woven fabric 1 is composed of SMS non-woven fabric, the non-woven fabric The cloth 1 is a composite structure, and the non-woven fabric 1 is formed by pressing and compounding three layers of non-woven fabric raw materials. The processing size of the non-woven fabric 1 is a width of 280 mm. The surface of the non-woven fabric 1 is Ventilation holes are evenly opened, and a PE film 2 is fused and pasted on one side of the non-woven fabric 1. The PE film 2 is specifically a breathable PE film. The processing size of the PE film 2 is 120 mm in width. The other side of the non-woven fabric 1 is fused and pasted with an elastic layer 3, the elastic layer 3 is specifically composed of elastic, the elastic layer 3 is a mirror structure, and the thickness of the PE film 2 is the same as that of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com