Telescopic Drum Type Gorgon Grain Grading Device

A grading device and drum-type technology, which is applied in the direction of solid separation, chemical instruments and methods, and grids, can solve the problems of limited size range of Gorgon seed sorting, affecting the mechanized processing of Gorgon seed, increasing the intensity of grading work, etc., to achieve The effects of improving sorting quality and sorting efficiency, improving flexibility and adaptability, and reducing labor and labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and provides detailed implementation modes and specific operation processes, but the protection scope of the present invention is not limited to the following implementations example.

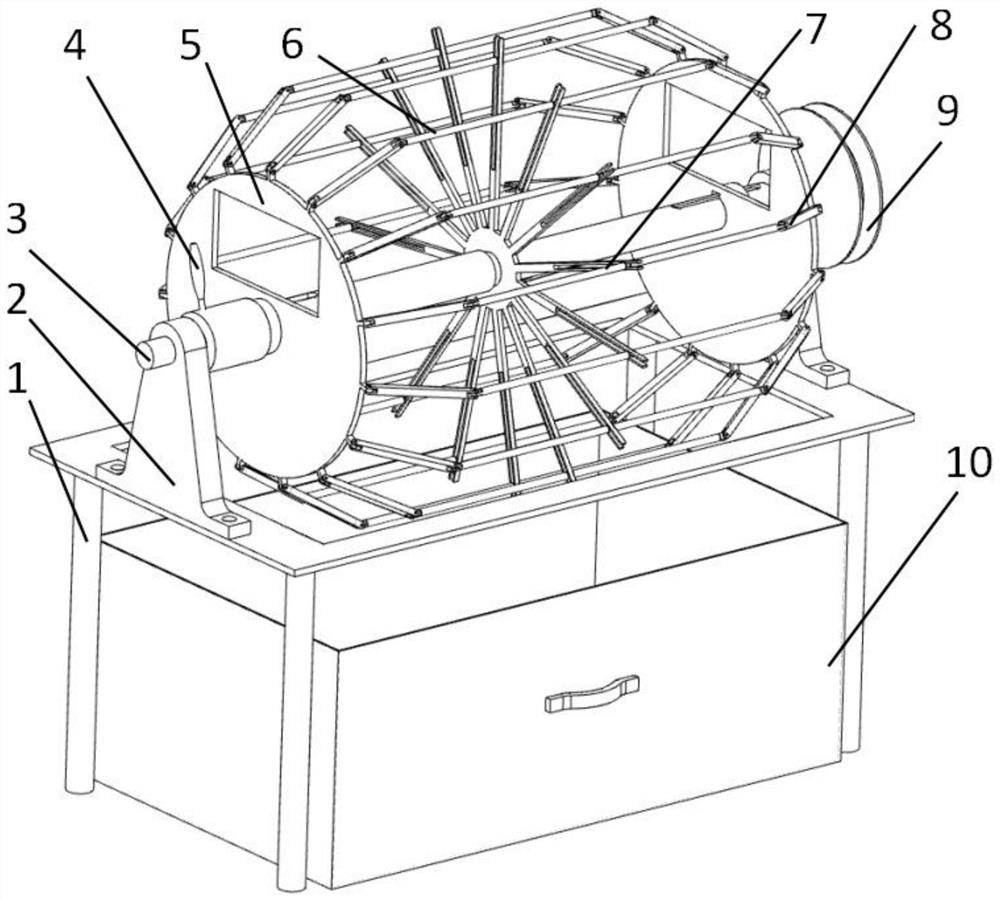

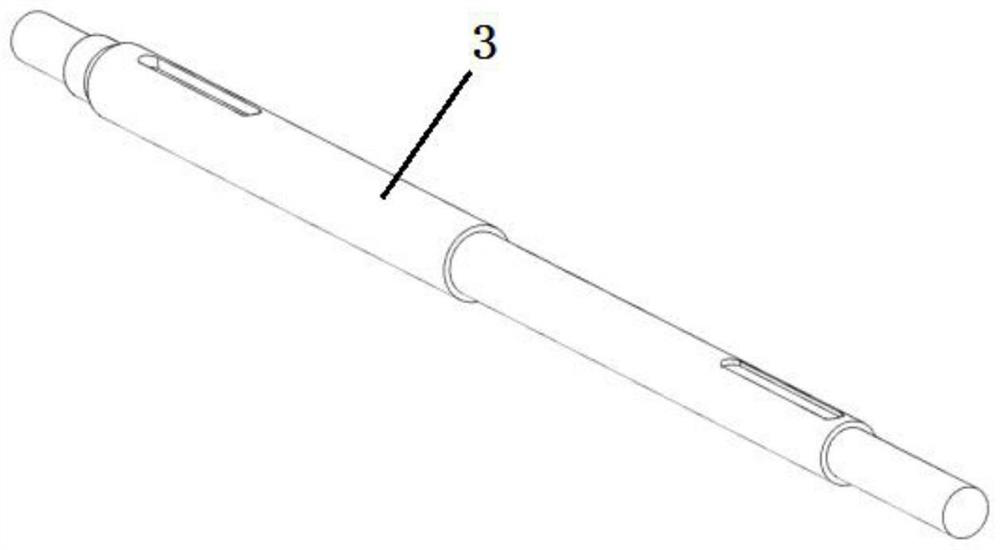

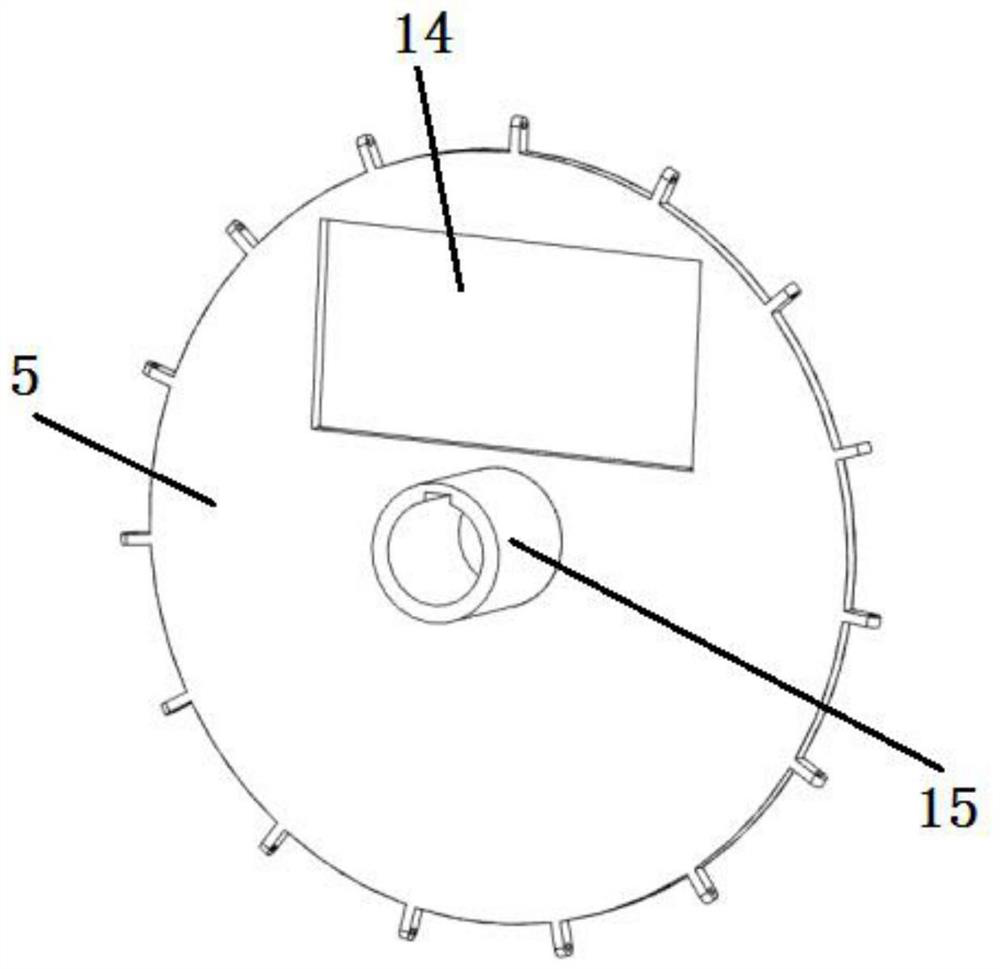

[0024] see Figure 1 to Figure 7 , the present embodiment discloses a telescopic drum type gorgon grain classification device, comprising an installation table 1, the installation table 1 is provided with two left and right installation brackets 2, the transmission shaft 3 extends in the left and right direction, and the left and right ends of the transmission shaft 3 Rotate and install on two mounting brackets 2 respectively.

[0025] The transmission shaft 3 is provided with a grading drum, the installation platform 1 is provided with a through groove under the grading drum, and a material box 10 is arranged under the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com