Screening device for fertilizer production and screening method thereof

A screening device and fertilizer technology, applied in chemical instruments and methods, screening, solid separation, etc., can solve the problems of poor screening effect and low screening efficiency, achieve good screening effect and improve screening efficiency , The effect of convenient speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

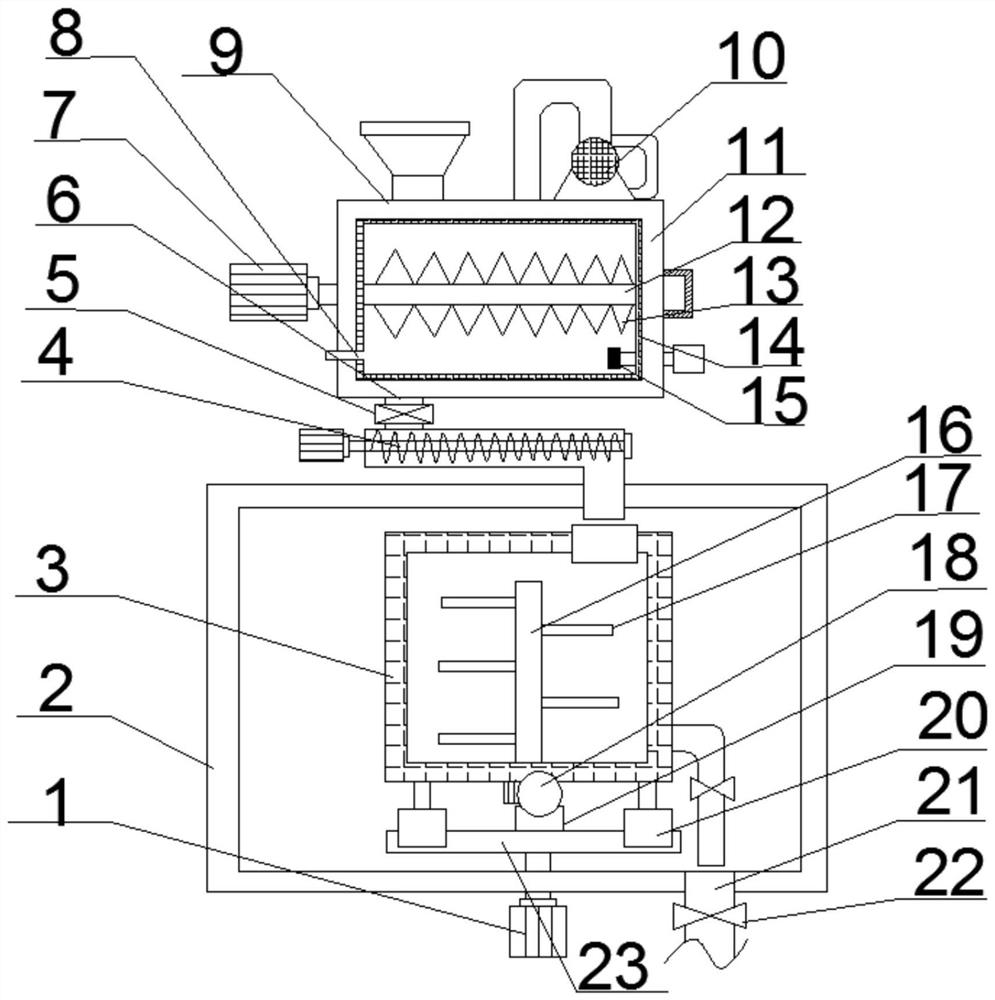

[0033] refer to figure 1 A kind of screening device for producing fertilizer provided by the present invention comprises a screening chamber 2, a screen cylinder 3 is connected in the screening chamber 2, a drive structure for driving the rotation of the screen cylinder 3 is connected to the bottom of the screen cylinder 3, and the screen The top of the sub-bin 2 is connected with a drying structure, the drying structure includes a drying bin 9 connected to the top of the screening bin 2 through a feeding pipe 6, a solenoid valve 5 is connected to the feeding pipe 6, and the bin wall of the drying bin 9 has an inner wall and an outer wall A heating chamber 11 is formed, and the heating chamber 11 is connected with a heat pump 10. The heating chamber 11 is provided with a plurality of hot air ports 14, and the drying chamber 9 is provided with an exhaust port 8. The drying chamber 9 is connected with a stirring structure, and the screen cylinder 3 A discharge pipe 21 is connect...

Embodiment 2

[0036] Based on Example 1, with reference to figure 1 , the driving structure of this embodiment includes a first motor 1 connected to the bottom of the screening chamber 2, a support plate 23 is connected to the output shaft of the first motor 1, and the screen cylinder 3 is connected to the support plate 23.

[0037] When it is necessary to drive the entire screen cylinder 3 to rotate, the output shaft of the first motor 1 can be rotated by starting the first motor 1, so that the support plate 23 connected to the output shaft of the first motor 1 is rotated, and then the connection When the screen cylinder 3 on the support plate 23 rotates, the effect of rotation and vibration of the screen cylinder 3 can be realized, and the efficiency of screening can be improved.

Embodiment 3

[0039] Based on Example 2, refer to figure 1 , A vibrating structure is connected between the screen cylinder 3 and the support plate 23 in this embodiment.

[0040] In the present application, a vibrating structure is connected between the screen cylinder 3 and the support plate 23, so that the vibration effect of the vibration structure can make the vibration frequency of the screen cylinder 3 higher and the vibration amplitude larger, further improving the screening efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com