Patents

Literature

34results about How to "Easy to filter out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for organic acid hydrolytic producing amino-acid

InactiveCN1757633ASolve the separation problemReduce solubilityOrganic compound preparationAmino-carboxyl compound preparationFiltrationAmino Acid Injection

The invention relates to a method of amino-acid with hydrolysis of organic acid or mixed acid (mixing an organic acid and hydrogen chloride with different proportion based on various salt-containing of different products), including the following steps: (1) pre-treatment of raw material; (2) hydrolysis, neutralization; (3) produced amino-acid solution after blending and filtration; (4) going to market after sterilizing, filling in tins, labelling, inspecting and packing. More steps needed for producing amino-acid powder: after adding additives and fillings needed, dissolving, stirring, appropriate concentrating and drying in drying machine, the amino-acid powder is produced, then going to market after packing, labelling, inspecting and packing in boxes. Based on different kind of raw material hydrolysis animal albumen (HAP) and hydrolysis plant albumen (HVP) and various kind of amino-acid preparation may be made with amino-acid. The amino-acid met pharmaceutical grade may be provided as raw material of amino-acid injection solution.

Owner:陈贵卿

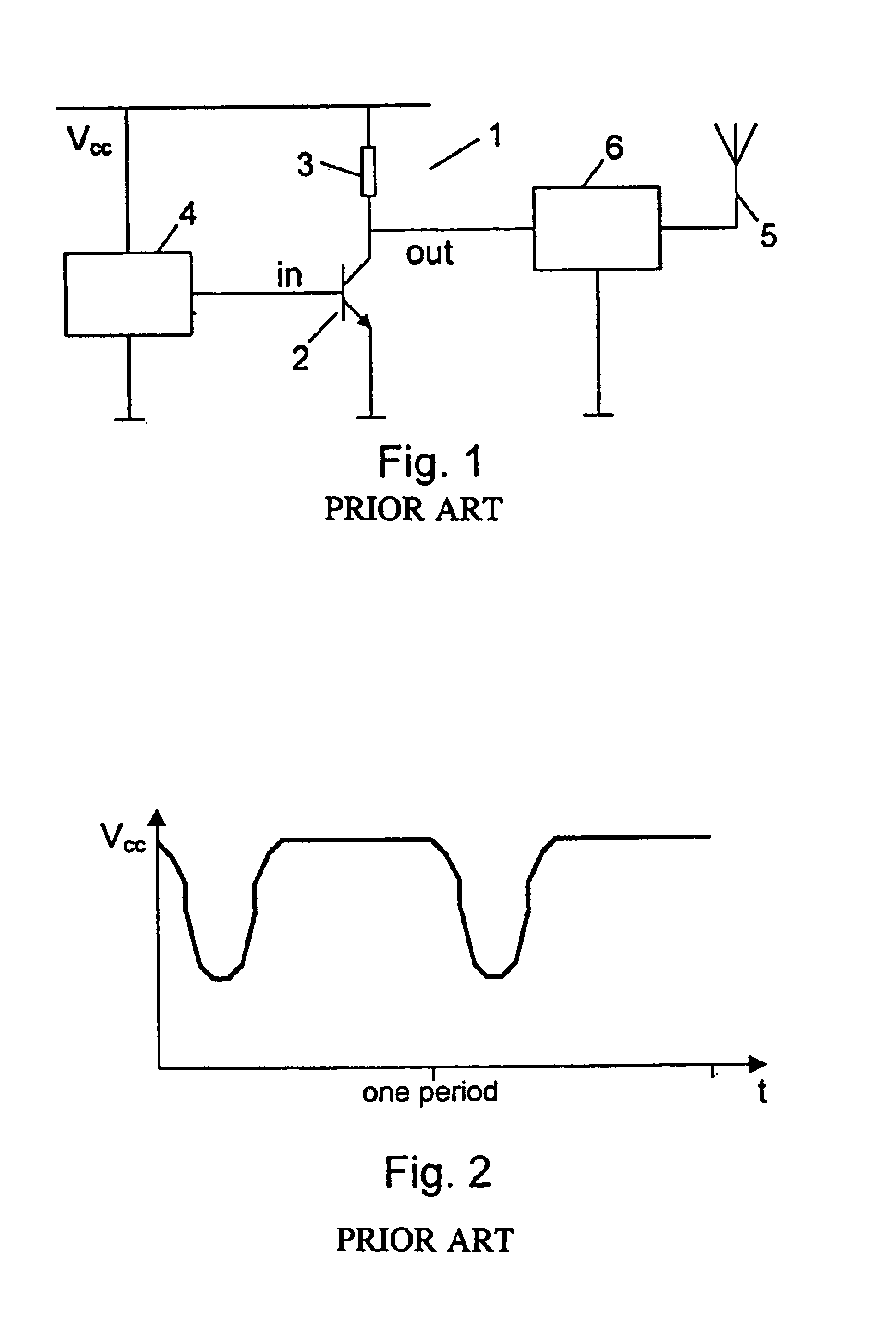

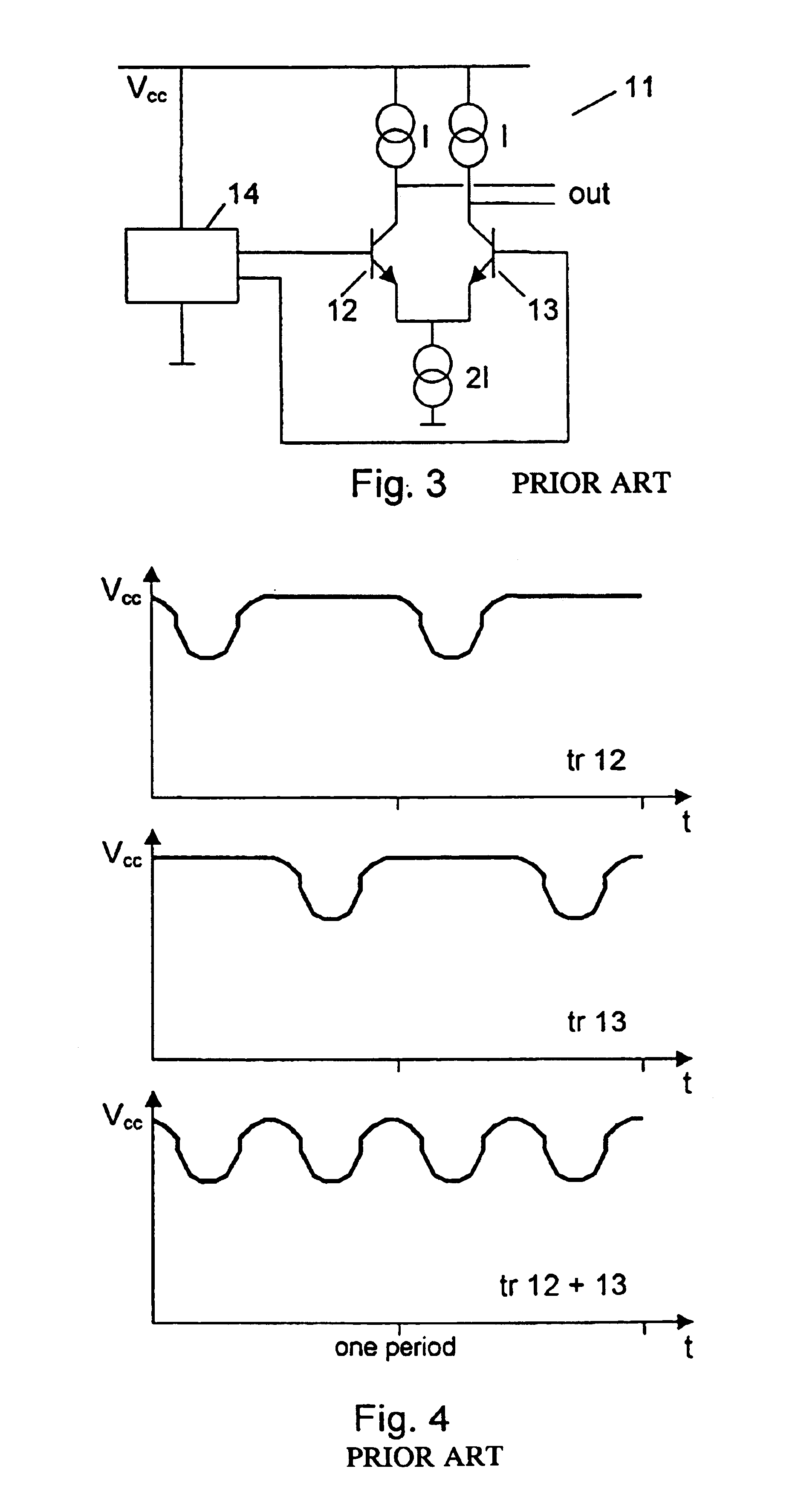

Radio frequency amplifying circuit

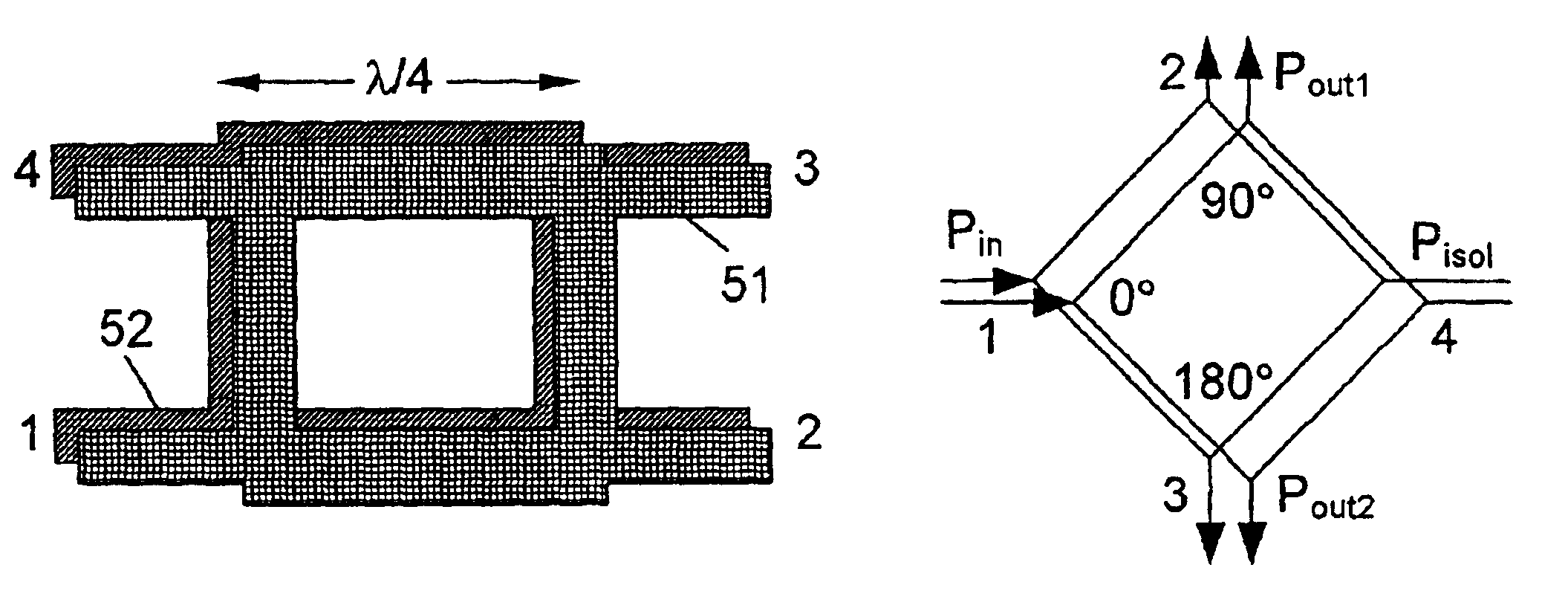

InactiveUS6794953B2Low rippleReduce the ripple amplitudeAmplifiers wit coupling networksWaveguidesHybrid couplerAudio power amplifier

A hybrid coupler (66, 67; 72, 73) has four ports and is capable of coupling radio frequency signals having a certain frequency from at least one port to at least one other port. The hybrid coupler (66, 67; 72, 73) is implemented as a differential coupler arranged to couple differential radio frequency signals. With such a hybrid coupler a power amplifying circuit can be produced which has sufficiently low ripple on the supply voltage to be integrated together with more sensitive radio circuits, and which is also insensitive to load mismatch such that an isolator can be avoided. A differential hybrid coupler allows the output current to be shared between four transistors or amplifiers, thus reducing the amplitude of the ripple. Further, the frequency of the ripple is four times the operating frequency of the circuit, which makes it much easier to filter out the ripple.

Owner:TELEFON AB LM ERICSSON (PUBL)

Production process of high-crystal molecule slow-rebound polyurethane

The invention relates to the technical field of polymer materials, and particularly relates to a production process of polyurethane foam. The production process of high-crystal molecule slow-rebound polyurethane comprises the following steps: 1) storing raw materials, controlling the temperature; 2) conveying the raw materials to a mixing chamber of an assembly line foaming machine, performing low-speed stirring, continuously injecting certain amount of air during the stirring process; 3) conveying the stirred materials to a foaming chamber, performing foaming; 4) conveying the foamed materials to a curing chamber, performing natural curing; 5) conveying the cured polyurethane foam to a treatment platform, and performing post-treatment to obtain the finished product. With the above technical scheme, the slow-rebound polyurethane prepared in the invention is large and uniform in foam pores, has filtration effect after subsequent foam treatment, can be produced continuously by a routine assembly line foaming machine, can increase the production efficiency and reduce the cost, and has more obvious volume advantages when compared with products prepared by conventional processes.

Owner:SHANGHAI GLORY HOME TECH CO LTD +1

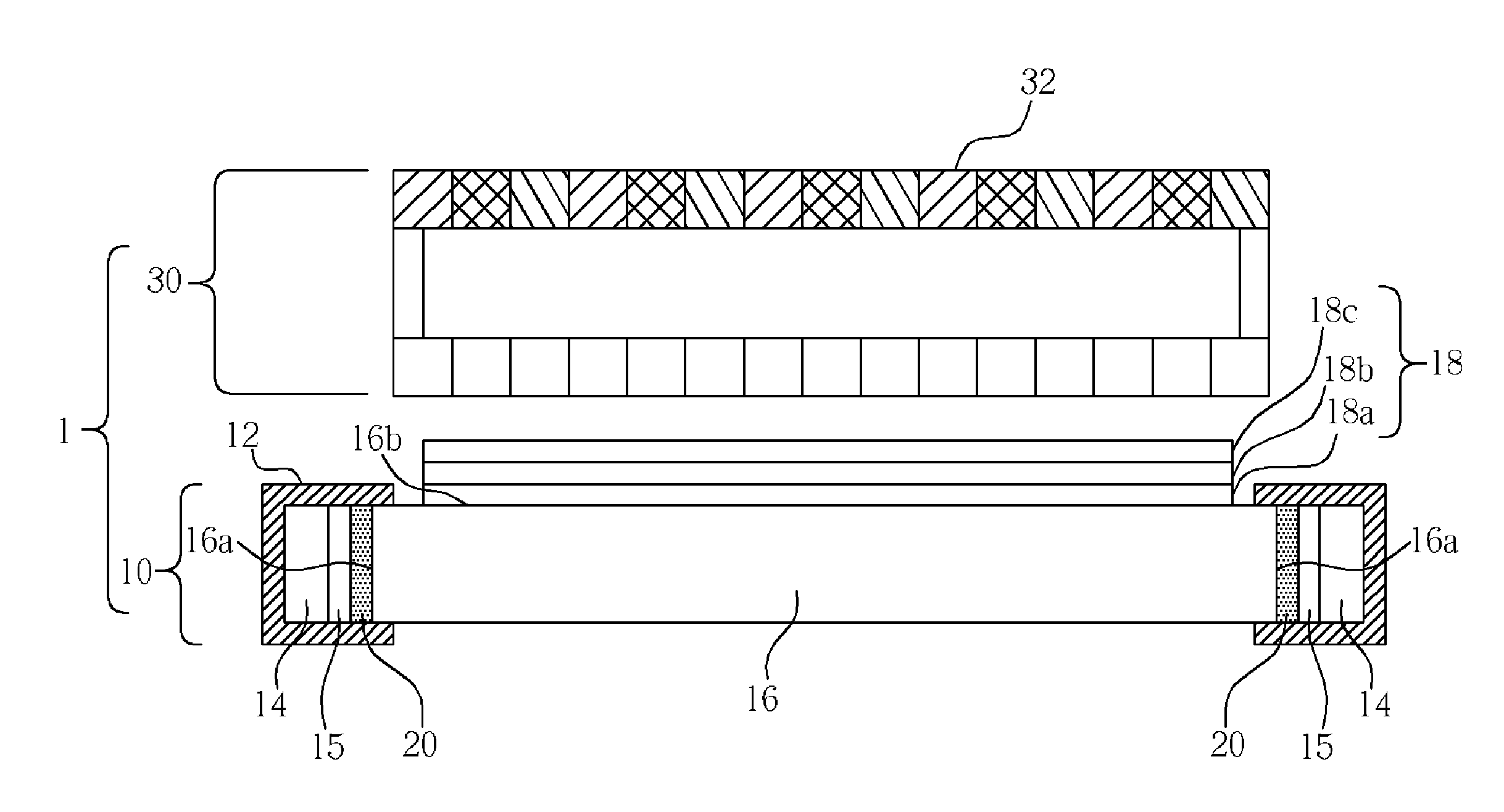

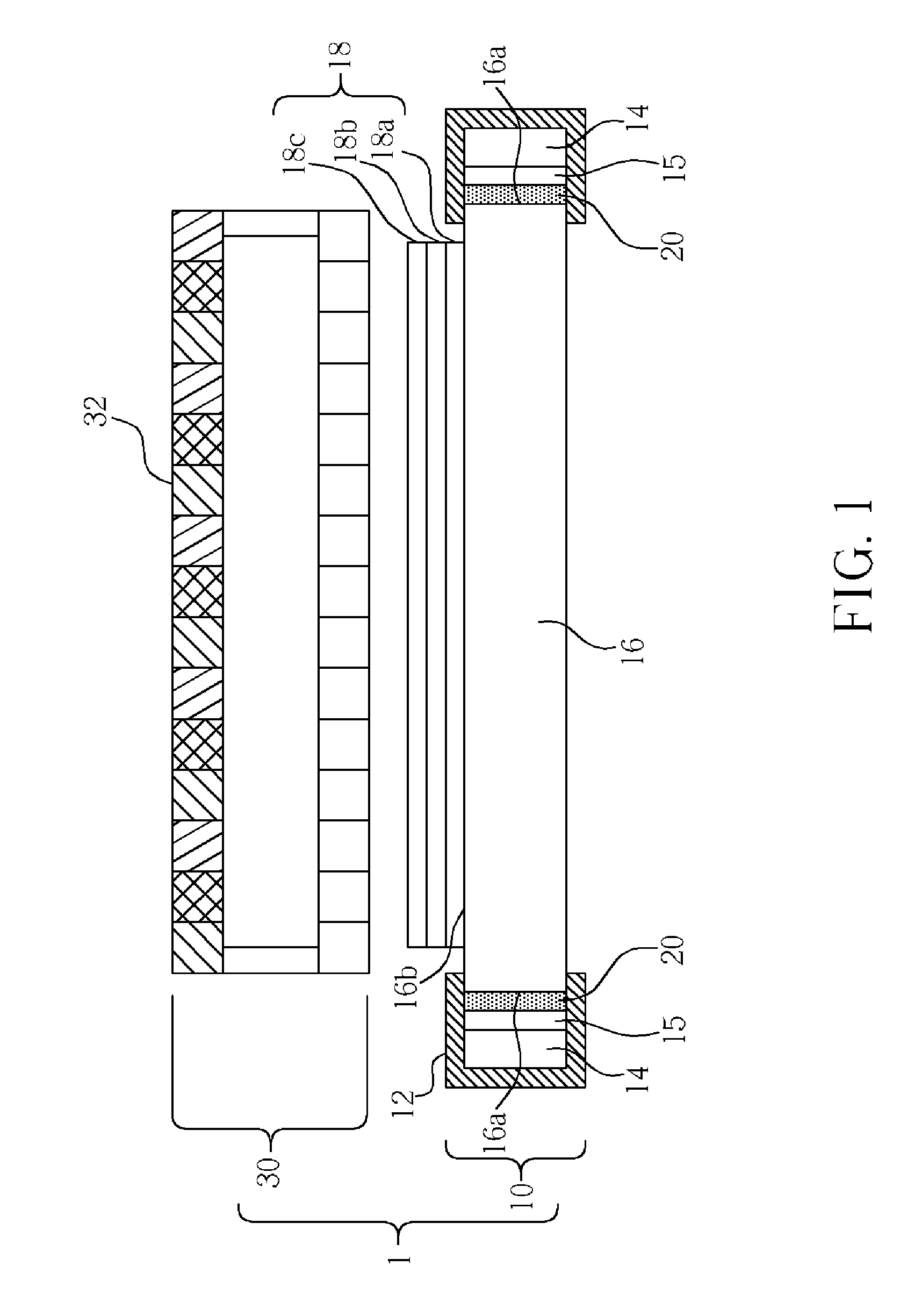

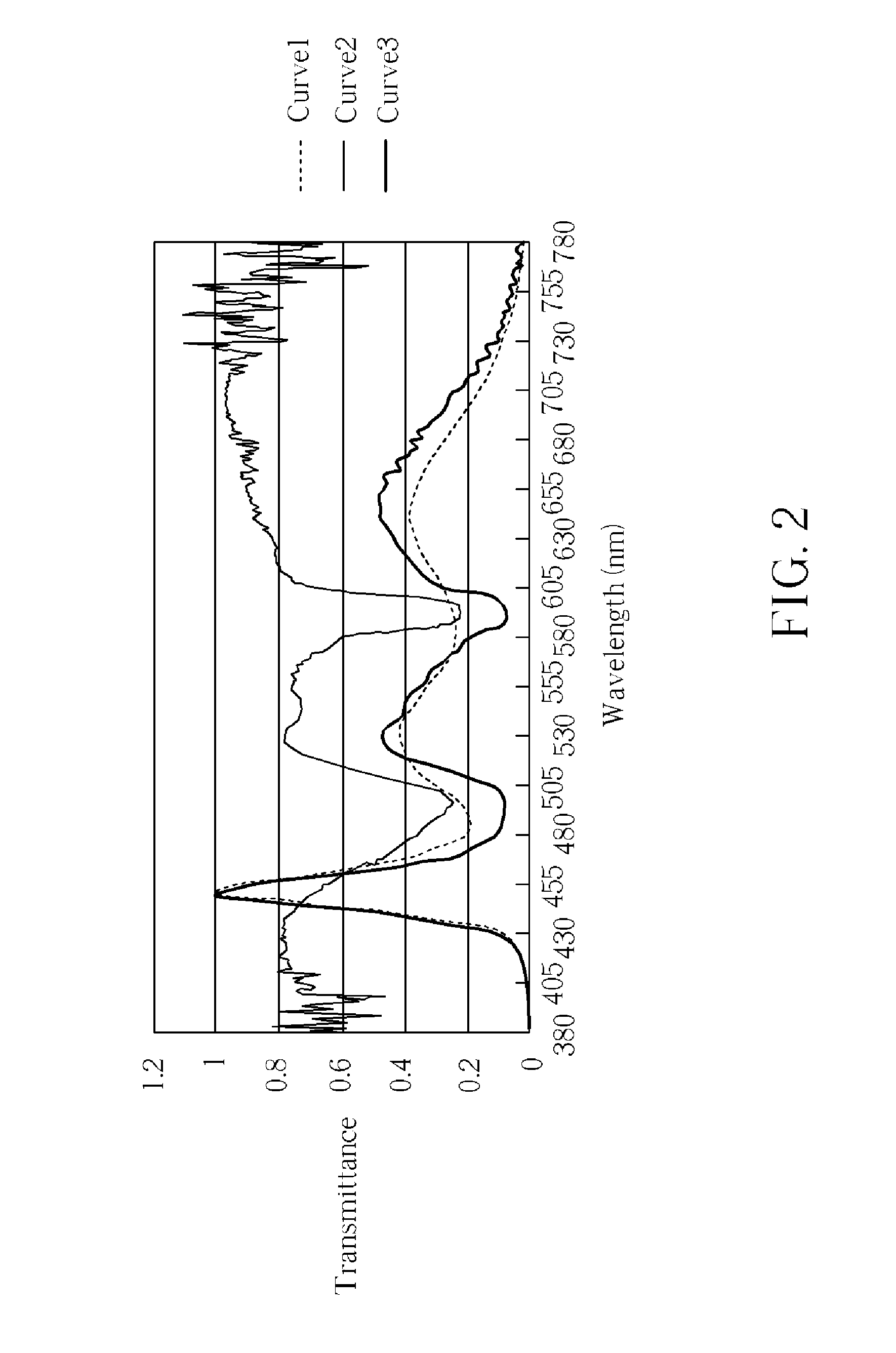

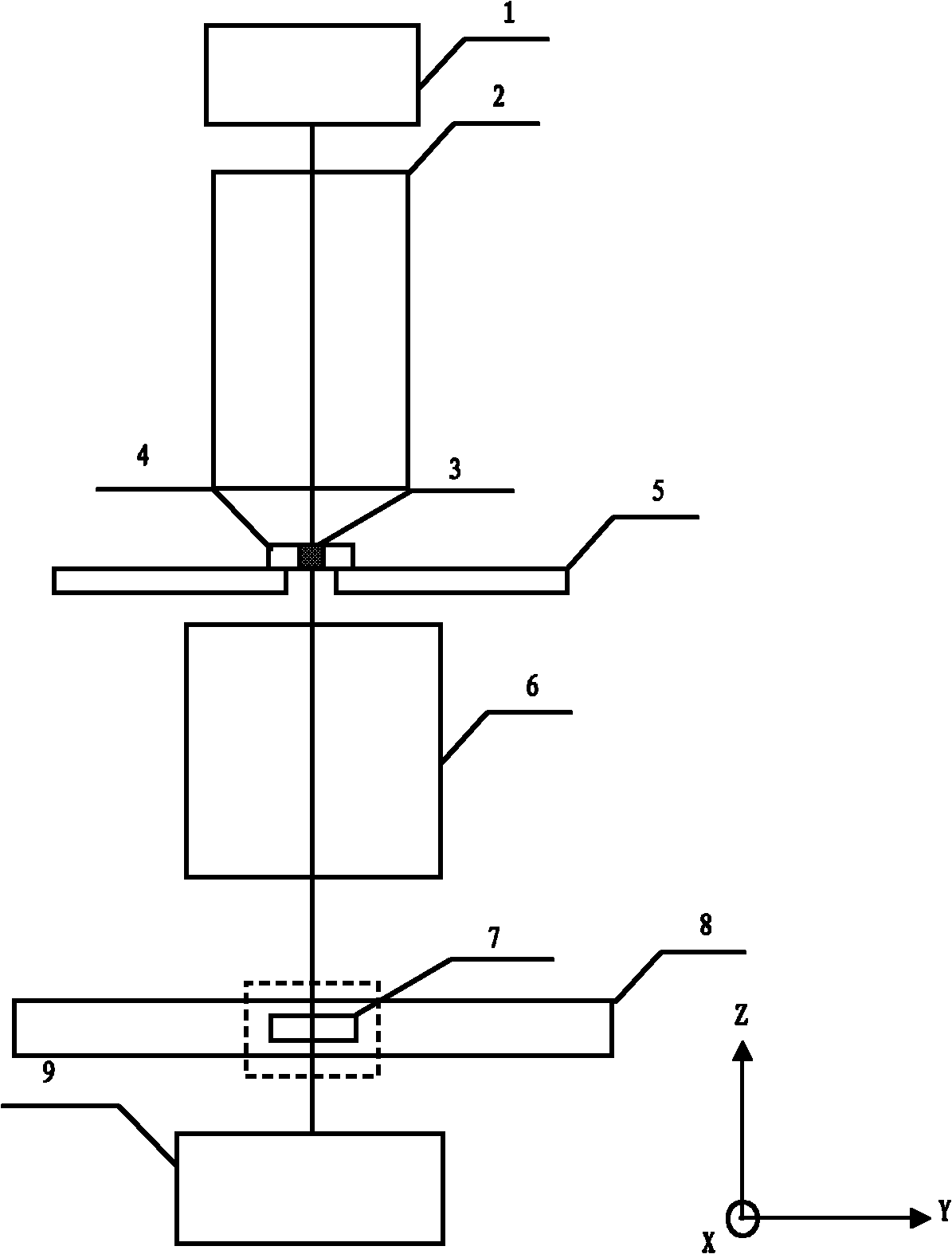

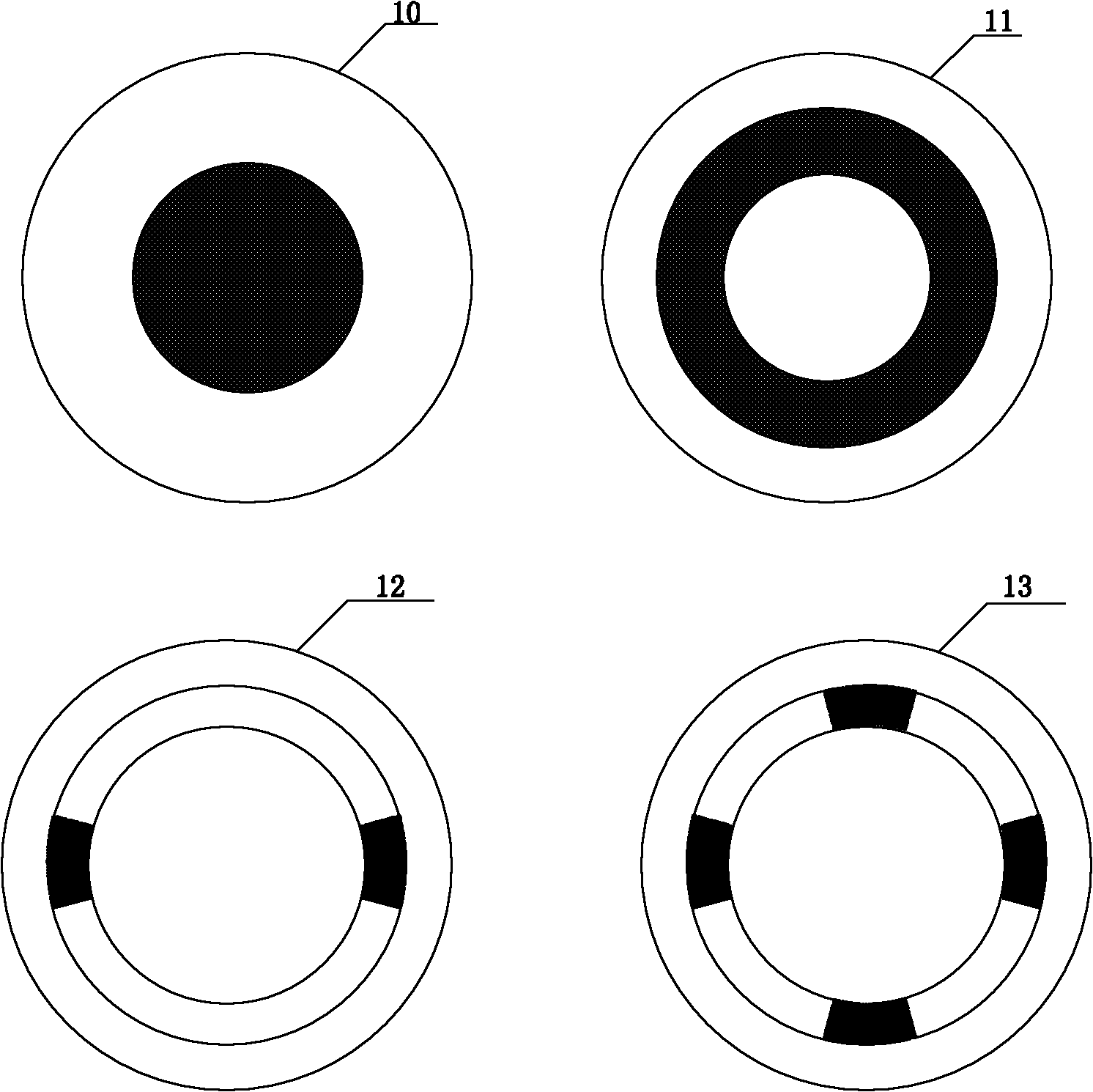

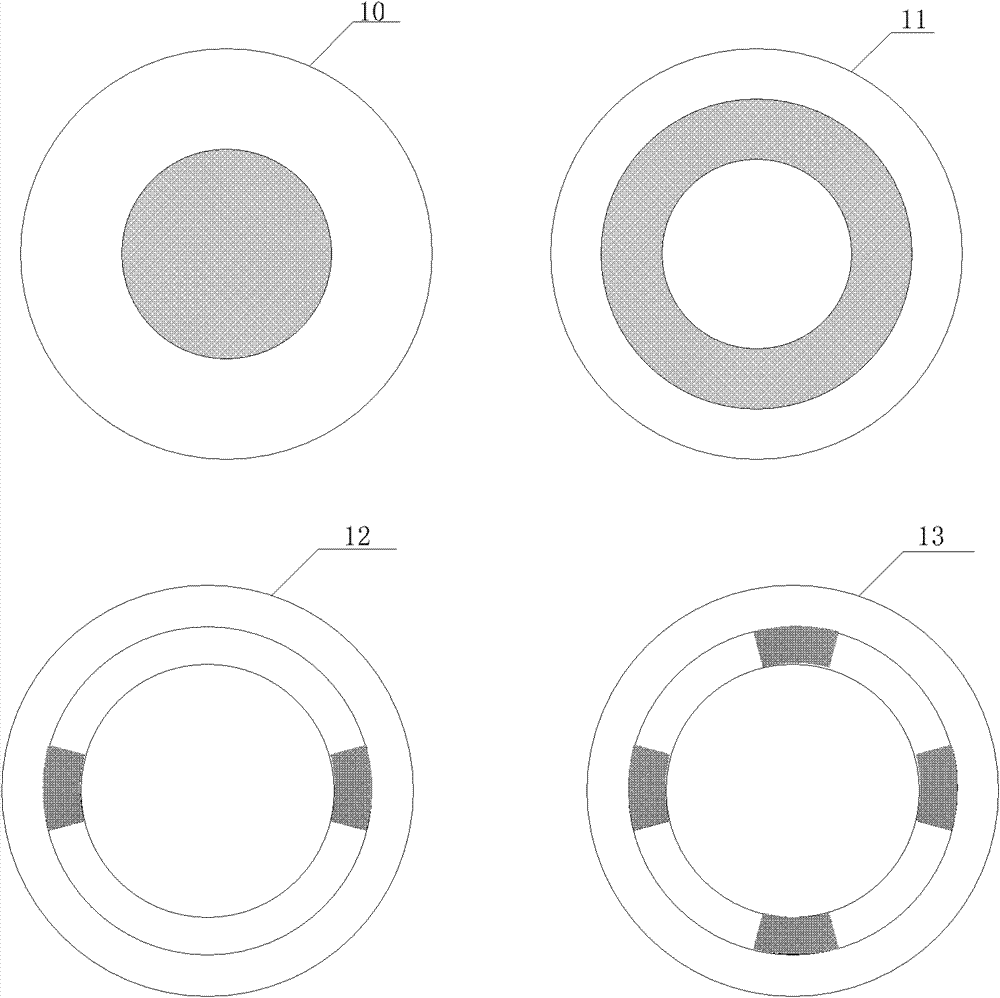

Liquid crystal display device and back light unit thereof

InactiveUS20090180052A1Gamut enhancementEasy to filter outPlanar/plate-like light guidesNon-linear opticsLiquid-crystal displayLight beam

A back light unit adapted to provide light to a liquid crystal display panel includes a housing, at least a light generator, and an optical filter. The light generator is disposed inside the housing for generating white light beams. The optical filter is disposed in an optical path of the white light beams between the light generator and the liquid crystal display panel for filtering the white light beams within a particular wavelength range of visible light. The hue of the white light beams before and after passing through the optical filter are the same.

Owner:AU OPTRONICS CORP

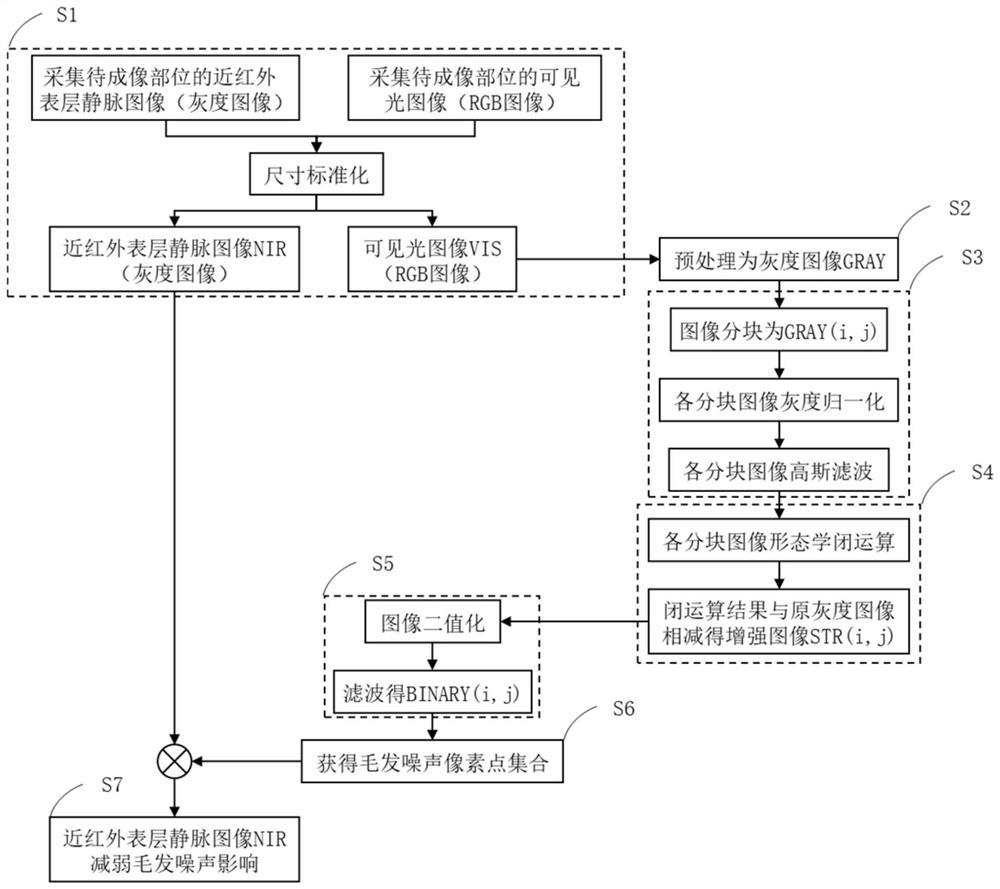

Near-infrared vein image processing method for filtering hair noise

ActiveCN112529800AEasy to identifyAccurate identificationImage enhancementImage analysisImaging processingMedicine

The invention relates to a near-infrared vein image processing method for filtering hair noise, which comprises the following steps: 1) collecting a near-infrared vein image and a visible light imageof a part to be imaged, and carrying out size standardization; 2) graying the visible light image; 3) carrying out blocking, and gray normalization and first filtering on each sub-image after blocking; 4) sequentially performing morphological expansion operation and morphological corrosion operation on each sub-image; performing gray value subtraction operation on each subimage and the corresponding subimage; 5) performing binarization and second filtering on each sub-image; 6) obtaining a coordinate set of hair pixel points; and 7) filtering hair noise of the near-infrared vein image. Compared with the prior art, the invention has the advantages that the specific positions of the hair noise pixel points can be given, the hair noise can be processed more effectively and accurately, and meanwhile damage to vein information in the near-infrared image is small.

Owner:TONGJI UNIV

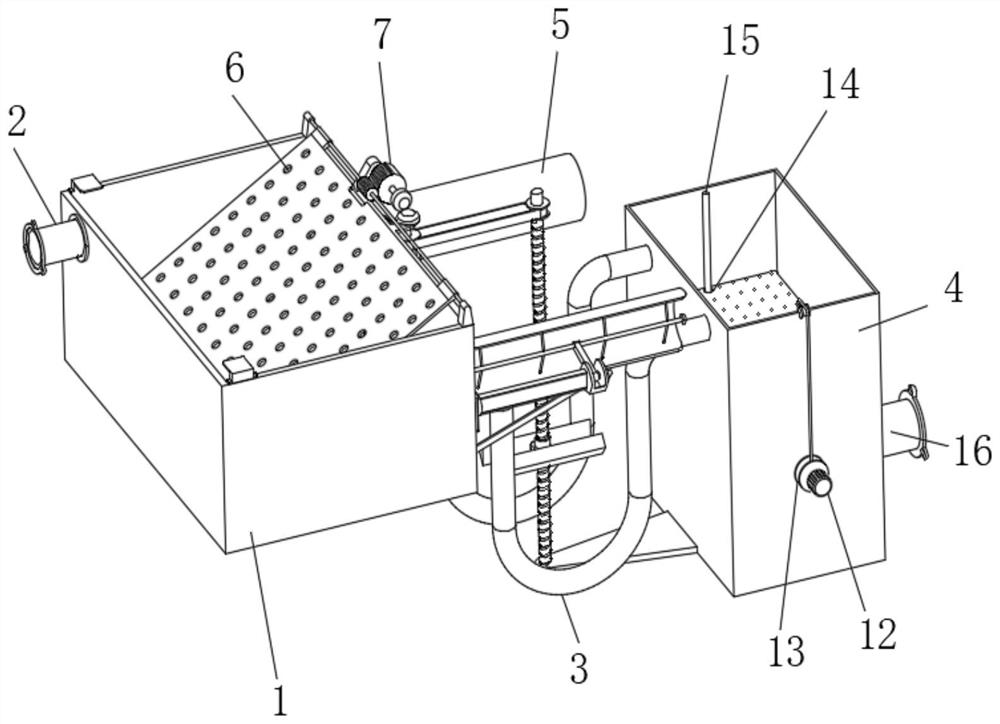

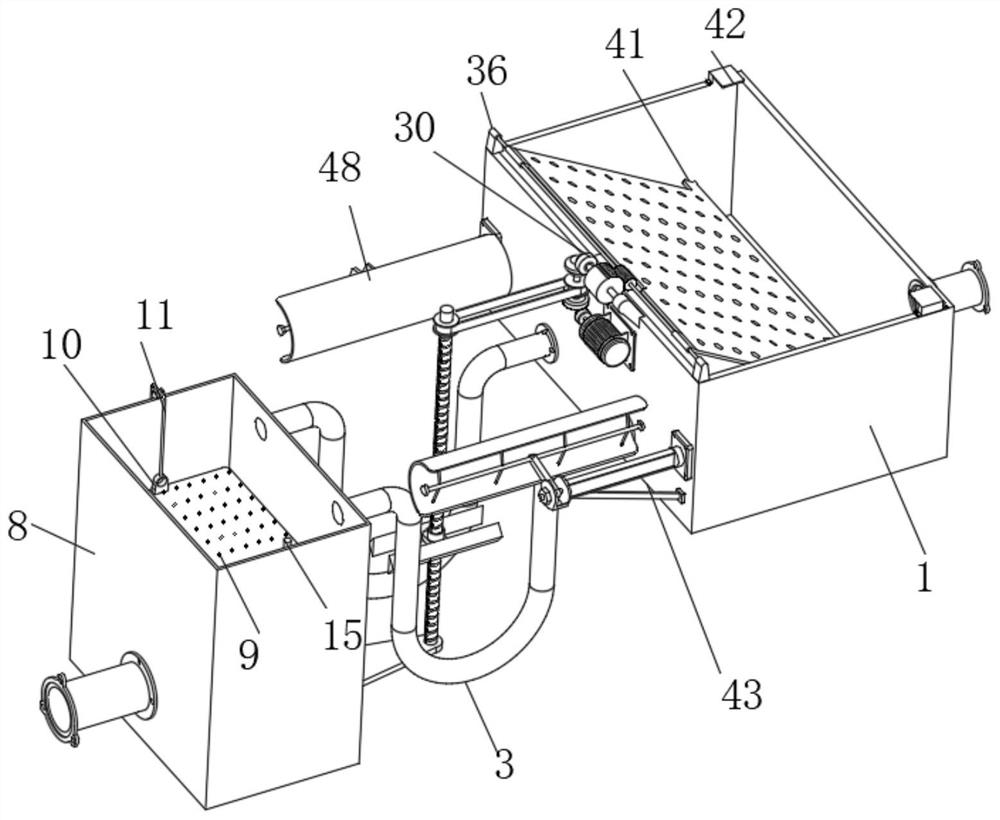

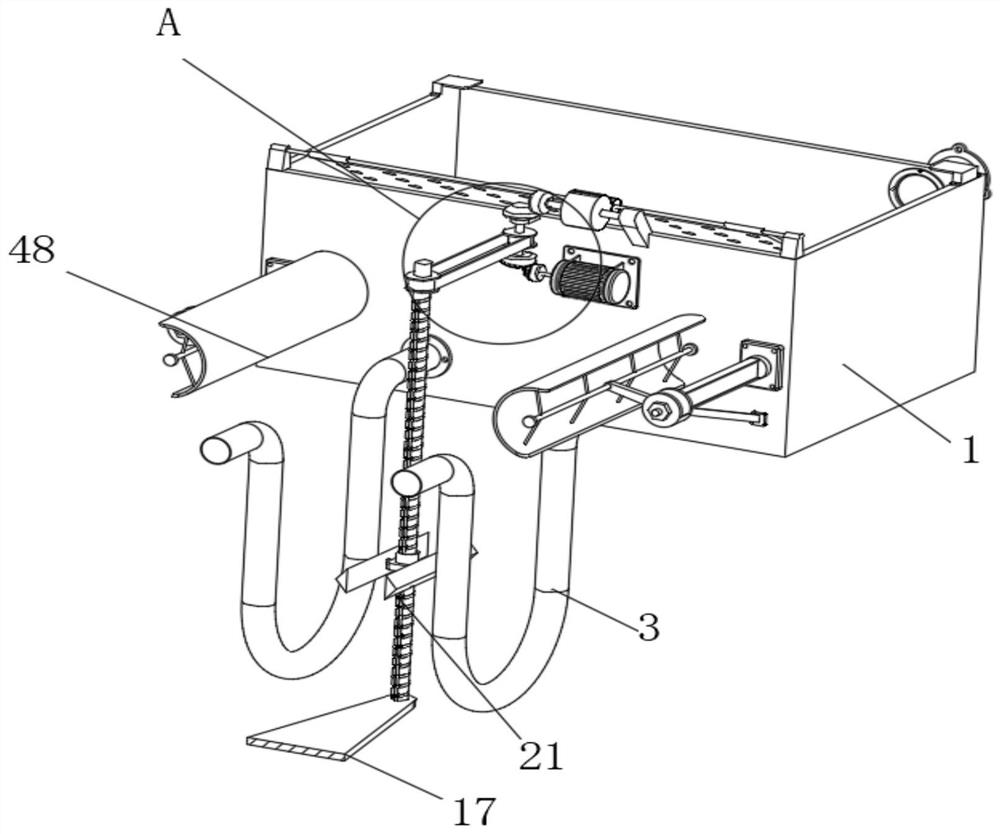

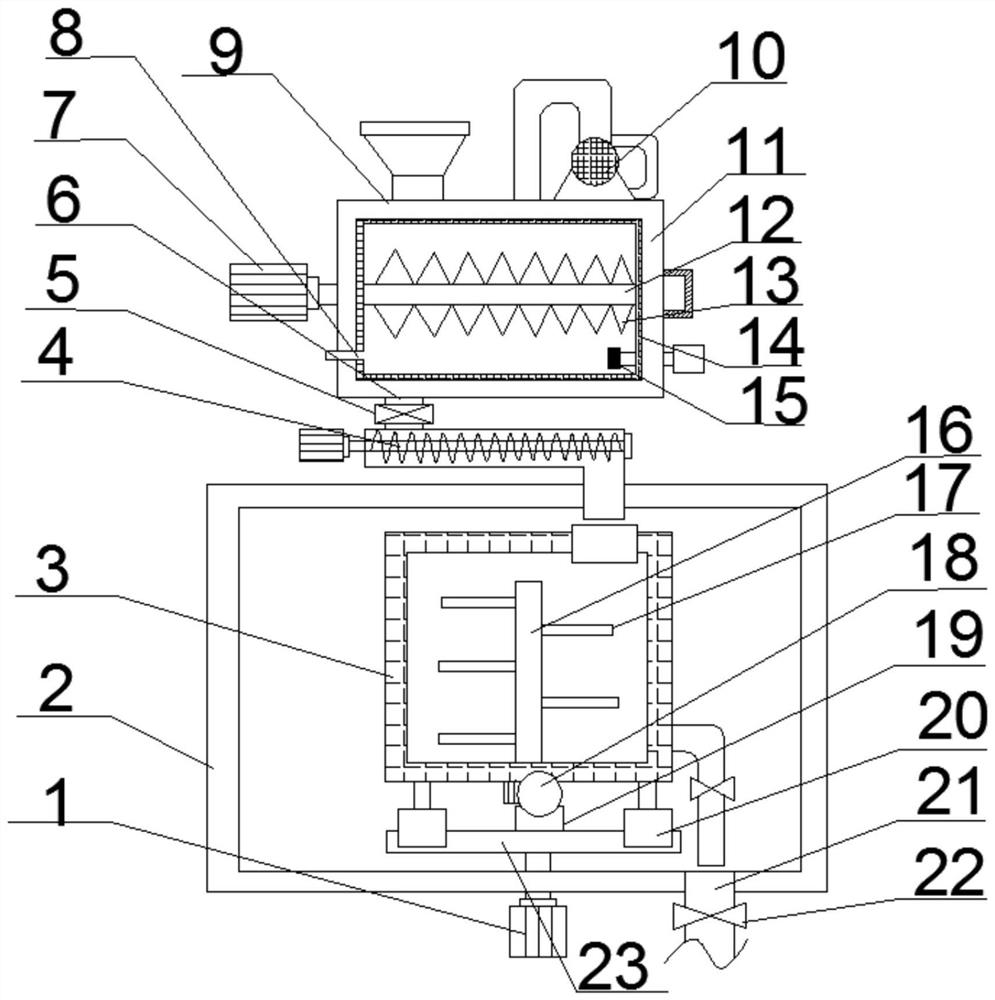

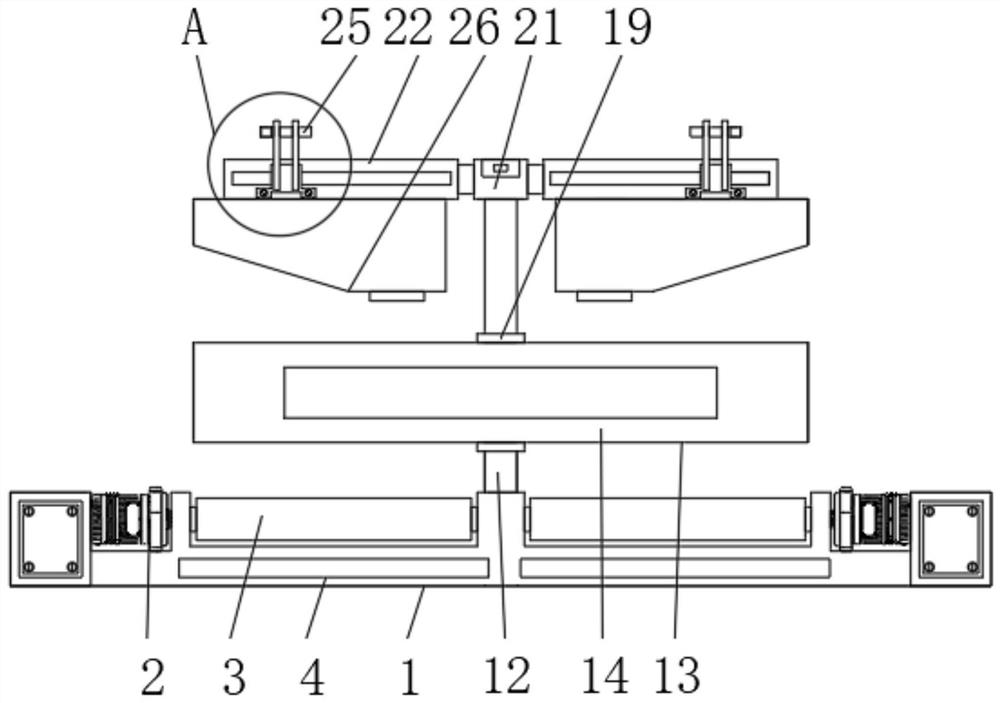

Papermaking wastewater treatment device capable of improving paper pulp recovery rate

InactiveCN113371911APromote decompositionEasy to filter outWater/sewage treatment by irradiationTreatment involving filtrationPapermakingProcess engineering

A papermaking wastewater treatment device capable of improving the paper pulp recovery rate, disclosed in the invention, comprises a sedimentation tank, the far end of the sedimentation tank is communicated with two transparent U-shaped pipelines, the other ends of the two transparent U-shaped pipelines are communicated with a paper pulp extraction assembly, and a solarization assembly is connected between the sedimentation tank and the paper pulp extraction assembly; a filtering piece is connected into the sedimentation tank; and the outer wall of the sedimentation tank is connected with a driving part, and the driving part synchronously drives the filtering part and the solarization assembly. Under the power of the driving part, the solarization assembly is synchronously driven to solarize the two transparent U-shaped pipelines, papermaking wastewater containing a dispersing agent in the transparent U-shaped pipelines is conveniently decomposed, and filtration and propulsion are synchronously carried out in the sedimentation tank, so decomposed papermaking wastewater is filtered and extracted through a paper pulp extraction assembly. The filtered papermaking wastewater is irradiated at high temperature, so that the paper pulp dispersing agent in the papermaking wastewater is conveniently decomposed, filtered and separated out, and the paper pulp recovery during papermaking wastewater treatment is improved.

Owner:LONGYOU COUNTY JINLONG PAPER

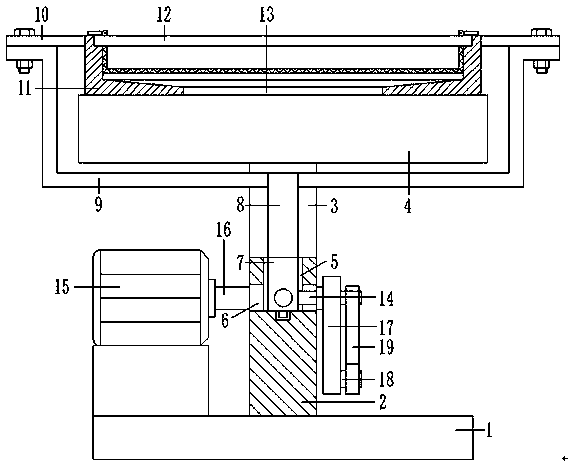

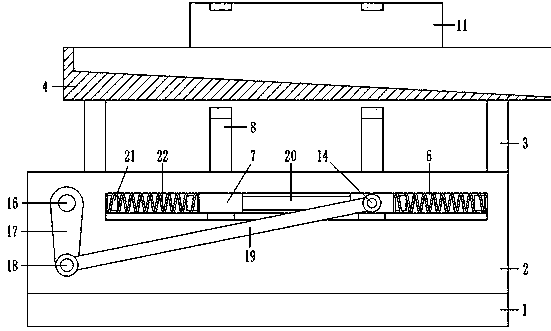

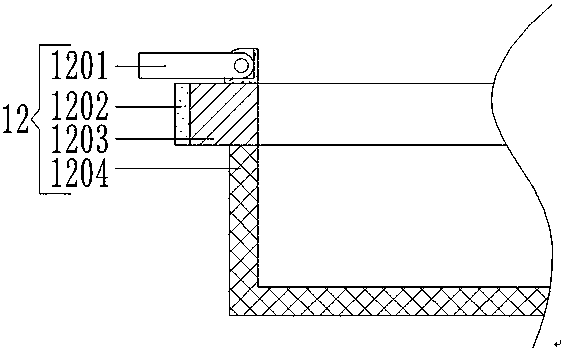

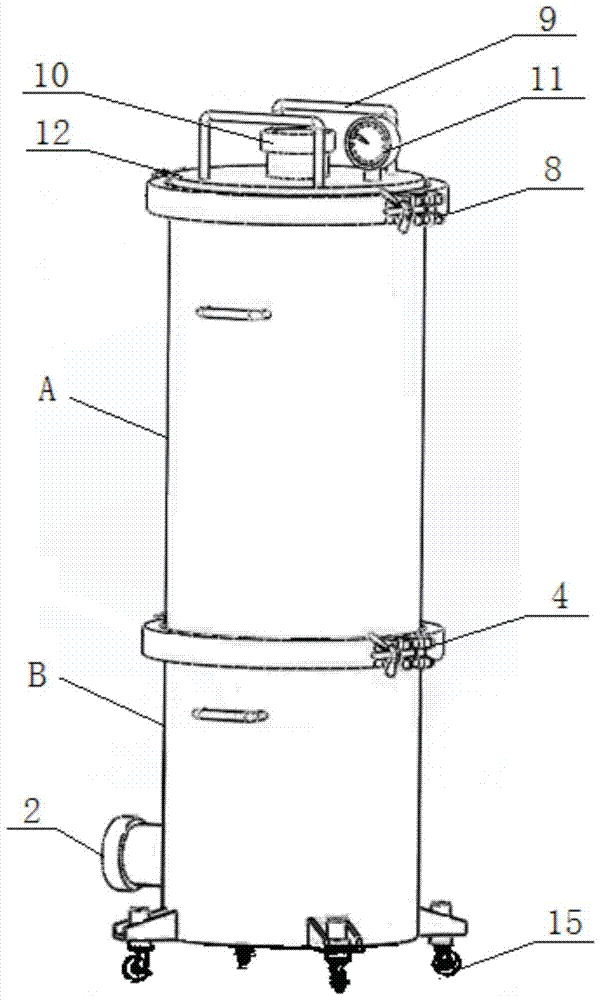

Temporary raw material storage apparatus for eye shadow compact production and processing

PendingCN111776509AGuaranteed qualityImprove the use effectLarge containersTank wagonsProcess engineeringManufacturing engineering

The invention relates to the field of eye shadow compact production and processing, specifically to a temporary raw material storage apparatus for eye shadow compact production and processing. The apparatus comprises a main body, a base, a fixed box, a diaphragm mechanism, a filter mechanism, an isolation mechanism, a separation mechanism and a quantification mechanism; by providing the diaphragmmechanism, the contact between raw materials and parts in the mechanism can be prevented, and lubricating oil and waste chips are prevented from mixing with the raw materials; by providing the filtermechanism, impurities in the raw materials can be screened and eliminated, and the impurities attached to a filter plate are backwashed to achieve the self-cleaning effect; by providing the isolationmechanism, the position of a floating plate is automatically adjusted according to the quantity of the raw materials stored in the main body, and gas can be conveniently isolated from contacting the raw materials to guarantee the quality of the raw materials; by providing the separation mechanism, the passing of the raw materials is convenient, and the gas is prevented from entering; and by providing the quantification mechanism, the raw materials can be quantitatively taken to prevent waste caused by excessive taking.

Owner:义乌市美硕塑胶制品股份有限公司

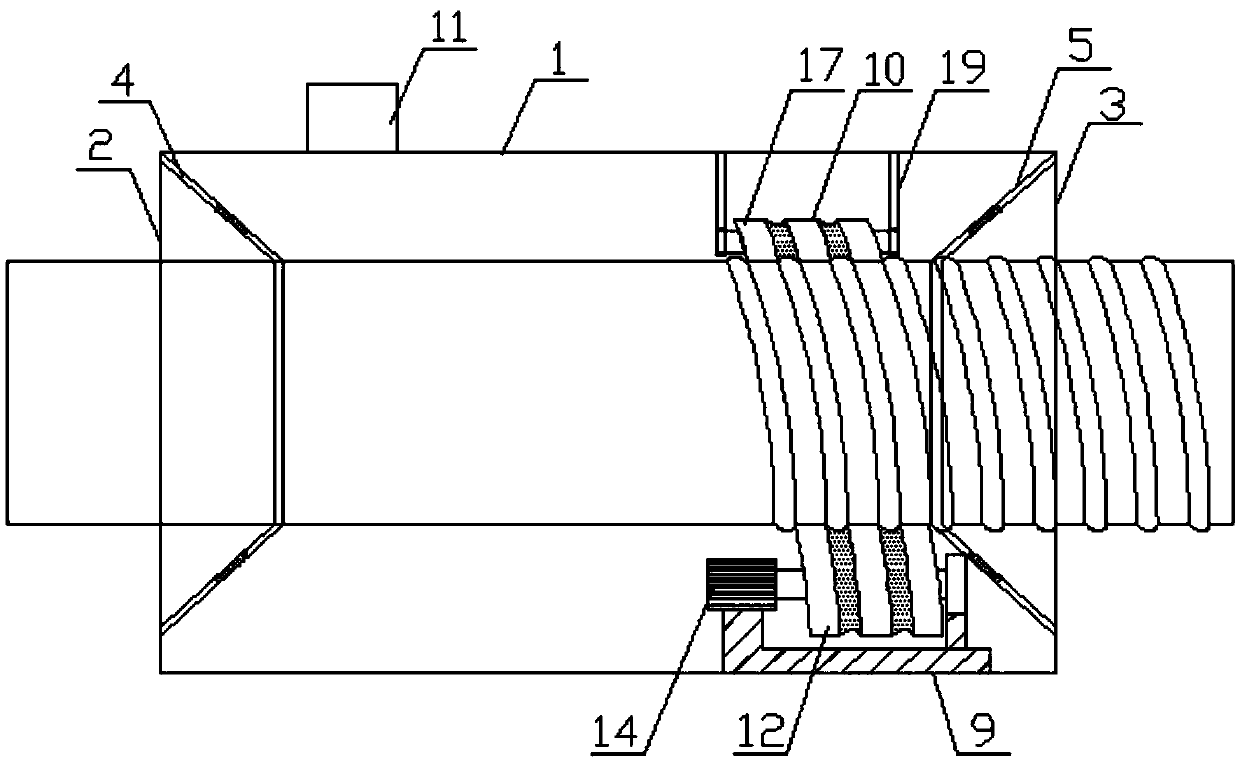

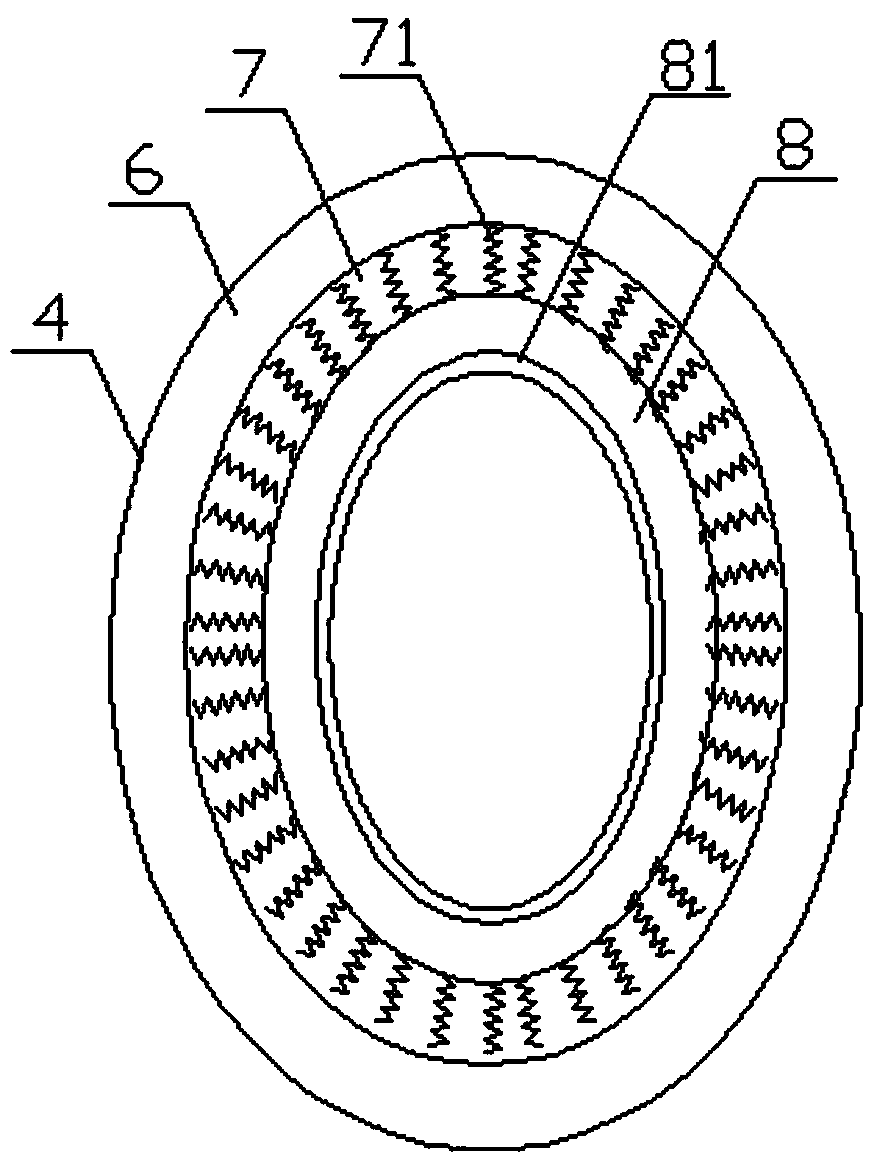

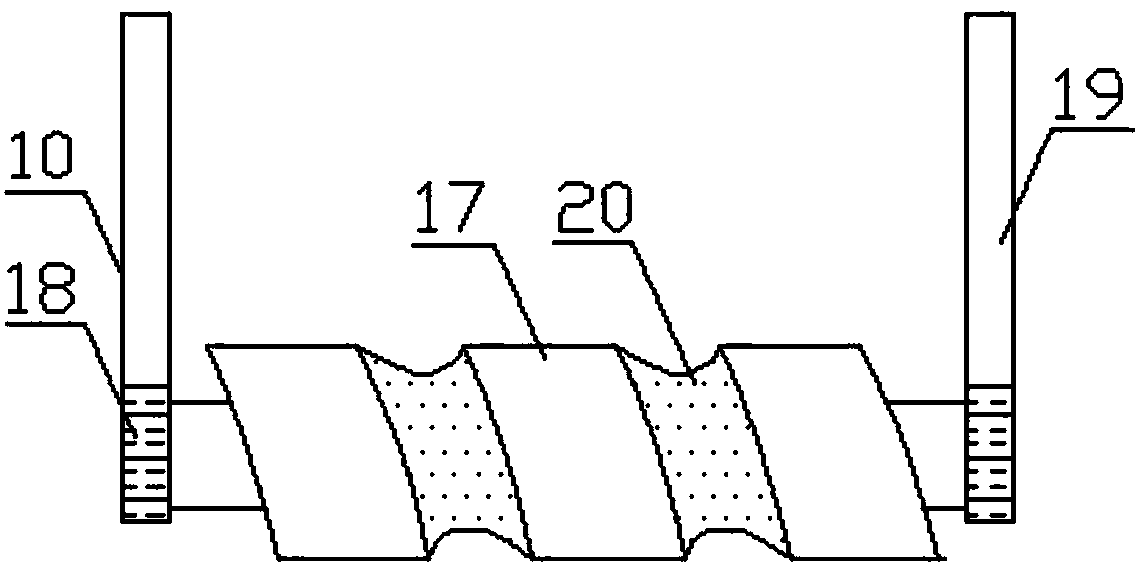

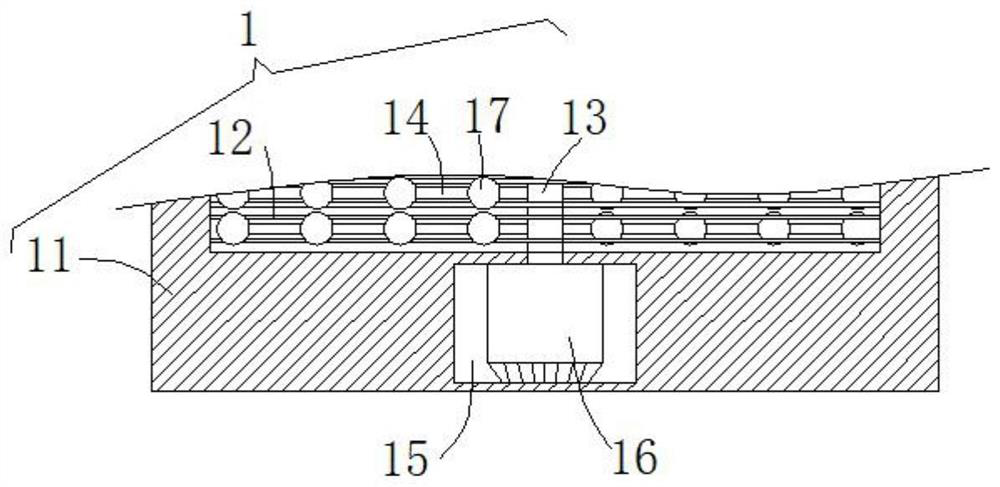

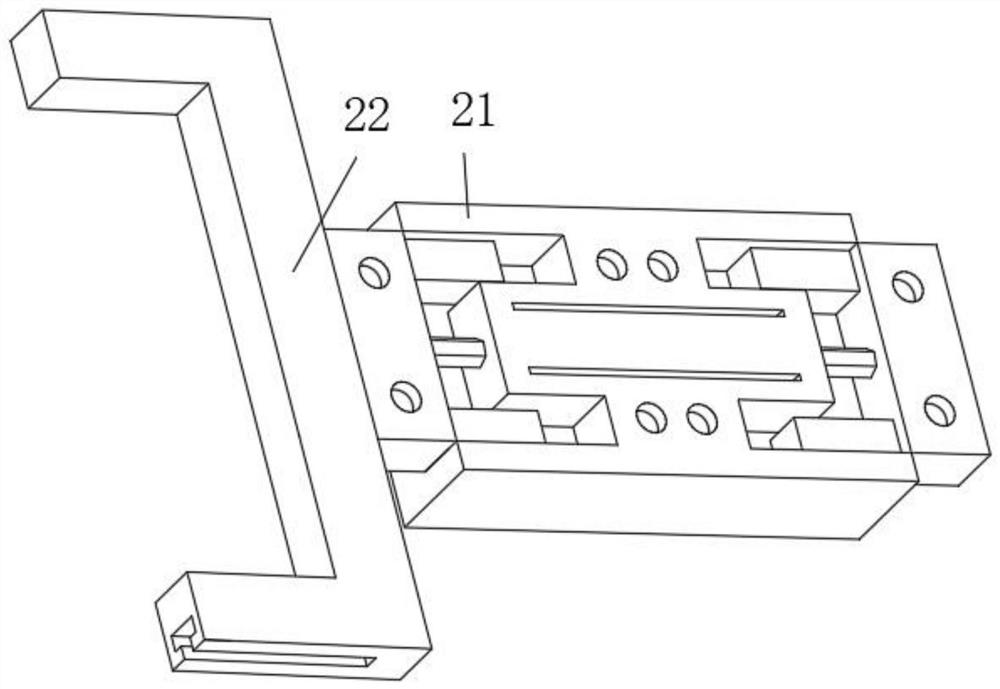

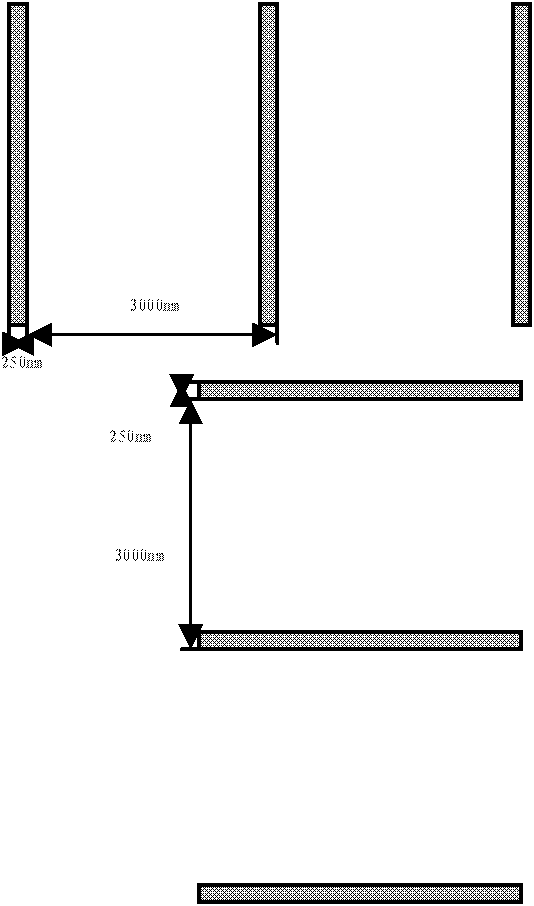

Exhaust equipment for full-coating of polyethylene spirally enwound structure-wall pipe

The invention discloses exhaust equipment for full-coating of polyethylene spirally enwound structure-wall pipe. The exhaust equipment comprises a full-coating machine head, one end of the full-coating machine head is provided with a pipeline inlet, and the other end of the full-coating machine head is provided with a pipeline outlet; and a first sealing sleeve is arranged on the pipeline inlet side, and a second sealing sleeve is arranged on the pipeline outlet side. According to the exhaust equipment, the first sealing sleeve and the second sealing sleeve are used for sealing the equipment,a vacuum pump is used for vacuumizing in the pipe machining process so that the effect that the quality and the appearance of a pipe are influenced because bubbles are generated in the process of winding a flat pipe can be avoided, and the high-quality pipe can be produced; the pipe with the flat pipe wound is shaped through a shaping device, the pipe with the flat pipe wound is shaped and rolled,the surface of the pipe with the flat pipe wound is pressed to be a smooth surface, the appearance is attractive, and the bubbles can be conveniently and quickly discharged; and the pipe subjected toshaping undergoes bubble pressing and shaping again through a bubble pressing device, the structure is simple, the production processes of pipe exhausting and winding are completed, and the high-quality large-caliber polyethylene spirally enwound structure-wall pipe can be produced.

Owner:ANHUI PROVINCE ZHONGYANG PIPE IND

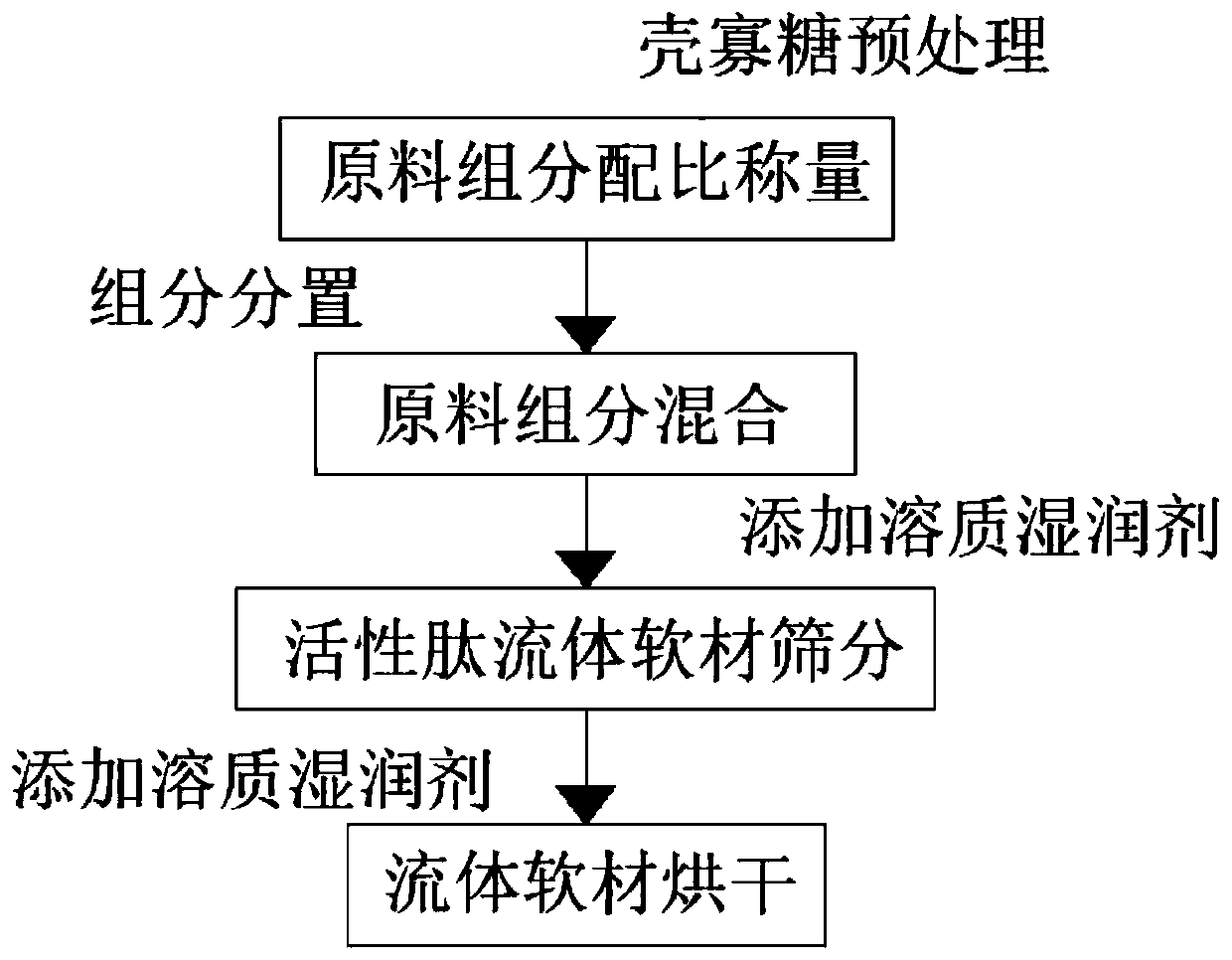

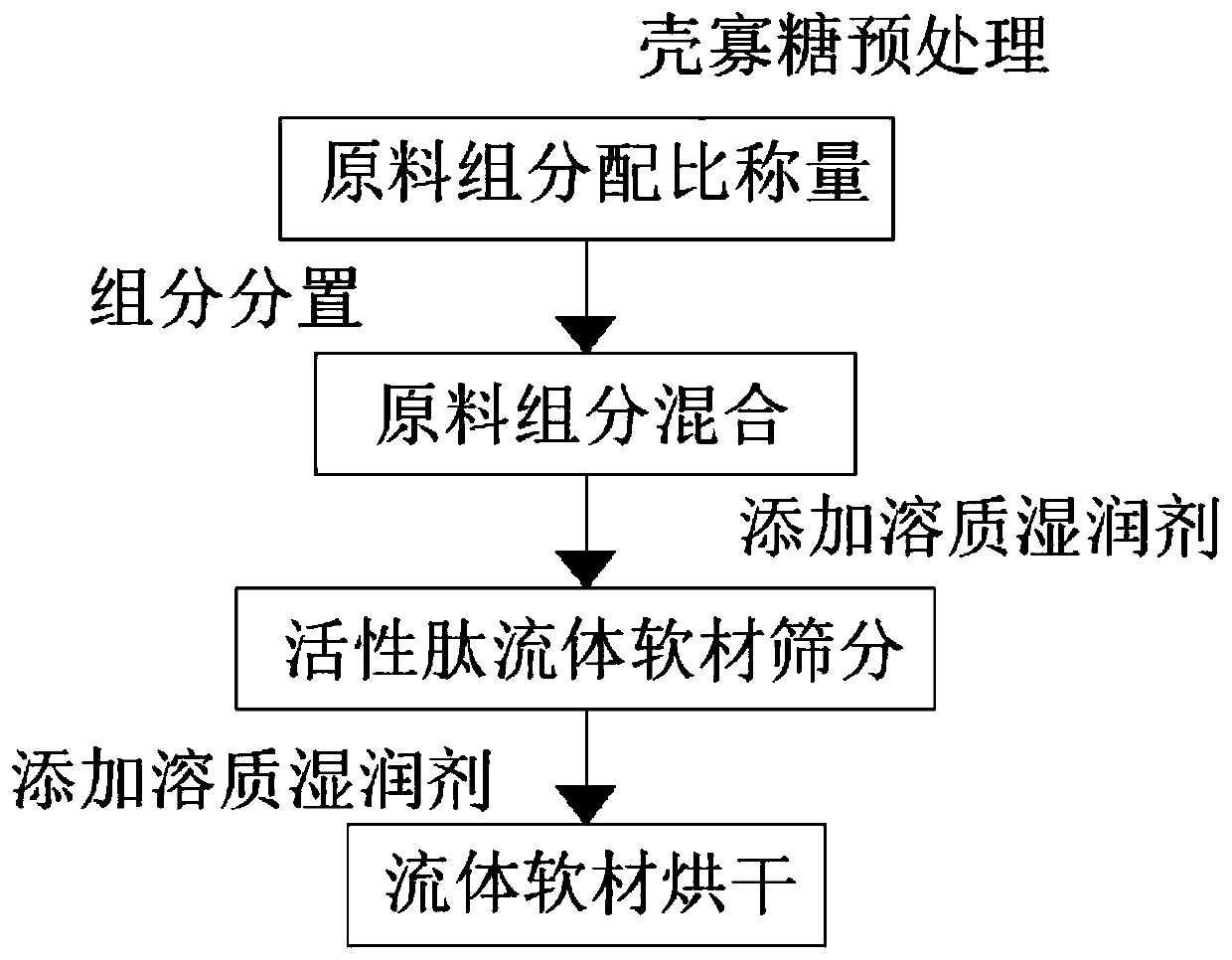

High-efficacy micromolecule soybean protein bioactive peptide solid beverage and formula thereof

InactiveCN110012992AStrengthen the immune systemIncrease the content of positively charged ionsStationary filtering element filtersFood scienceIngested foodIon

The invention discloses a high-efficacy micromolecule soybean protein bioactive peptide solid beverage and a formula thereof, and belongs to the field of foods. According to the high-efficacy micromolecule soybean protein bioactive peptide solid beverage and a formula thereof, the high-efficacy micromolecule soybean protein bioactive peptide solid beverage comprises components of soybean peptide,chitosan oligosaccharide, a sweetening agent, a sour agent, tea powder, vitamin B, glucose, saccharin sodium and citric acid. The soybean peptide can be complemented for human bodies, besides, chitosan oligosaccharide components lacking in human bodies can be complemented, comprehensive energy can be produced, human body cells are repaired, the immune system of the human bodies is strengthened, the content of positive charge ions in the human bodies is increased, promotion of the absorption level of the soybean peptide by staff taking the soybean peptide is facilitated, reduction of waste of the taken soybean peptide is facilitated, besides, excessive static electricity generated by the human bodies is reduced, and the safety of technical staff in a part of working environment needing avoiding electric arcs is promoted.

Owner:余丰福

Screening device and screening method for production of composite stabilizer

Owner:南京金陵化工厂有限责任公司

Low-concentration flue gas desulfurization method for hydroelectric silicon smelting

ActiveCN109482048AReduce emission concentrationReduce generationDispersed particle separationParticulatesSorbent

The invention discloses a low-concentration flue gas desulfurization method for hydroelectric silicon smelting. The method comprises the following steps: 1) preparing absorption slurry, namely fully uniformly mixing a desulfurization adsorbent ground to the granularity of 325-400 meshes and water so as to obtain the absorption slurry; 2) absorbing acid gas, namely enabling the absorption slurry and flue gas to be fully contacted in a desulfurizing tower when flue gas during hydroelectric silicon smelting enters a desulfurization system, so that acid gas and particles in the flue gas are absorbed by the absorption slurry; and 3) discharging the flue gas, namely detecting the emission concentration of SO2 at the outlet, discharging the SO2 while meeting requirements, if not, returning to thedesulfurization system to treat, filtering the absorption slurry after absorption, and returning the filtrate to the step (2) to serve as absorption liquid, and taking the filter residues as by-products for sales, thereby obtaining the product. According to the method disclosed by the invention, limestone and other desulfurization adsorbents are mixed with water to prepare the absorption slurry,the flue gas enters the desulfurization system to be fully contacted with the slurry, and the acid gas and particles are removed, so that the emission concentration of sulfur dioxide in the flue gas is reduced to 80mg / Nm3, and green and environmental-friendly production is effectively realized.

Owner:云南永昌硅业股份有限公司

Screening device for fertilizer production and screening method thereof

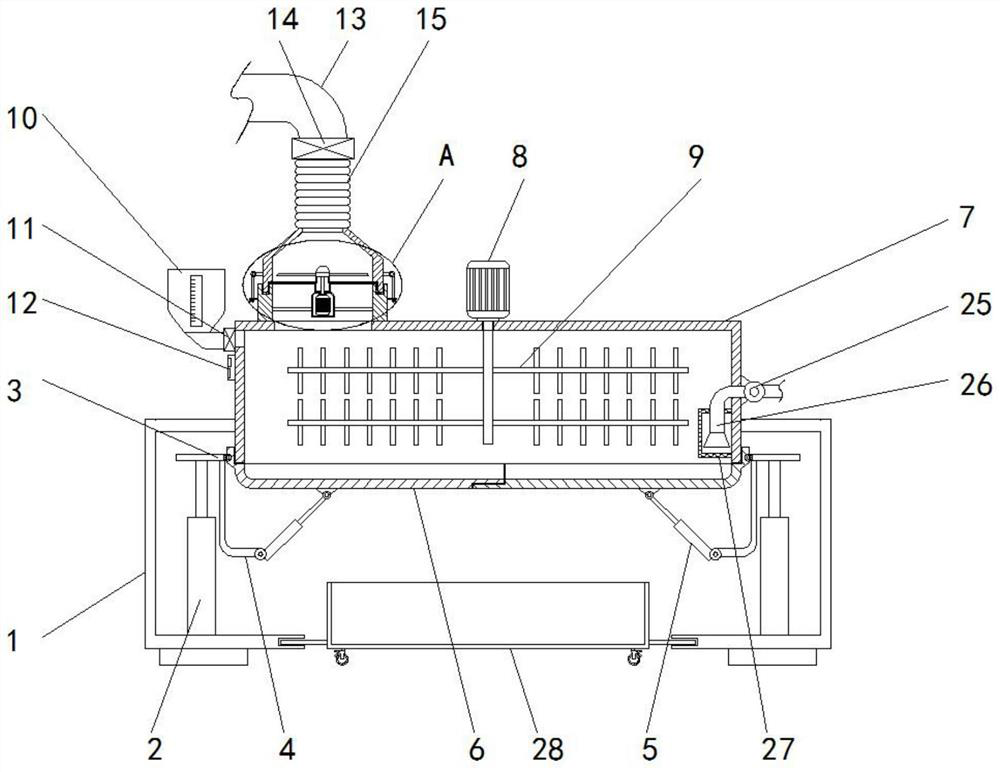

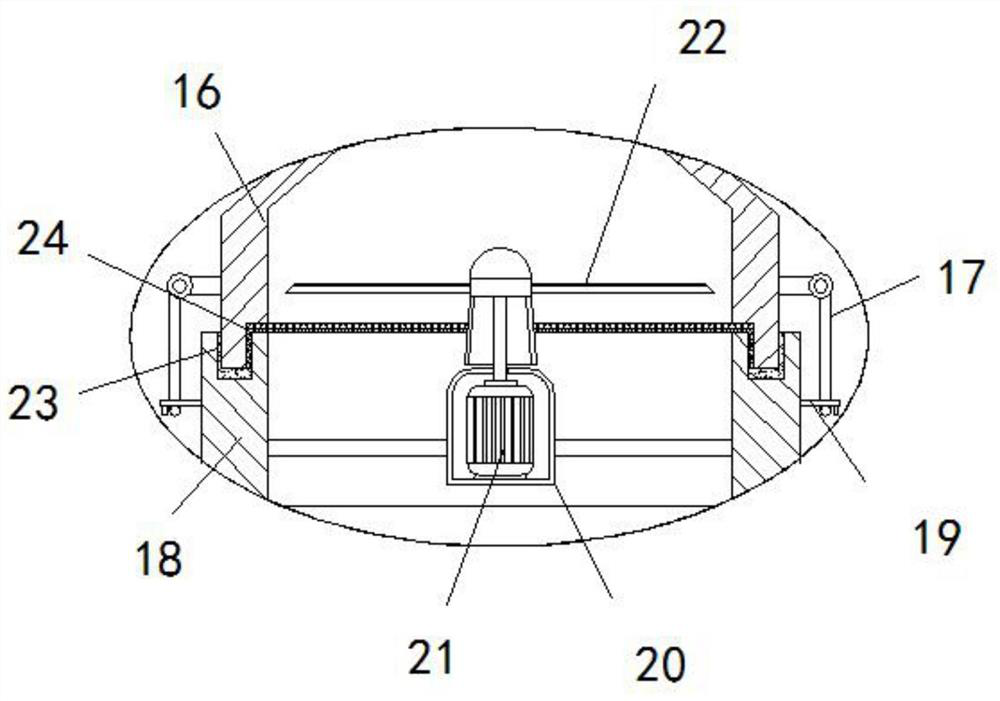

PendingCN112058662AAchieve dryingAchieve sievingSievingGas current separationAgricultural scienceAgricultural engineering

The invention relates to the technical field of fertilizer production equipment, in particular to a screening device for fertilizer production and a screening method thereof. The screening device forfertilizer production comprises a screening bin, a screen cylinder is connected into the screening bin, a driving structure for driving the screen cylinder to rotate is connected to the bottom of thescreen cylinder, a drying structure is connected to the top of the screening bin, the drying structure comprises a drying bin connected to the top of the screening bin through a conveying pipe, an electromagnetic valve is connected to the conveying pipe, a heating cavity is formed by the inner wall and the outer wall of the bin wall of the drying bin and connected with a hot air pump, a pluralityof hot air ports are formed in the heating cavity, an exhaust port is formed in the drying bin, a stirring structure is connected into the drying bin, the bottoms of the screen cylinder and the screening bin are separately connected with discharge pipes, and the discharge pipes are connected with electric control valves, and the screening method of the screening device is characterized in that after fertilizer is dried, and then screening treatment is carried out. The problem that an existing screening device is extremely low in screening efficiency is solved, the fertilizer is prevented frombeing bonded in the screening process through the screening device, and the screening efficiency is improved.

Owner:四川中农润泽生物科技有限公司

Environment-friendly sewage treatment device and sewage treatment method

InactiveCN113058945AEasy to cleanAvoid cloggingHollow article cleaningTreatment involving filtrationSludgeElectric machinery

The invention relates to the technical field of sewage treatment, and discloses an environment-friendly sewage treatment device which comprises two supporting frames and a sewage pipeline. First hydraulic push rods are fixedly connected to the inner sides of the supporting frames, supports are fixedly connected to the top ends of the first hydraulic push rods, extension frames are fixedly connected to the bottoms of the supports, second hydraulic push rods are hinged to the opposite sides of the two extension frames, and bottom covers are hinged to the opposite sides of the two supports. A treatment box is fixedly connected between the opposite sides of the two supporting frames, a stirring motor is fixedly connected to the top of the treatment box, a stirring paddle is fixedly connected to an output shaft of the stirring motor, an electric valve is fixedly connected to the left side of the treatment box, and a chemical dosing barrel is fixedly connected to the left side of the electric valve. According to the environment-friendly sewage treatment device and a sewage treatment method, clotted sludge can be conveniently dispersed, waste can be conveniently crushed, chemical dosing can be automatically performed, and precipitated sludge and waste can be conveniently cleaned away.

Owner:史伟康

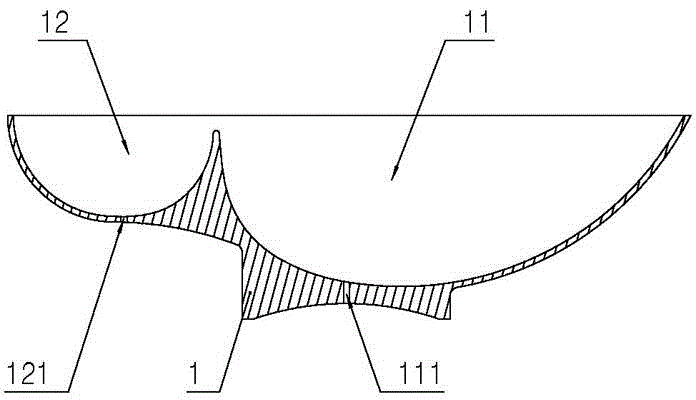

Dish plate

The invention discloses a dish plate accommodating dishes and seasonings independently and directly. The dish plate comprises a plate body; at least one auxiliary accommodating cavity used for accommodating seasonings and at least one main accommodating cavity used for accommodating dishes are arranged in the plate body, and the space of the main accommodating cavity is larger than that of auxiliary accommodating cavity. Since the auxiliary accommodating cavity used for accommodating seasonings and the main accommodating cavity used for accommodating dishes are arranged independently, the dishes and seasonings can be accommodated in the main accommodating cavity and the auxiliary accommodating cavity respectively, and usage is facilitated; the dish plate is particularly adaptive to accommodation of dishes such as steamed eggplants, steamed knuckles, stews and dumplings.

Owner:陈杏英

Impurity removal device for water treatment and impurity removal method thereof

InactiveCN112587991AAvoid affecting the effect of filteringIncrease the gapStationary filtering element filtersWater storage tankElectric machine

The invention discloses an impurity removal device for water treatment and an impurity removal method thereof. The impurity removal device for water treatment comprises a water storage tank, an impurity collection and filter tank and an impurity removal mechanism. The impurity collection and filter tank is slidably connected to an inner cavity of the water storage tank in a sleeving mode, and theheight of the impurity collection and filter tank is the same as the vertical height of the inner cavity of the water storage tank. The impurity removal mechanism comprises a rectangular hollow floating frame, a plurality of steel wire ropes, a driving motor and a transmission rod, the rectangular hollow floating frame is slidably connected to an inner cavity of the impurity collection and filtertank in a sleeving mode, the side walls of the periphery of the rectangular hollow floating frame are slidably attached to the side walls of the periphery of the inner cavity of the impurity collection and filter tank correspondingly, a plurality of liquid discharging holes which are uniformly distributed at intervals are formed in the side walls of the periphery of the impurity collection and filter tank, and the inner diameter of each liquid discharging hole is 2 mm. Visible large-size impurities can be conveniently filtered and screened out, the large-size impurities can be conveniently, rapidly and conveniently collected in a centralized mode, and the later-period further processing treatment efficiency is improved.

Owner:万发之

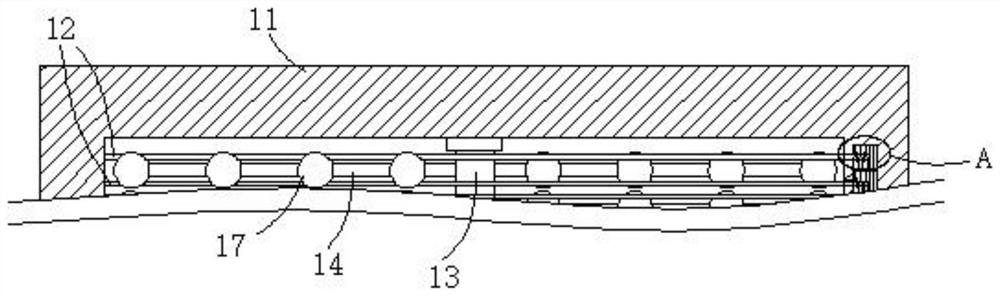

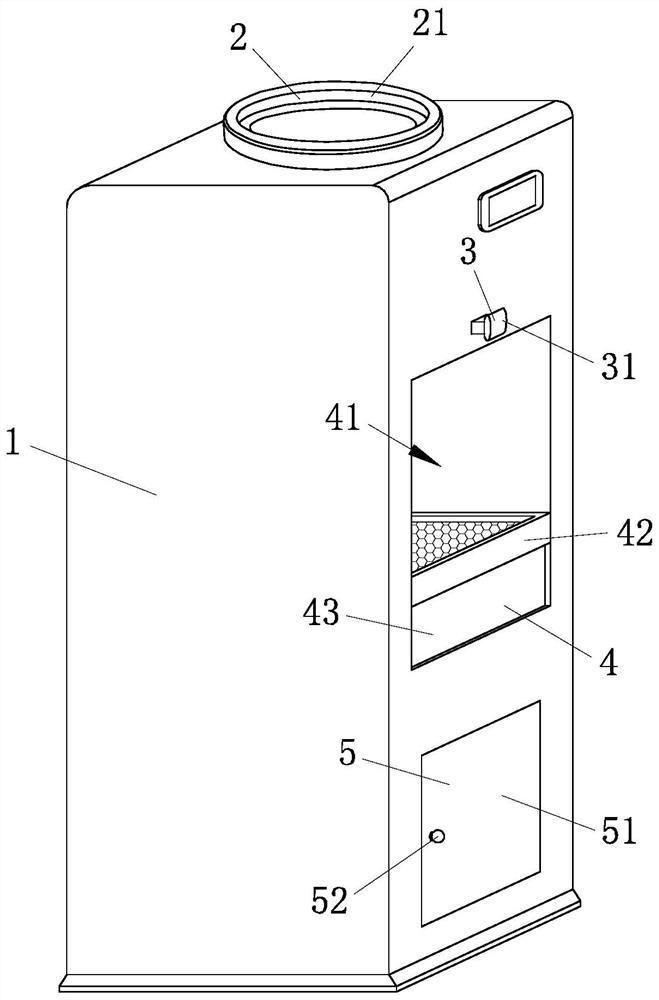

Water dispenser based on Internet of Things

The invention relates to the technical field of water dispensers, in particular to a water dispenser based on the Internet of Things. The water dispenser comprises a water dispenser, a water inlet mechanism, a control mechanism, a placing mechanism, a storage mechanism, a collecting mechanism and a filtering mechanism, an external water bucket can be conveniently and fixedly placed through the water inlet mechanism, impurities can be conveniently filtered, a user can conveniently control and take out drinking water in the water dispenser under the action of the control mechanism, cups can be conveniently placed through installation of the placing mechanism, and meanwhile the cups with different lengths can be conveniently placed; overflowed water, tea leaves and other sundries can be conveniently filtered and discharged under the action of the filtering mechanism and enter the storage box to be stored and collected, overflowed waste water can be conveniently stored and cleaned throughthe collecting mechanism, and meanwhile tea cups can be conveniently placed and stored under the action of the storage mechanism.

Owner:黄雯曼

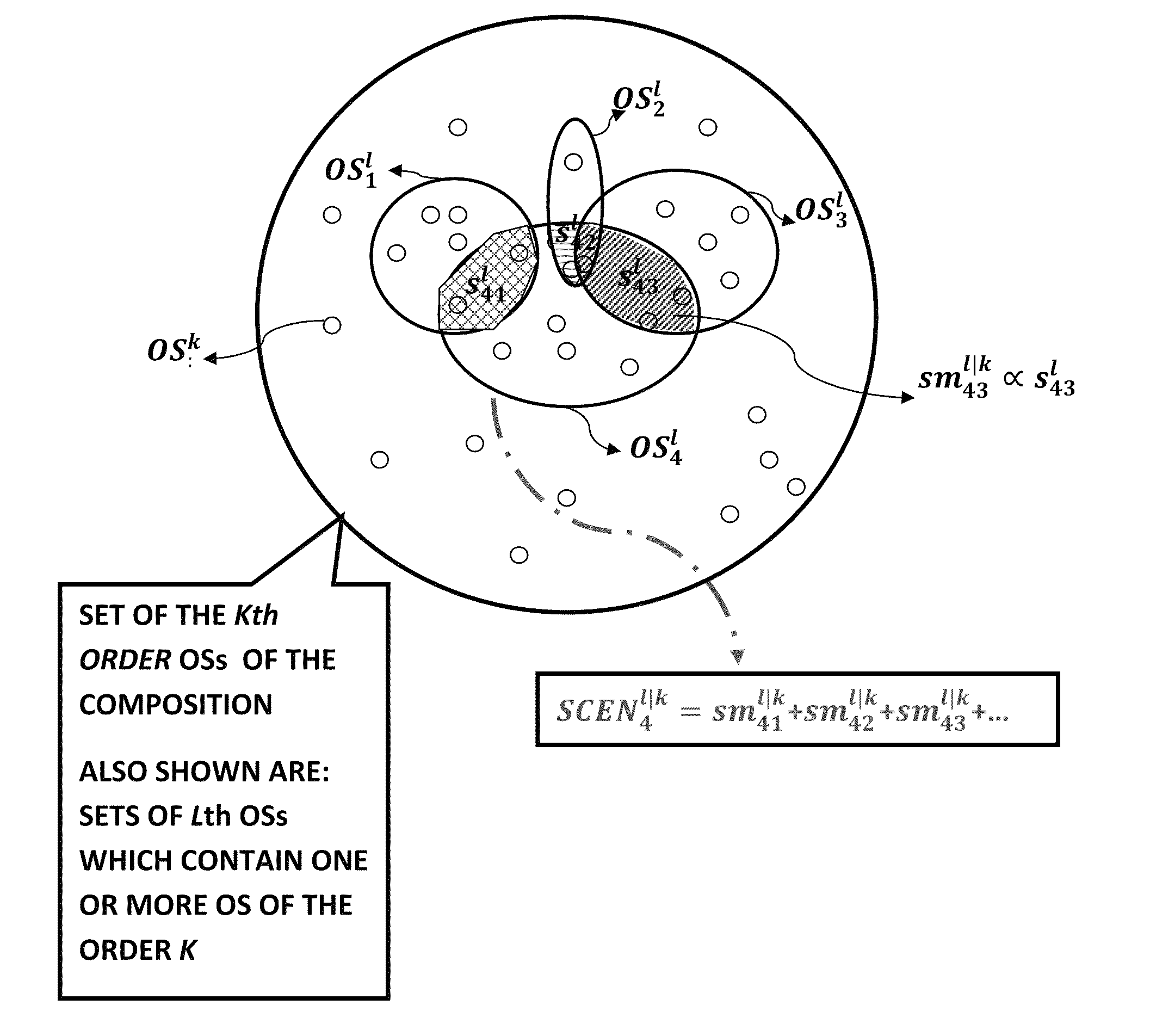

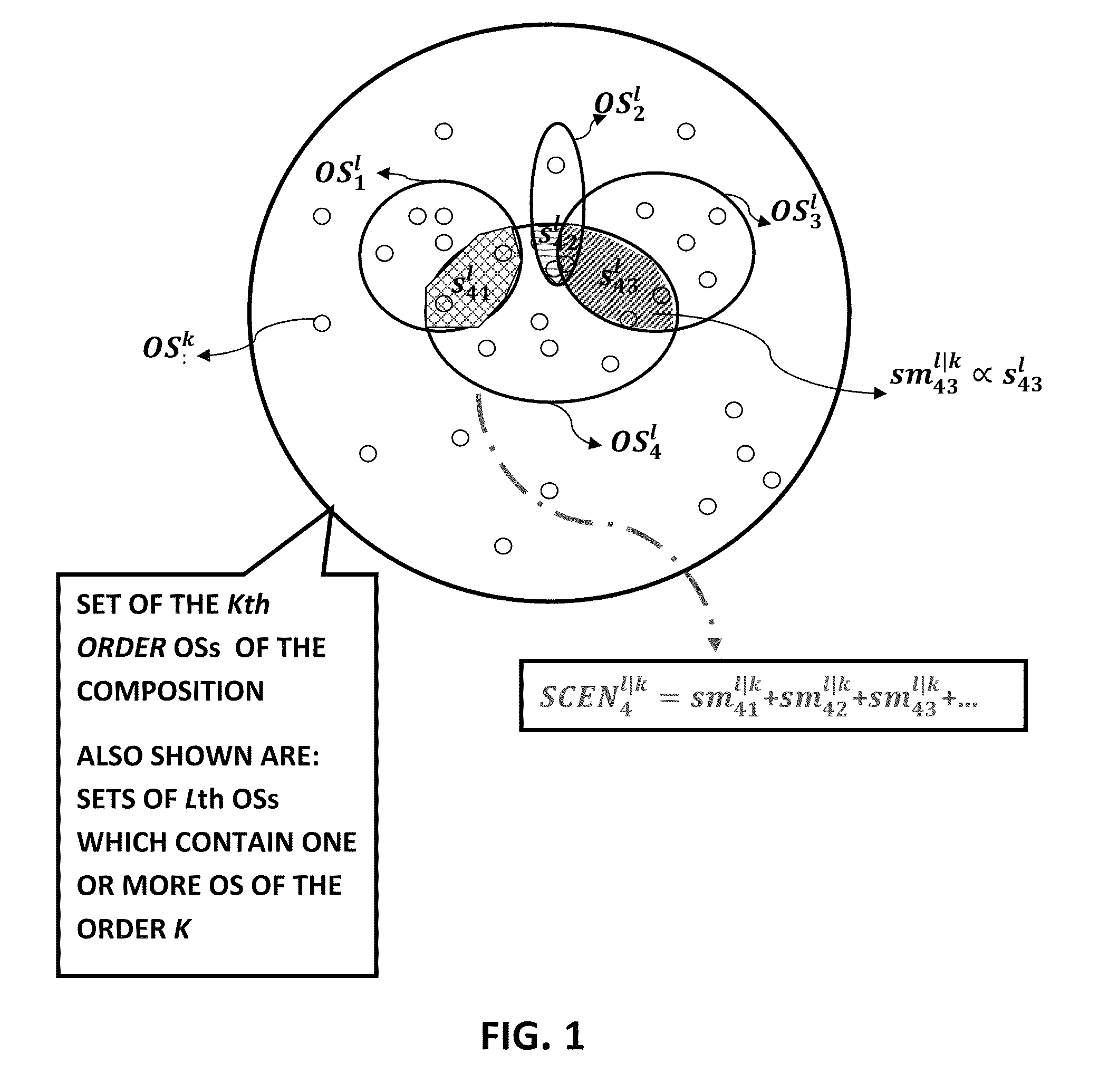

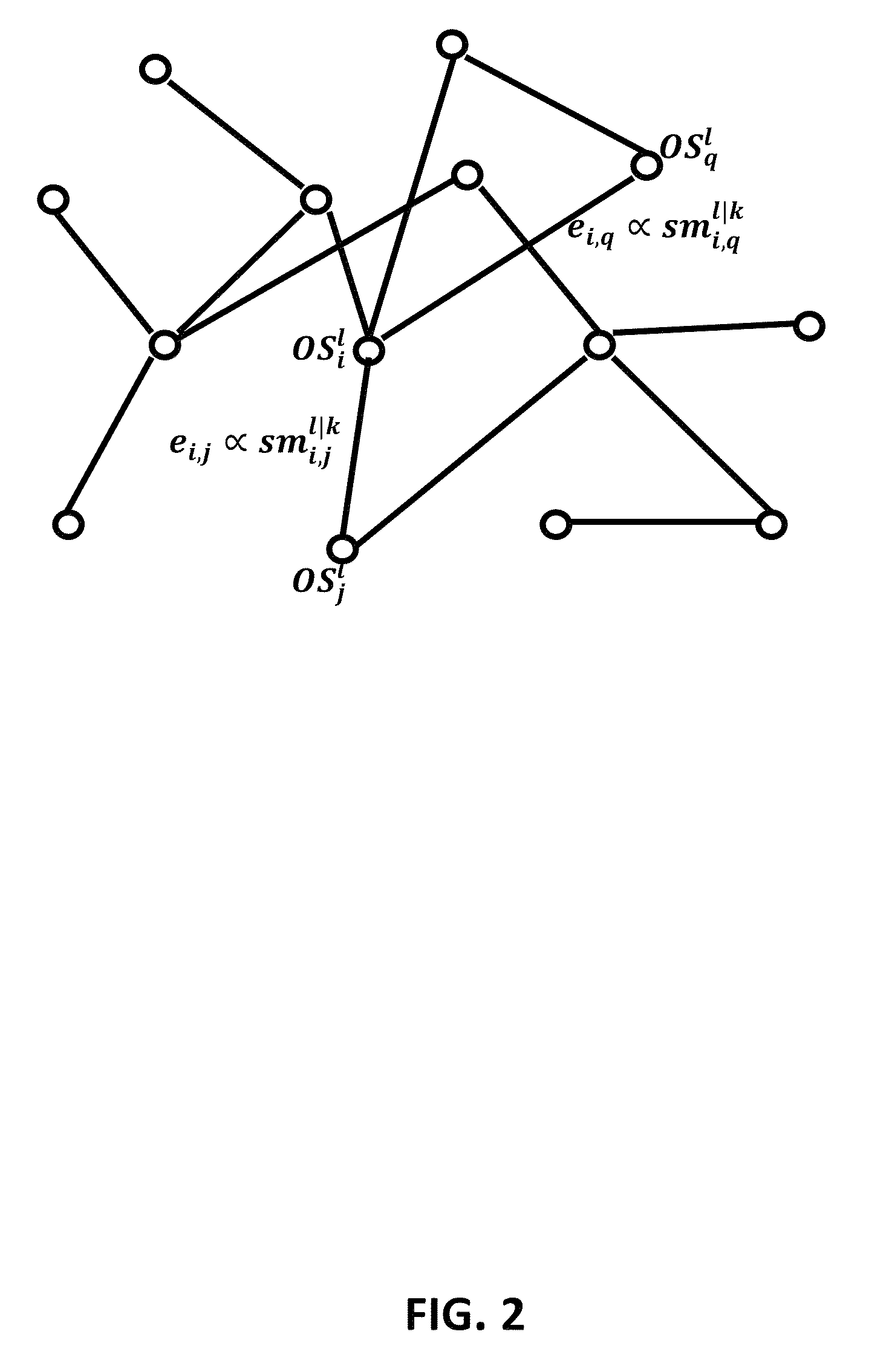

System and method for a unified semantic ranking of compositions of ontological subjects and the applications thereof

ActiveUS8612445B2Fast and efficient scoringHigh similarityDigital data information retrievalSemantic analysisSubject matterRanking

Owner:HATAMI HANZA HAMID

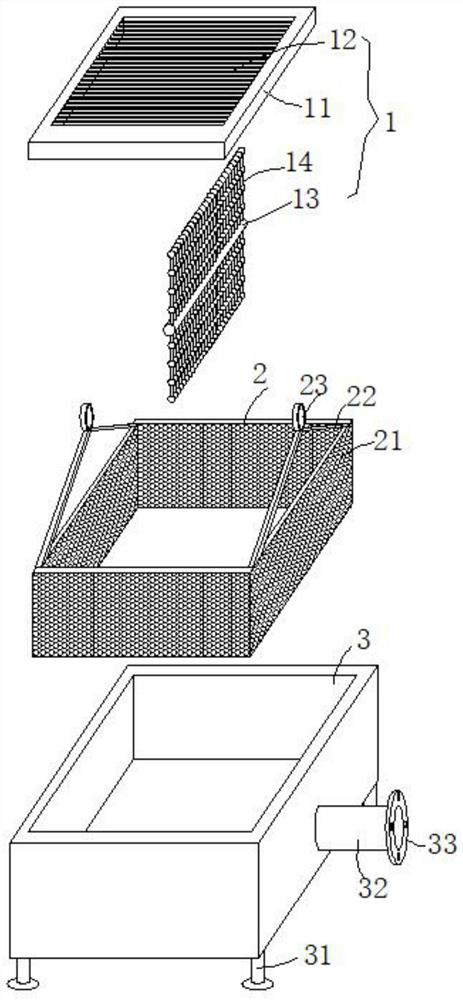

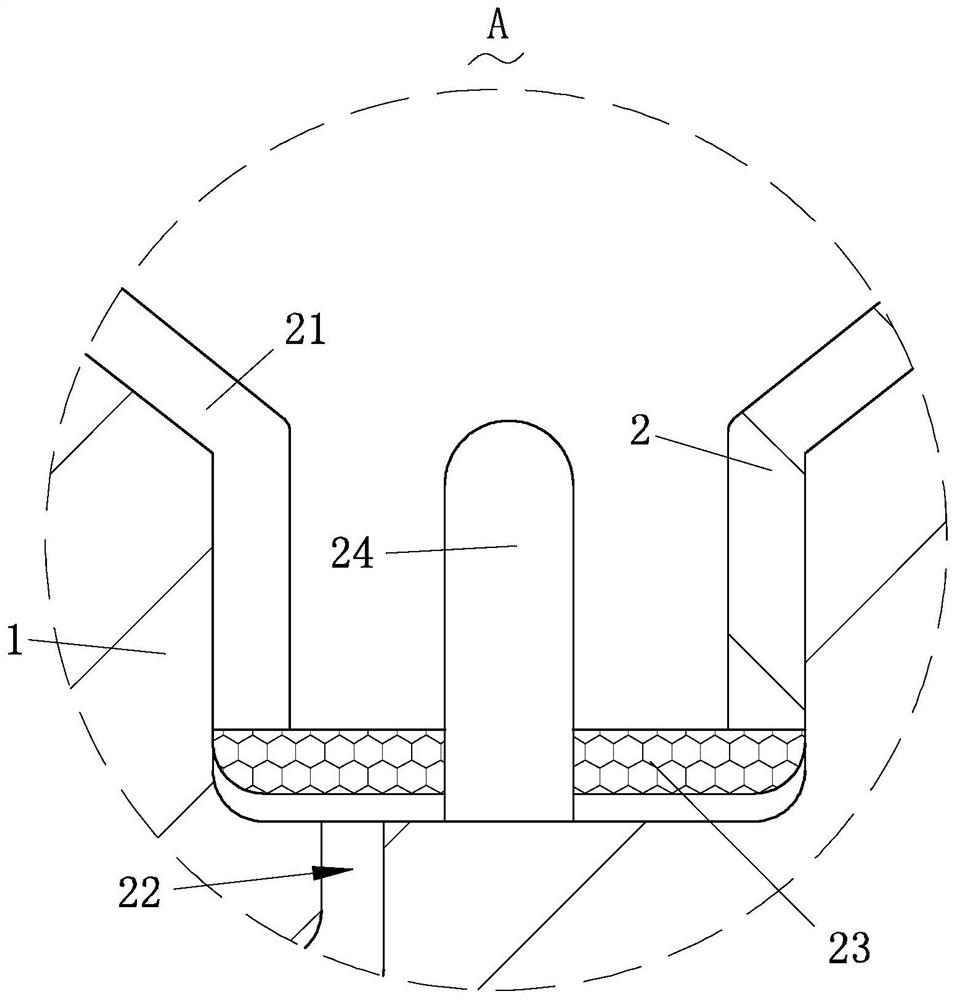

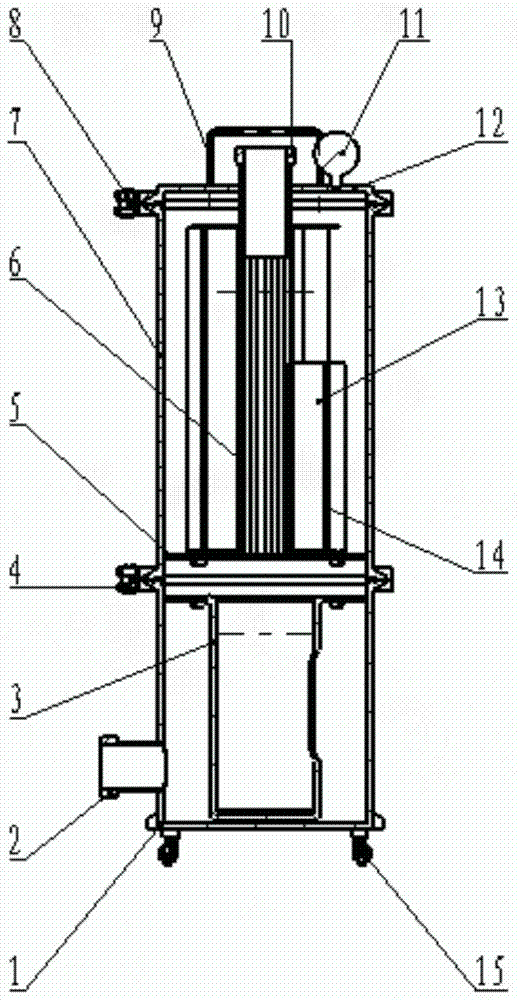

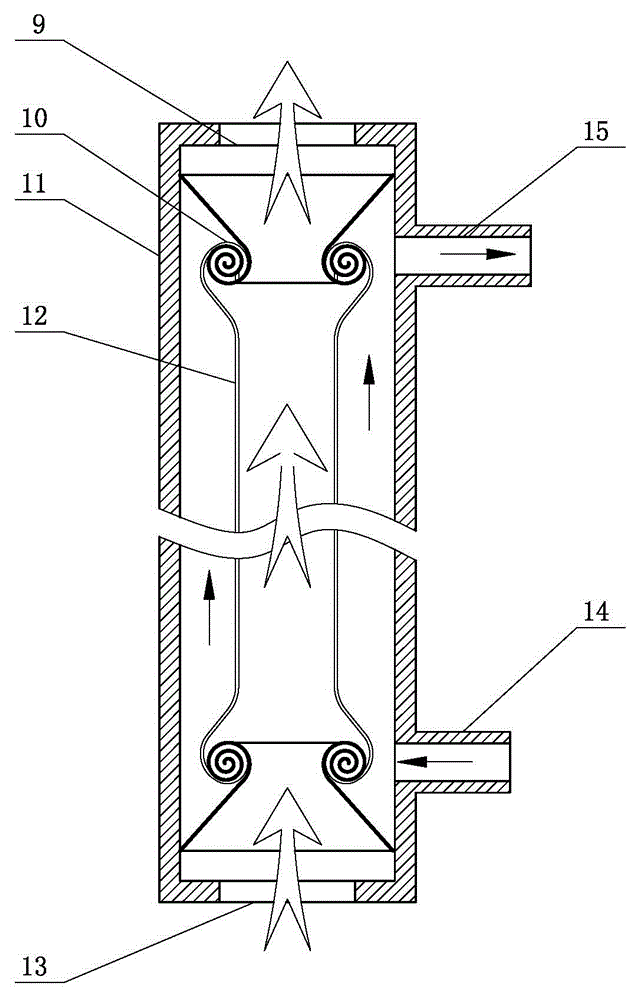

A gas filter device placed in front of vacuum obtaining equipment

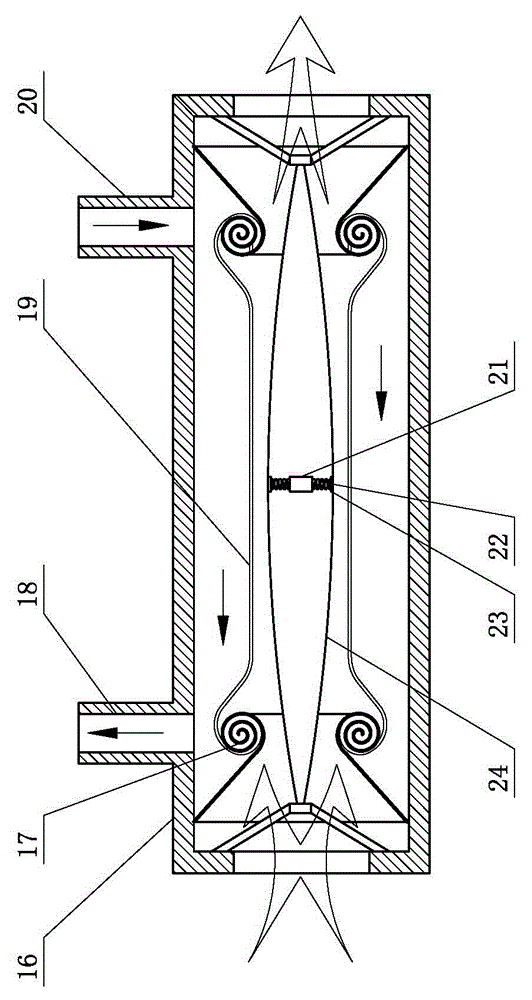

ActiveCN105649959BImprove protectionConducive to keeping the exhaust cleanPositive displacement pump componentsPositive-displacement liquid enginesVacuum pumpingPulp and paper industry

The invention relates to the technical field of vacuum, in particular to a gas filtering device arranged in front of vacuum pumping equipment. The gas filtering device comprises an upper-stage filter, a middle connecting disc and a lower-stage filter. A lower-stage air inlet is formed in the lower end of the lower-stage filter. The upper end of the lower-stage filter is connected with the bottom of the upper-stage filter. An upper-stage air outlet is formed in the top of the upper-stage filter. The middle connecting disc is arranged at the bottom of the upper-stage filter. A plurality of through holes enabling the upper-stage filter to communicate with the lower-stage filter are formed in the middle connecting disc in the circumferential direction. Trundles are arranged at the bottom of the lower-stage filter. The lower-stage air inlet is connected with a pumped air source. The upper-stage air outlet is connected with a vacuum pump. The gas filtering device arranged in front of the vacuum pumping equipment is high in working efficiency, the maintenance interval is long, and the interiors of the filters can be cleaned easily.

Owner:SHENYANG SCI INSTR RES CENT CHINESE ACAD OF SCI

A powder distribution equipment with sub-sieving and filtering functions

ActiveCN113171965BSmooth rotationEasy to adjustSievingScreeningElectric machineryMaterial distribution

The invention relates to a powder distribution equipment with the function of sub-sieving and filtering. The storage mechanism, the central shaft is fixed on the middle top of the base, and the central screen mechanism is arranged outside the middle of the central shaft, the top of the central shaft is fixed with a top plate, and the side end of the top plate is arranged with a side plate beam. The beneficial effect of the present invention is: the powder material distribution equipment with sub-sieving and filtering function can slide and move the storage and disc separation board through the activities of the storage and disc separation board and the lower plate, which is convenient to adjust and use the storage and disc separation board, When the storage and distribution boards are moved out, they can be easily adjusted to the outer side of the body for better material distribution, and the shafts on the top of the storage and distribution boards can be equipped with storage structures, such as storage barrels, etc. The rotation of the plate shaft can conveniently rotate the storage barrel, making it more convenient to control and use.

Owner:无锡诚智炼钢辅助材料有限公司

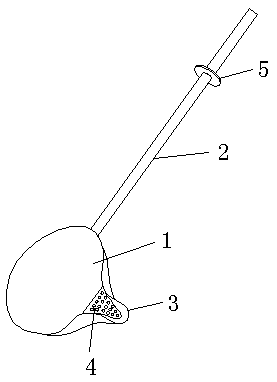

Spoon

The invention discloses a spoon, which comprises a spoon body (1), a connecting rod (2) and a handle, and also includes a filter plate (4) and a U-shaped groove-shaped spoon mouth (3); the side of the spoon body (1) The wall is provided with a gap, the mouth of the spoon (3) is connected with the gap of the body (1) and has a smooth transition, the upper end of the mouth of the spoon (3) and the upper end of the body (1) are on the same plane; the filter plate (4) is arranged on the mouth of the spoon ( 3) in the groove. Since the spoon of the present invention is provided with a spoon mouth (3) and a filter plate (4), it is easy to use and simplifies the operation of making seasoning and scooping soup when people drink soup or eat hot pot.

Owner:霍红英

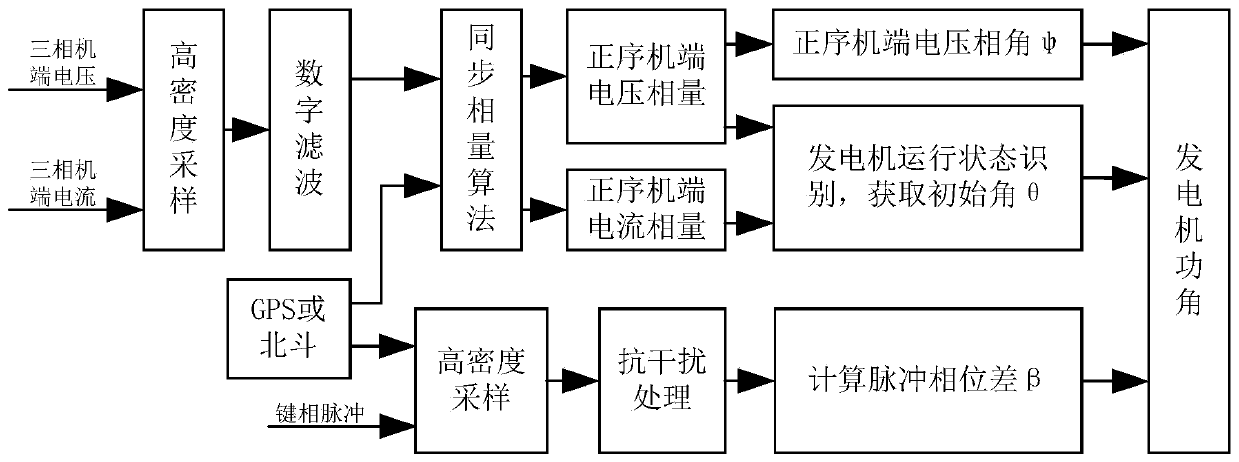

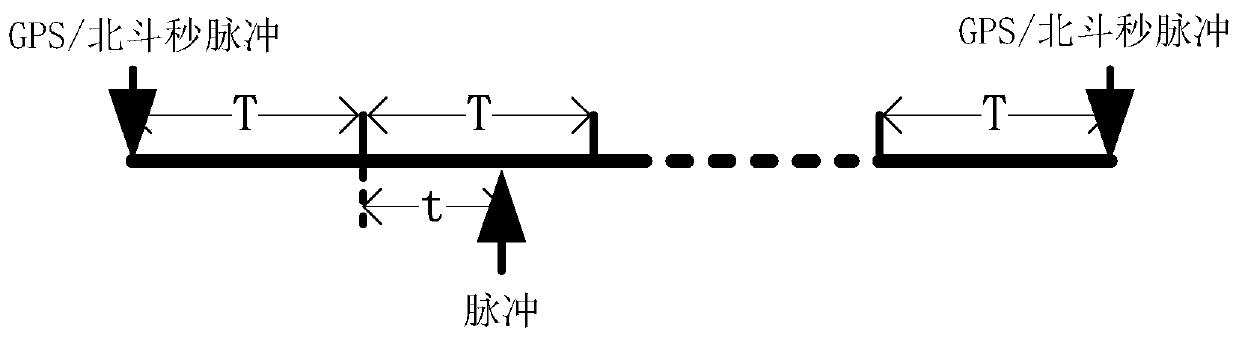

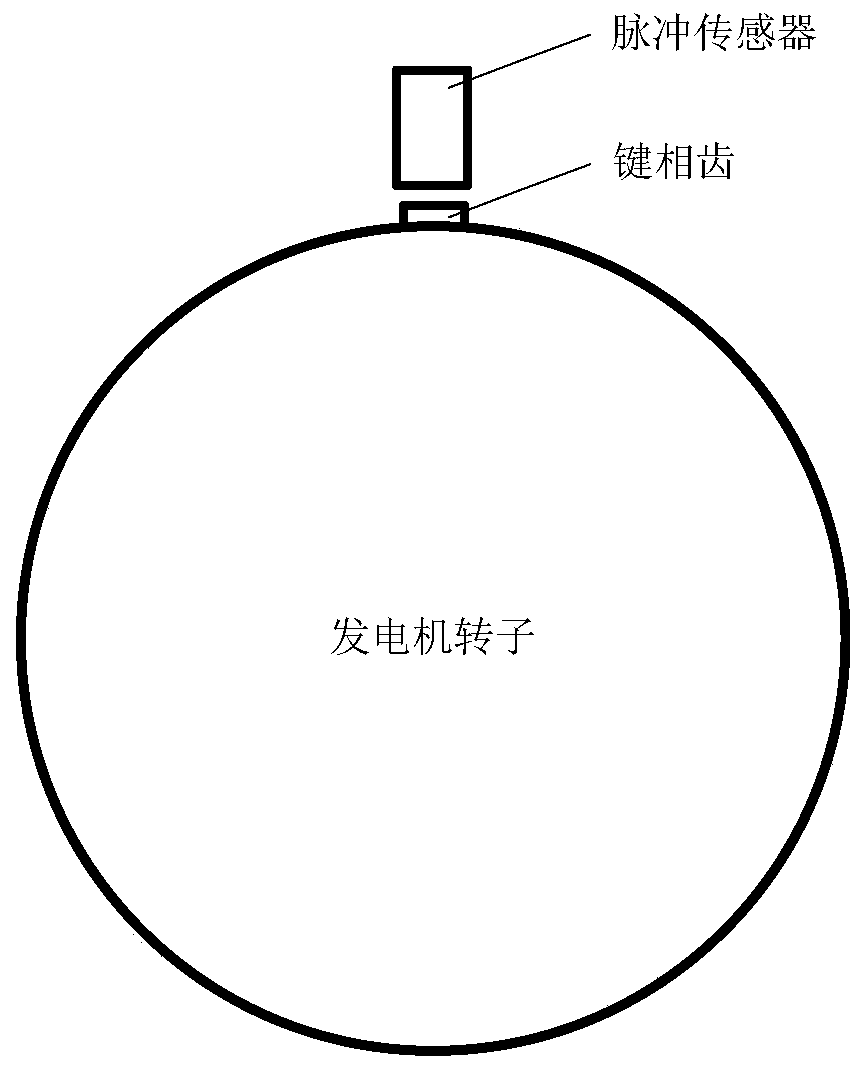

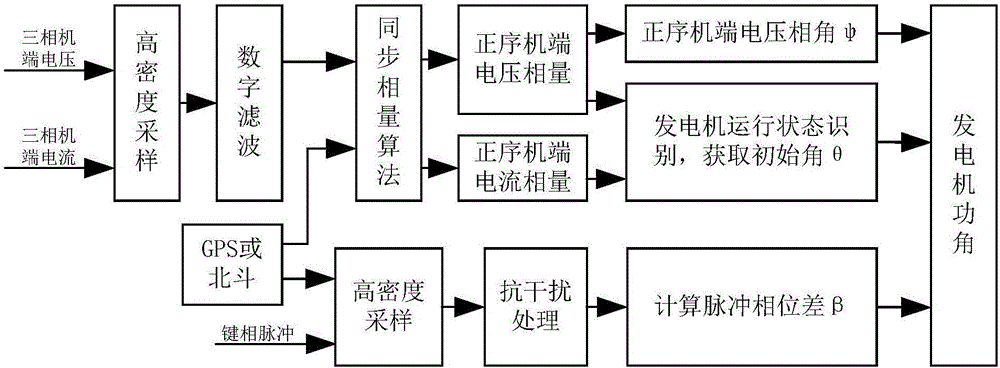

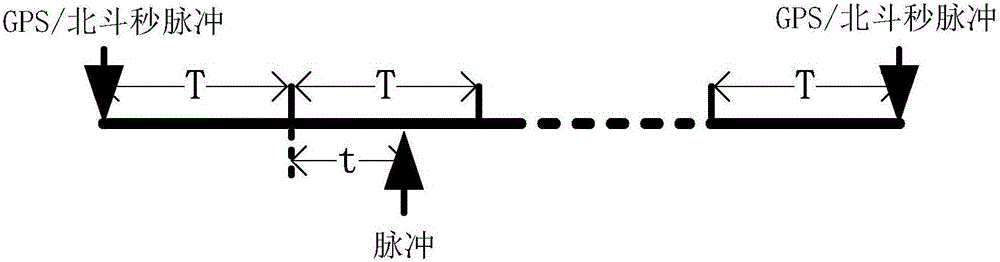

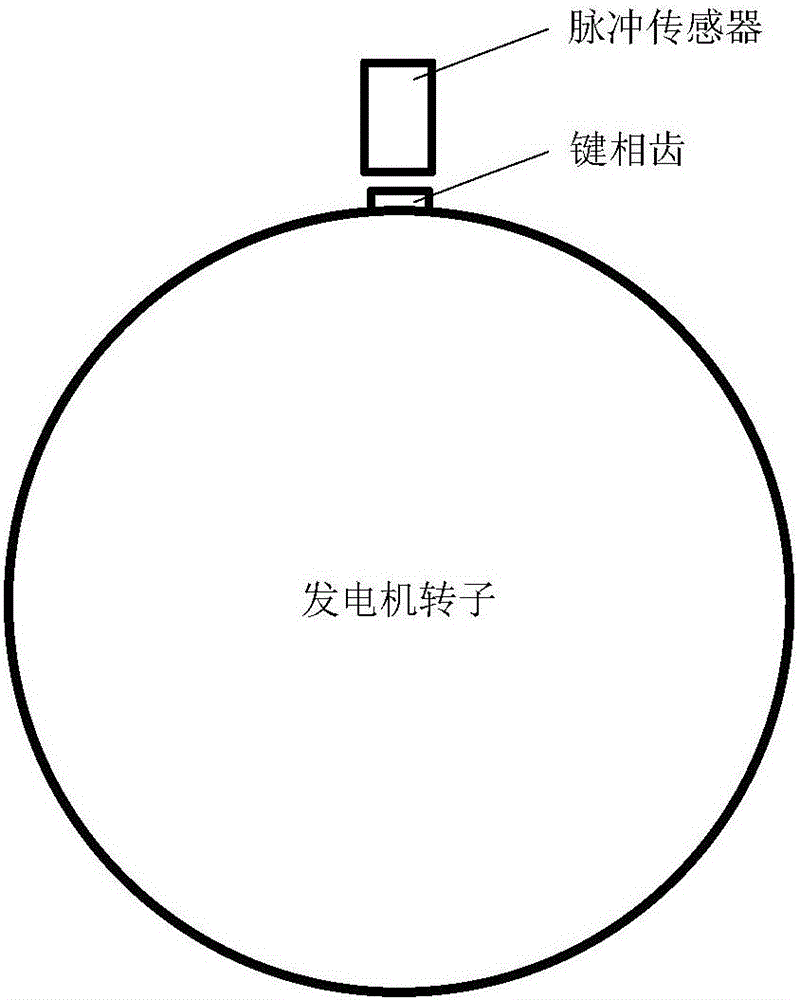

A real-time power angle measurement method for generators

ActiveCN106646229BEasy to filter outImprove accuracyVoltage-current phase angleSystems intergating technologiesInterference resistanceHigh density

The invention discloses a real-time power angle measuring method of a generator. The method takes GPS or Beidou pulse per second as standard, and samples electricity at a generator end and a key pulse impulse signal with high density at equal intervals. Through performing corresponding anti-interference treatment on the collected signal, high-precision synchronous phasor quantity and key phase impulse position information can be acquired, thereby acquiring the high-precision real-time power angle of the generator. The method has the advantages of being easy to perform anti-interference treatment on the signal; the method is strong in diversified impulse signal adaptation and high in power angle measuring precision.

Owner:BEIJING SIFANG JIBAO AUTOMATION

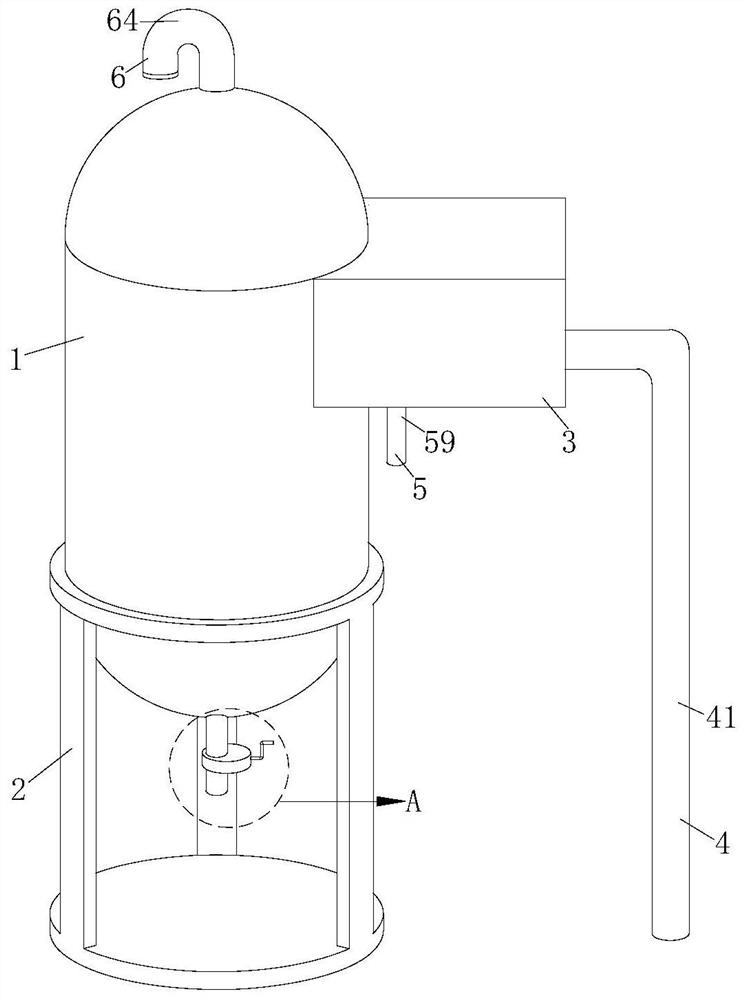

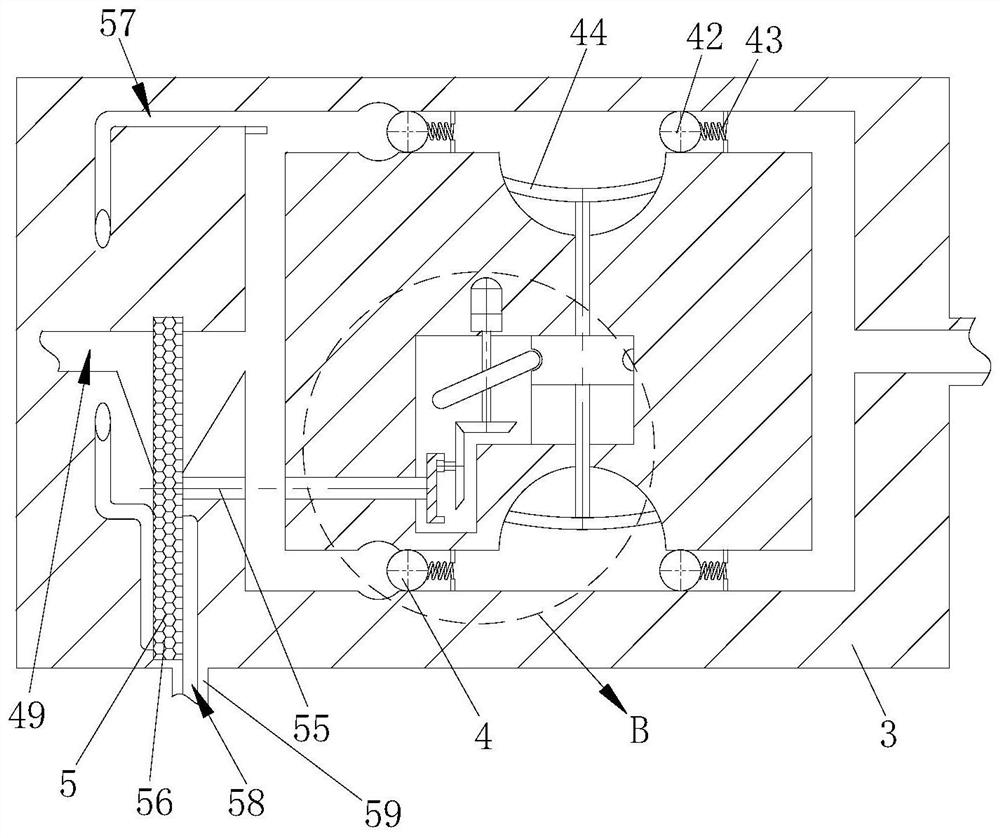

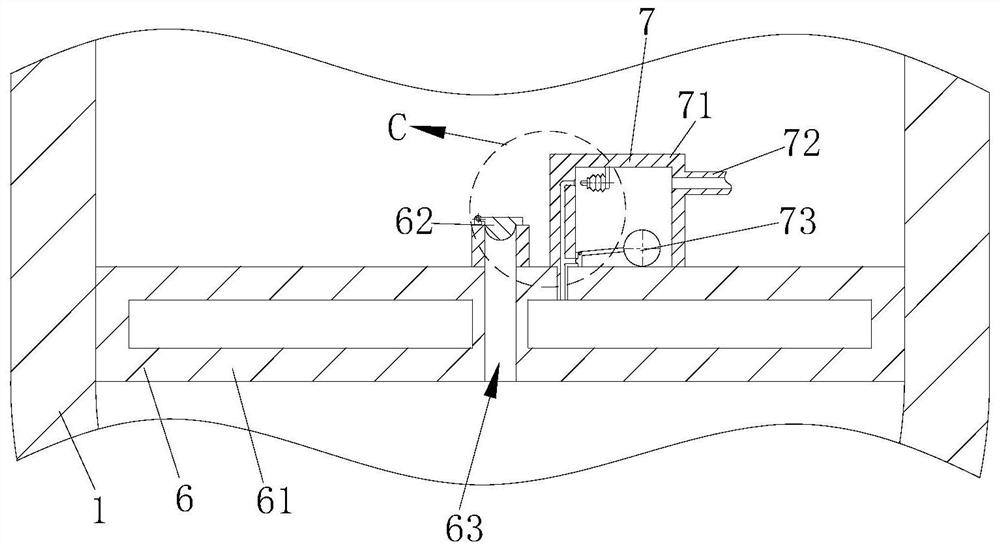

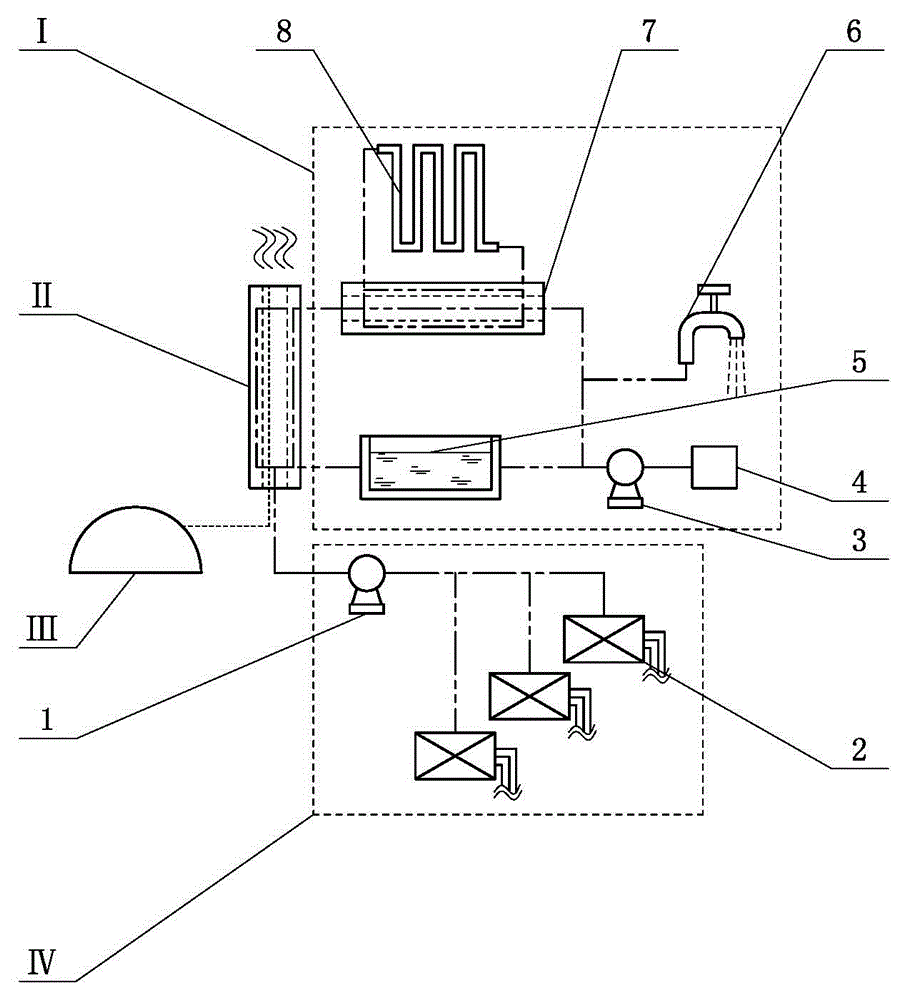

Energy-saving environment-friendly high-purity bamboo vinegar producing and collecting system

InactiveCN105112280AImprove cooling effectEfficient reuseVinegar preparationThermal energyWater flow

The invention discloses an energy-saving environment-friendly high-purity bamboo vinegar producing and collecting system, belongs to the field of bamboo vinegar producing equipment, and particularly relates to a high-purity bamboo vinegar producing and collecting and heat energy recycling device. The energy-saving environment-friendly high-purity bamboo vinegar producing and collecting system is characterized by comprising a kiln, a condensing device, a bamboo vinegar collecting device and a heat recycling device; the condensing device comprises a condenser, the condenser comprises a heat-insulation outer sleeve and a film inner sleeve, a circulating water flowing space is formed between the heat-insulation outer sleeve and the film inner sleeve, and a smoke condensing space is inwardly enclosed by the film inner sleeve; the kiln is connected with a smoke inlet via a smoke exhaust pipe; the bamboo vinegar collecting device is arranged below a position along the smoke inlet. The energy-saving environment-friendly high-purity bamboo vinegar producing and collecting system has the advantages that high-quality bamboo vinegar liquid can be efficiently recycled, settled and separated, and heat generated in production procedures can be sufficiently recycled.

Owner:ZIBO DACHUANG AUTOMATIC TECH CO LTD

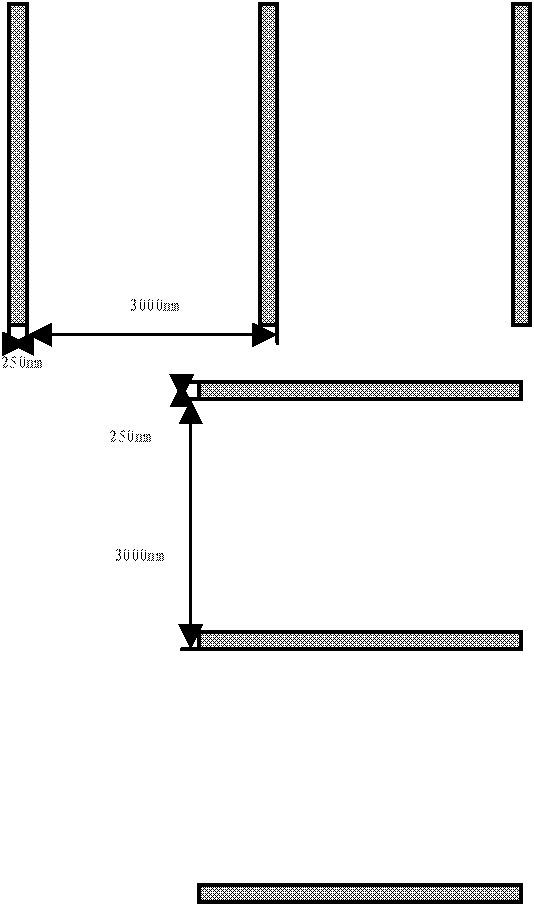

Method for evaluating and filtering noise of space images of photoetching machine

ActiveCN102221789AAvoid inconsistenciesImage center deviation is smallPhotomechanical exposure apparatusMicrolithography exposure apparatusPrincipal component analysisWave aberration

The invention relates to a method for evaluating and filtering the noise of space images of a photoetching machine, comprising the following steps of: acquiring the space images of tested marks; establishing the standard difference of the noise of the space images and the ideal light intensity of the space images; carrying out analysis of main components on the standard difference of the noise of the space images; and utilizing the best smooth factor to carry out two-dimensional sample band smooth filtering on the space images and obtaining the space images in which noise is filtered. In the method, the noise of the space image is simply and conveniently filtered, and the solving accuracy and the solving repeatability based on solving wave aberration of the space image are improved.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

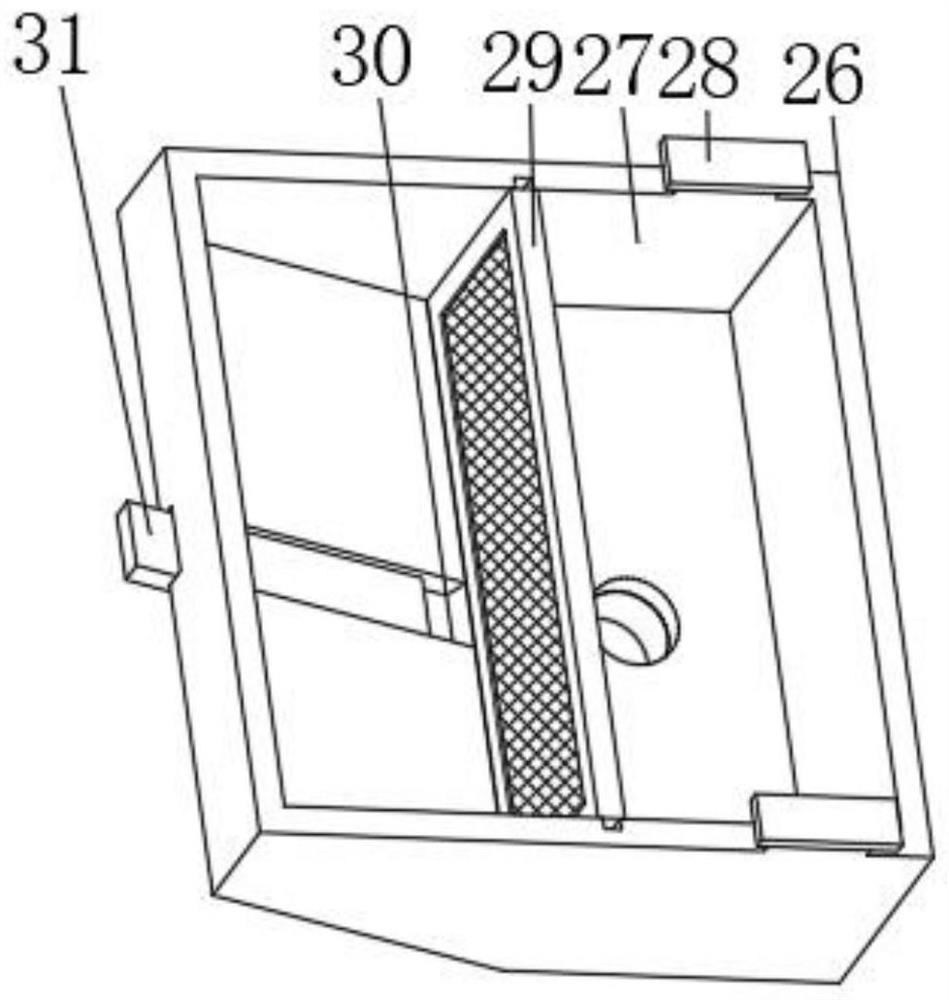

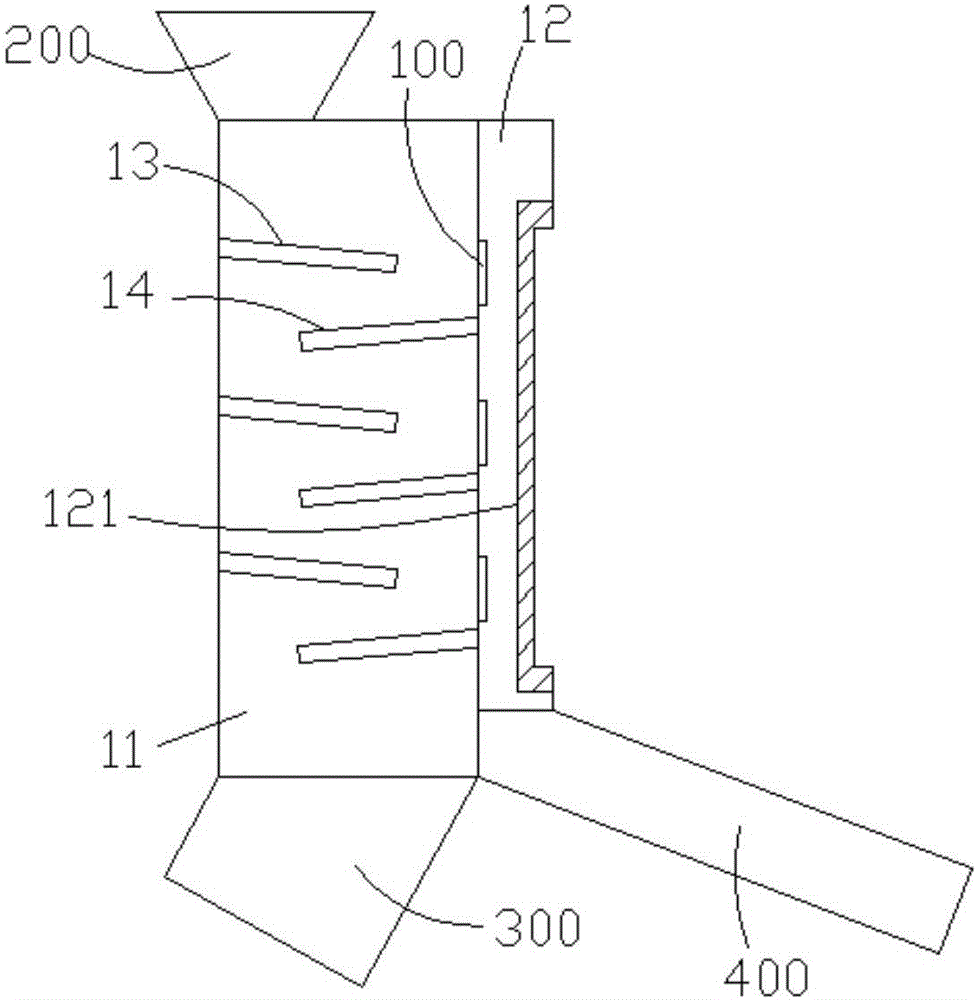

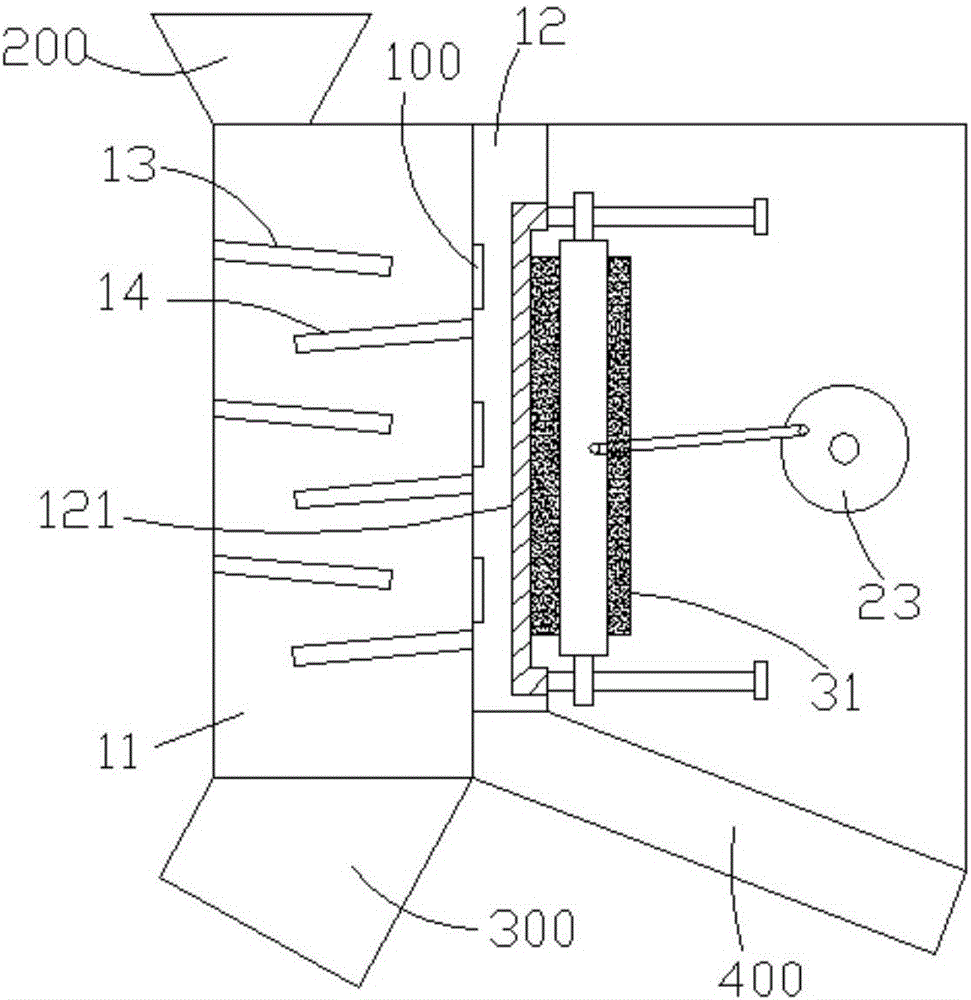

Feeding unit in iron removal device

InactiveCN107520043AIncrease the itineraryEasy to filter outMagnetic separationEngineeringIron removal

The invention discloses a feeding unit in an iron removal device. The feeding unit comprises a feeding shell, an iron discharge shell, a plurality of first feeding plates and a plurality of second feeding plates. The first feeding plates and the second feeding plates are layered, are downwardly obliquely fixed into an inner cavity of the feeding shell and are staggered with one another, iron outlets are formed in a side wall of the feeding shell, and each iron outlet is particularly formed in a position above the corresponding second feeding plate; the iron discharge shell is fixed onto the outer wall of the feeding shell, and an inner cavity of the iron discharge shell is communicated with the iron outlets. The feeding unit has the advantages that material movement stroke can be increased by the first feeding plates and the second feeding plates, and accordingly iron can be conveniently sufficiently filtered out.

Owner:ZHENJIANG YUANDA TRANSMISSION MACHINERY

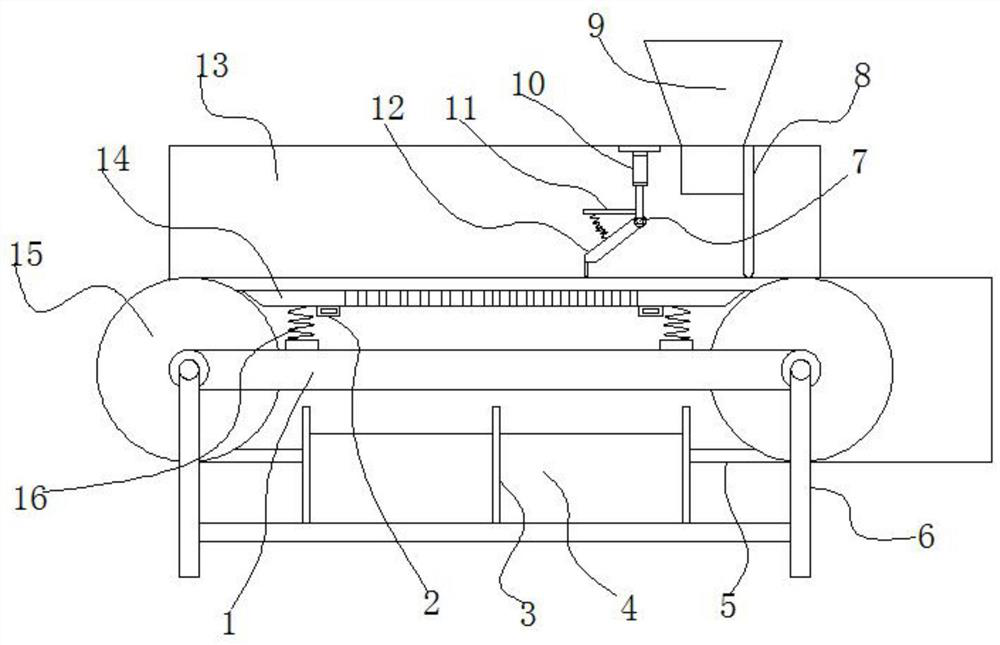

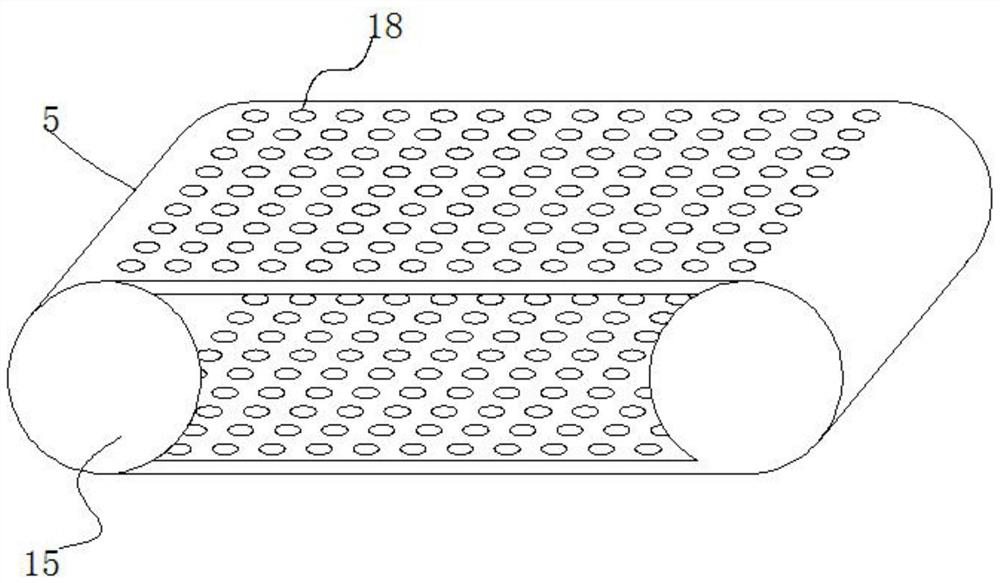

Shrimp tail size separation device

InactiveCN112352821AEasy to filter outAvoid low screening efficiencyShellfish/bivalves grading/classificationElectric machineryShrimp

The invention relates to the technical field of shrimp tail processing, and discloses a shrimp tail size separation device, which comprises a frame, wherein conveying rollers are horizontally, longitudinally and fixedly installed on the left portion and the right portion of the frame, the two conveying rollers are in transmission connection through a conveying belt, a plurality of through openingsdistributed at equal intervals are formed in the conveying belt, and brackets are fixedly mounted at four corners of the frame in a vertically downward manner. According to the invention, shrimp tails are injected into the conveying belt through the injection hopper, and are evenly distributed on the through opening of the conveying belt through the dispersing rake in the conveying process of theconveying belt, the two vibration motors located at the bottom of the material screening plate work to drive the material screening plate to vibrate materials, the shrimp tails located on the conveying belt pass through the two sets of screening holes with different hole diameters in the screening plate to screen small shrimp tails and then screen large shrimp tails, the screened shrimp tails areclassified and separated through areas on the two sides of the partition plate on the flow guide groove plate, and screening in the whole process is quite convenient.

Owner:顺祥食品有限公司

Real-time power angle measuring method of generator

ActiveCN106646229AEasy to filter outImprove accuracyVoltage-current phase angleSystems intergating technologiesElectricityHigh density

The invention discloses a real-time power angle measuring method of a generator. The method takes GPS or Beidou pulse per second as standard, and samples electricity at a generator end and a key pulse impulse signal with high density at equal intervals. Through performing corresponding anti-interference treatment on the collected signal, high-precision synchronous phasor quantity and key phase impulse position information can be acquired, thereby acquiring the high-precision real-time power angle of the generator. The method has the advantages of being easy to perform anti-interference treatment on the signal; the method is strong in diversified impulse signal adaptation and high in power angle measuring precision.

Owner:BEIJING SIFANG JIBAO AUTOMATION

A low-concentration flue gas desulfurization method for hydropower silicon smelting

ActiveCN109482048BReduce emission concentrationReduce generationDispersed particle separationParticulatesSorbent

Owner:云南永昌硅业股份有限公司

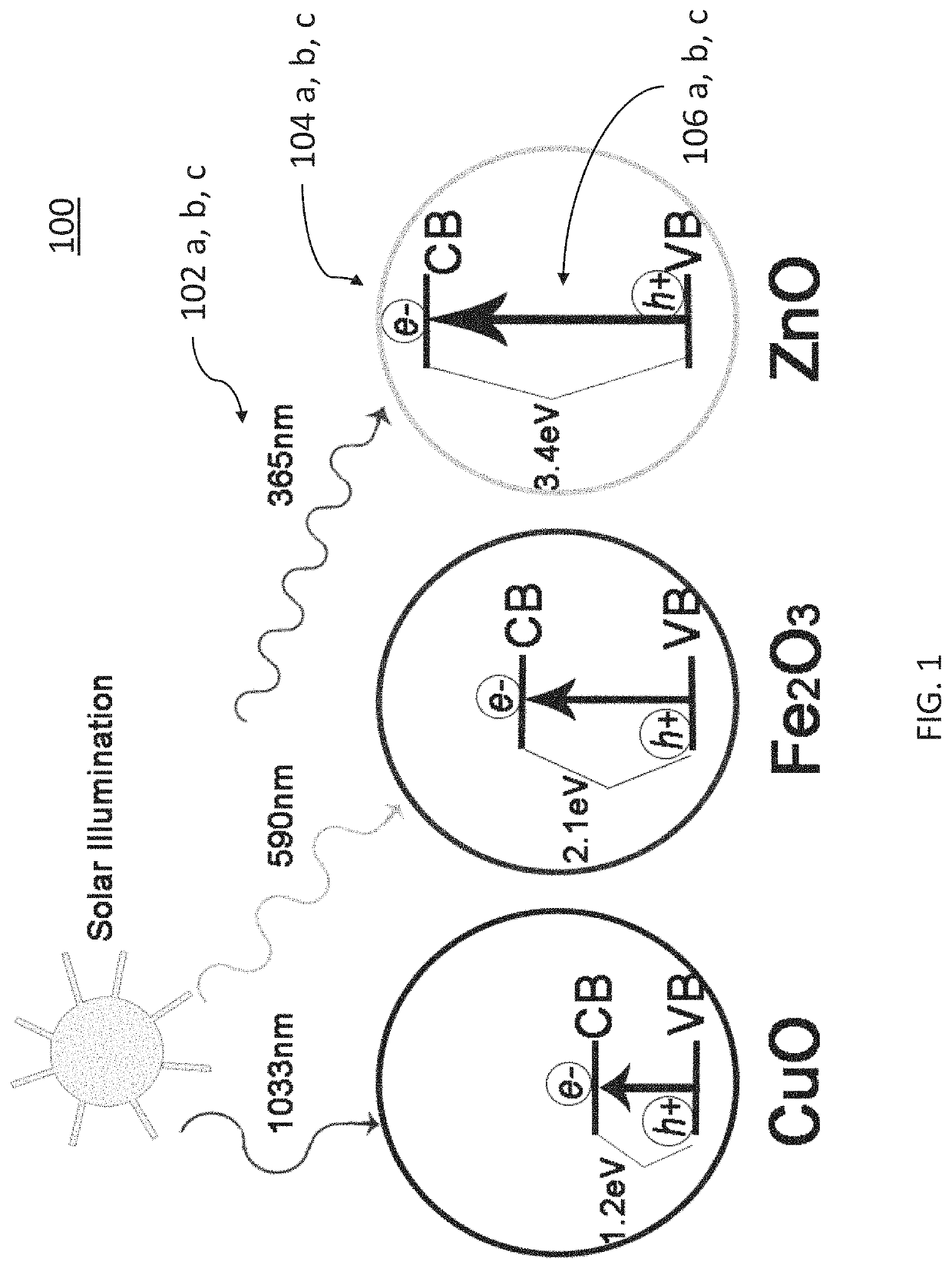

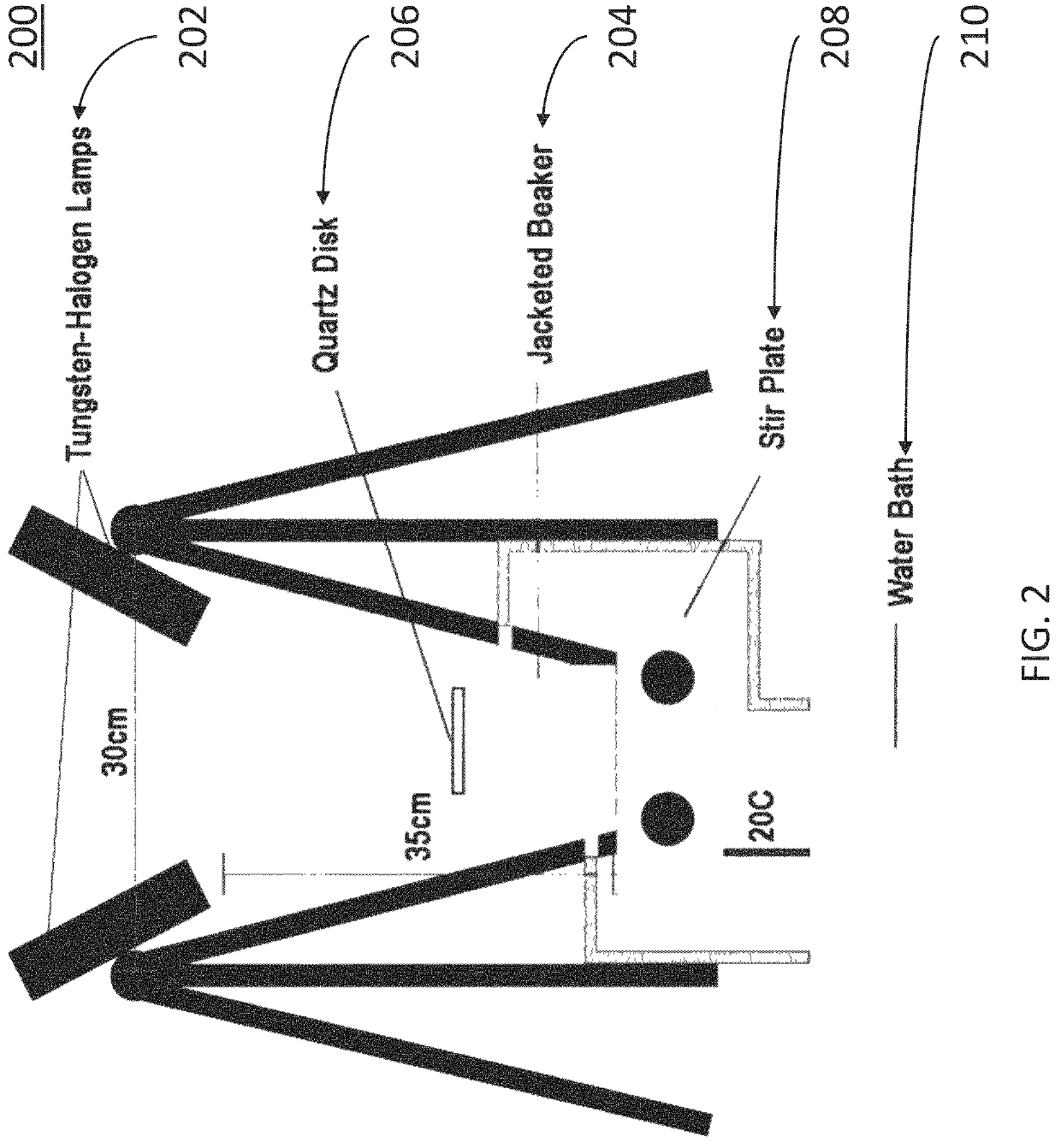

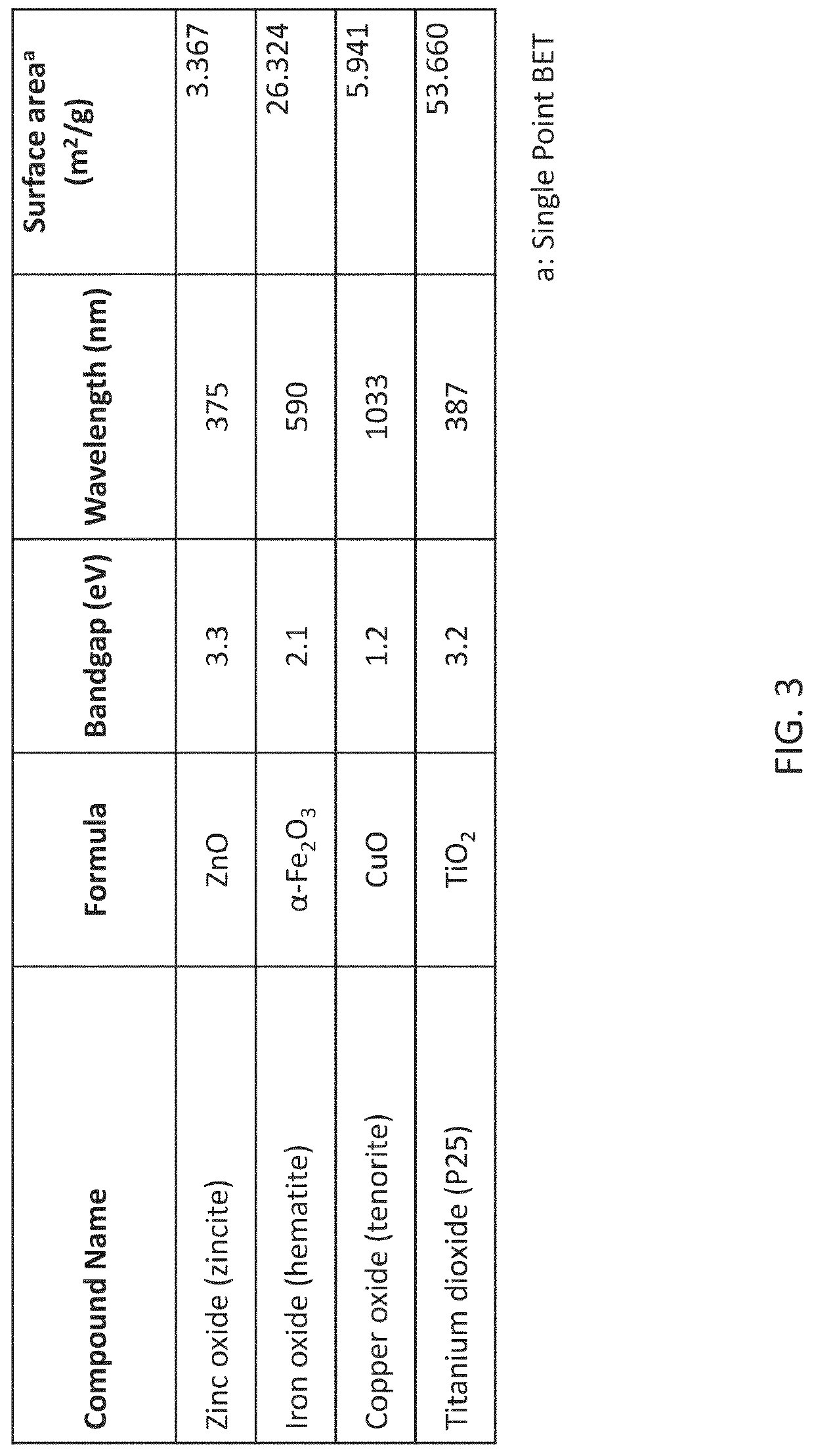

Multi-spectral photocatalytic compounds

ActiveUS11298689B2Efficient degradationEasy to filter outGas treatmentWater/sewage treatment by irradiationCopper oxideNear infrared spectra

Disclosed are various combinations of three different metal-oxide photocatalysts with three different bandgaps that can be used to harvest multiple wavelengths of incident solar radiation and to thus efficiently degrade recalcitrant contaminants. The photocatalysts are from the class of transition metal oxides and are non-toxic compounds based on earth-abundant materials. In some embodiments, particles of the photocatalysts are formed to be greater in diameter than about 0.1 μm in order to make them easier to filter out after treating the contaminant. In some embodiments, the metal-oxide photocatalysts are zinc oxide which is ultraviolet active, hematite which is active in the visible spectrum, and copper oxide which is active in the near infrared spectrum. Various combinations in various embodiments achieve measured contaminant degradation rates greater than the sum of the degradation rates of the individual photocatalysts that make up the combination.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Method for evaluating and filtering noise of space images of photoetching machine

ActiveCN102221789BAvoid inconsistenciesImage center deviation is smallPhotomechanical exposure apparatusMicrolithography exposure apparatusPrincipal component analysisWave aberration

The invention relates to a method for evaluating and filtering the noise of space images of a photoetching machine, comprising the following steps of: acquiring the space images of tested marks; establishing the standard difference of the noise of the space images and the ideal light intensity of the space images; carrying out analysis of main components on the standard difference of the noise ofthe space images; and utilizing the best smooth factor to carry out two-dimensional sample band smooth filtering on the space images and obtaining the space images in which noise is filtered. In the method, the noise of the space image is simply and conveniently filtered, and the solving accuracy and the solving repeatability based on solving wave aberration of the space image are improved.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Additive used for methanol gasoline circulation sieving, and preparation method thereof

InactiveCN110105989AFast adsorptionLow costLiquid carbonaceous fuelsFuel additivesPropanolActive agent

The invention discloses an additive used for methanol gasoline circulation sieving, and a preparation method thereof. The adsorbent is prepared from, by weight, 70 to 90 parts of aluminum chloride hexahydrate, 20 to 25 parts of water, 2 to 8 parts of ethanol, 2 to 3 parts of propanol, 2 to 5 parts of titanium dioxide, 3 to 8 parts of an active agent, 1 to 5 parts of a binder, 6 to 12 parts of a flame retardant and 2 to 4 parts of a reducing agent. The adsorption speed is fast; the additive is capable of absorbing impurities in methanol gasoline rapidly; adding of the binder is capable of realizing caking of impurities in methanol gasoline bond into large particles, so that it is convenient for filtering sieving; the preparation method is simple; operation is convenient; production efficiency is high; the adopted various raw materials are easily available, and cheap; and enterprise cost is reduced.

Owner:CRPC INNOVATION ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com