Mixed material screening device for waste battery treatment

A technology for used batteries and screening devices, which can be used in filter screens, magnetic separation, solid separation, etc., and can solve problems such as difficult separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

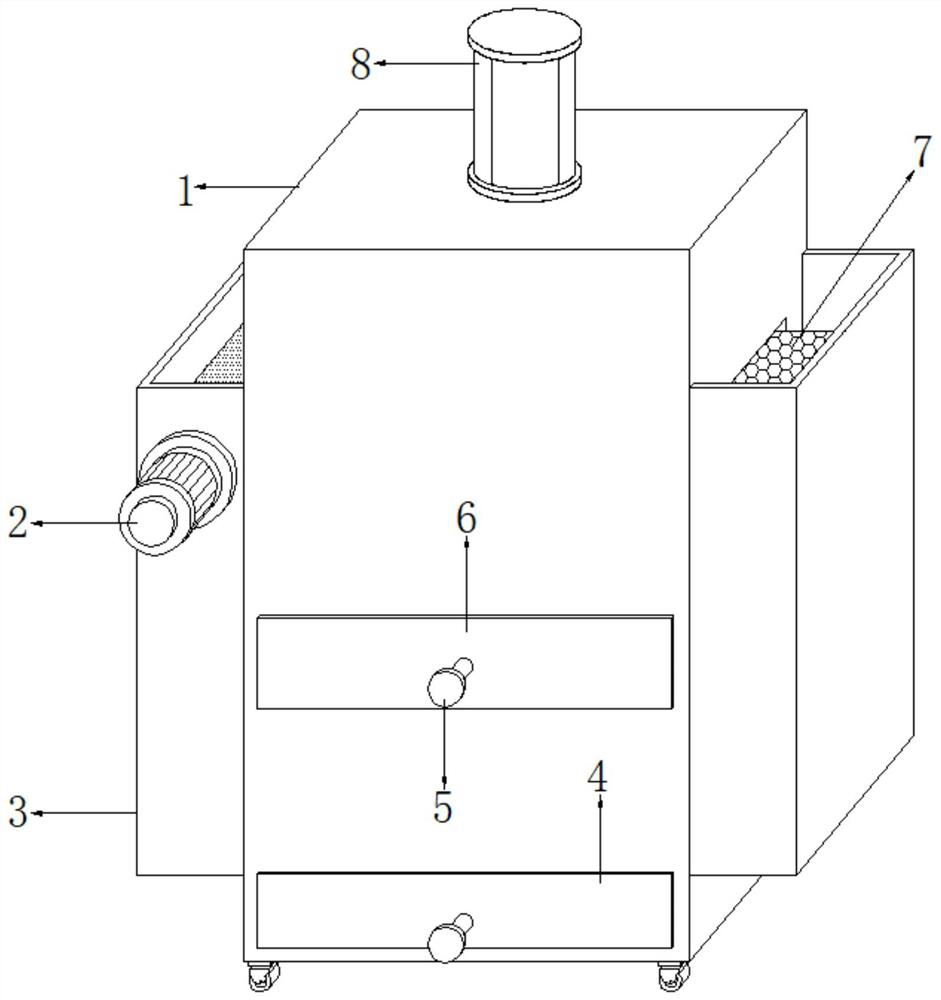

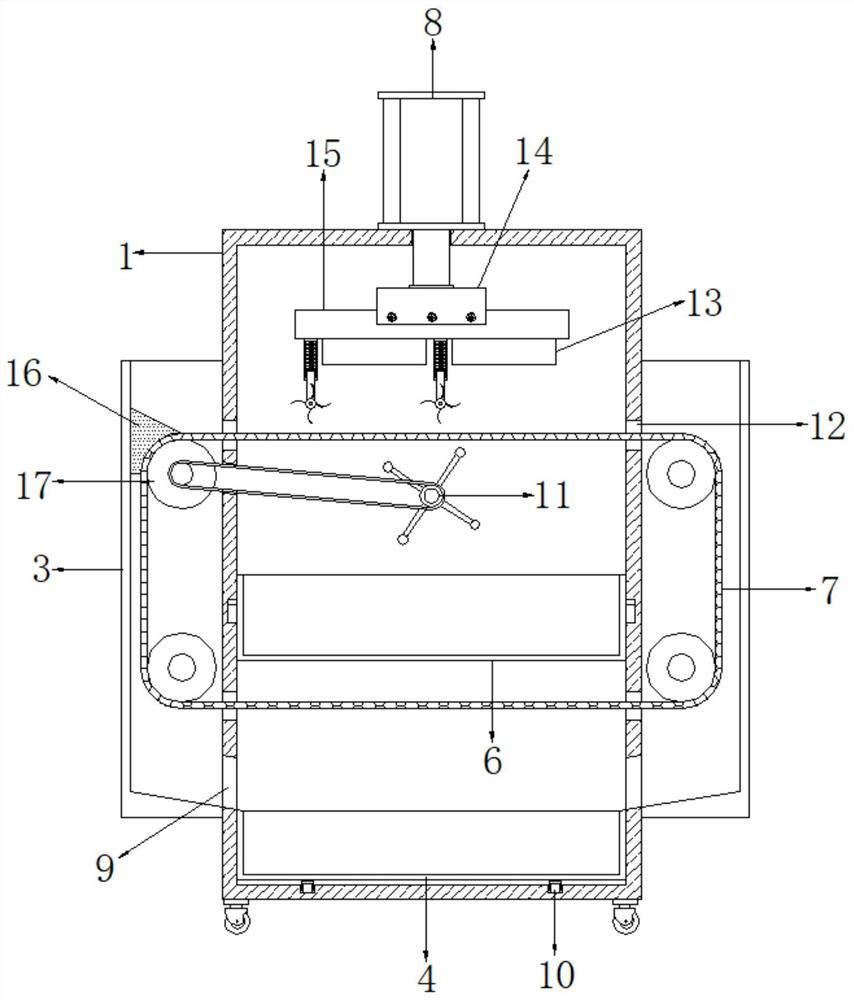

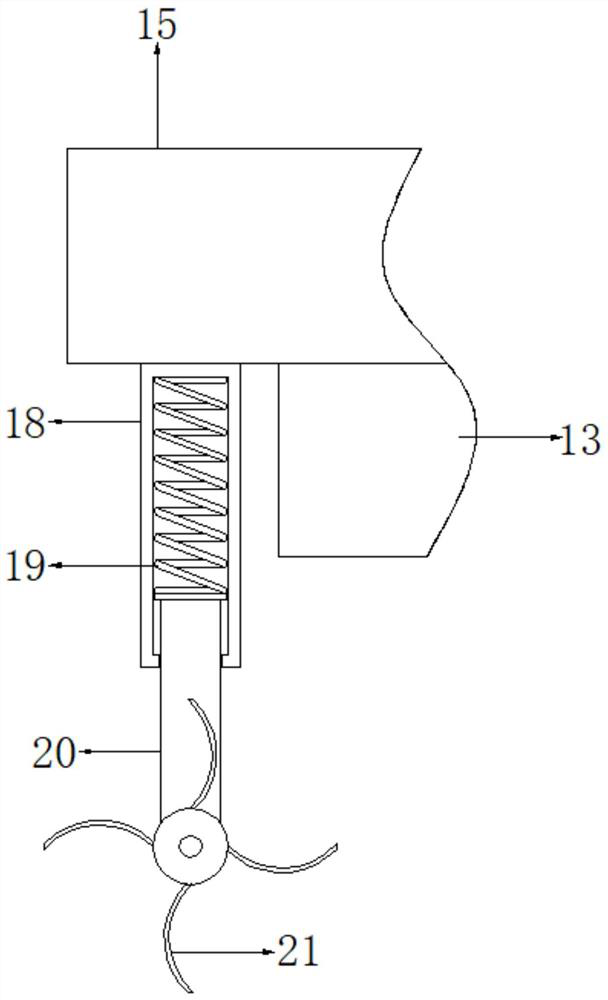

[0029] refer to Figure 1-4 , a mixing and screening device for waste battery treatment, comprising a screening box 1, the outer walls on both sides of the screening box 1 are connected with side frames 3 by bolts, and the top and bottom of the inner walls on both sides of the side frame 3 Both are connected with rotating rollers 17 through bearings, the top and bottom of both sides of the screening box 1 are provided with installation through grooves 12, and the outer wall of the rotating rollers 17 is connected with a transmission mesh belt 7 passing through the installation through grooves 12. The outer wall of one side of the frame 3 is connected with a motor 2 by bolts, and the output shaft of the motor 2 is connected with one end of the rotating roller 17 by bolts, and the middle position of the top of the screening box 1 is connected with an electric push rod 8 by bolts, and the electric push rod 8 is connected by bolts. The bottom end of the piston rod of the push rod ...

Embodiment 2

[0038] refer to Figure 5 , a mixing and screening device for waste battery treatment. Compared with Embodiment 1, this embodiment replaces the transmission shaft 11, the transmission belt 22, the connecting rod 23 and the impact ball 24 with a vibration motor 25, and the number of vibration motors 25 There are two vibrating motors 25 connected to the outer walls on both sides of the screening box 1 by bolts, one side of the vibrating motor 25 is connected with a vibrating block 26 by bolts, one side of the vibrating block 26 is connected to one side of the transmission mesh belt 7 The inner walls are in contact.

[0039] Working principle: When in use, the user uses the vibrating motor 25 and the vibrating block 26 to vibrate both sides of the transmission mesh belt 7, so as to vibrate the mixed material on the transmission mesh belt 7, so that the screening effect is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com