Impurity removal device for water treatment and impurity removal method thereof

A technology for water treatment and impurities, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of inconvenient centralized collection of large-volume impurities, affecting processing, and inconvenience of impurity removal devices for rapid impurity removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

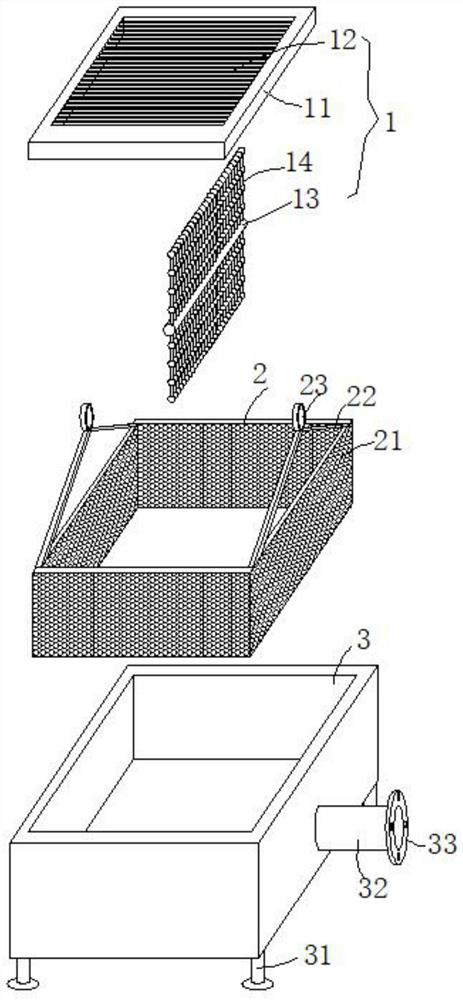

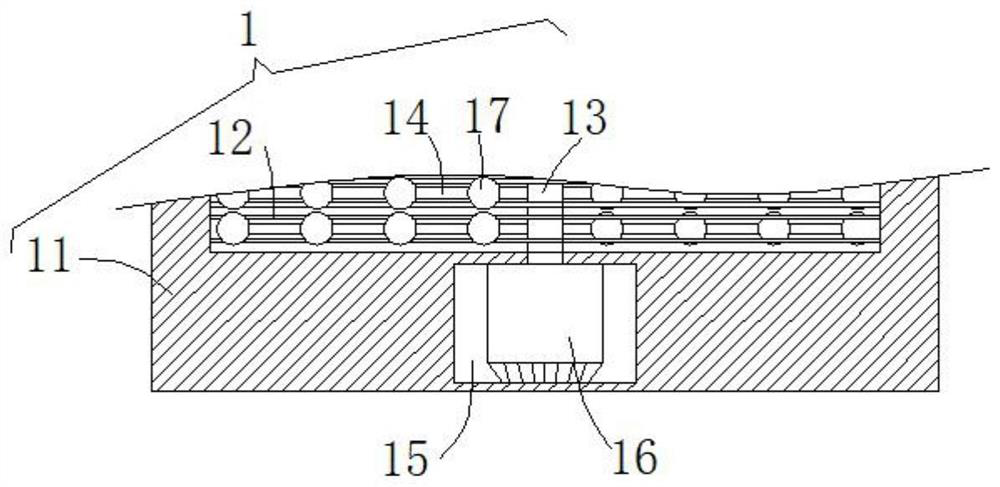

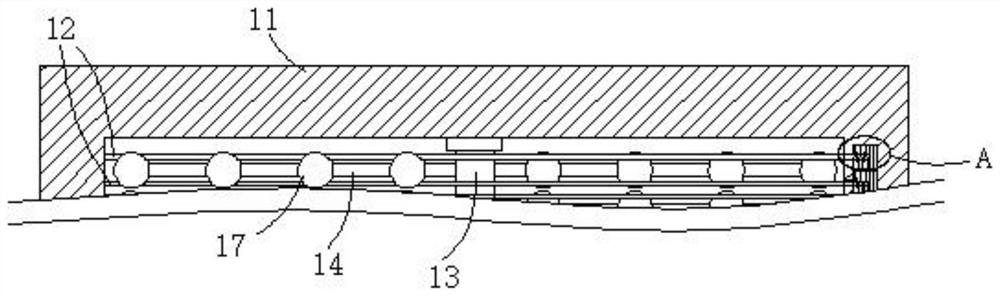

[0027] see Figure 1-4 , the present embodiment provides an impurity removal device for water treatment and an impurity removal method thereof, including a water storage tank 3, a sundries collection filter box 2 and an impurity removal mechanism 1, and the sundry collection filter box 2 is slidably sleeved on the water storage tank 3 and the height of the debris collection filter box 2 is the same as the vertical height of the inner cavity of the water storage tank 3 to prevent the debris collection filter box 2 from protruding from the top opening of the inner cavity of the water storage tank 3. The debris removal mechanism 1 includes a rectangular The hollow floating frame 11, a number of wire ropes 12, the driving motor 16 and the transmission rod 13, the rectangular hollow floating frame 11 is slidably connected to the inner cavity of the debris collection filter box 2, and the surrounding side walls of the rectangular hollow floating frame 11 are respectively connected wi...

Embodiment 2

[0037] see Figure 1-4 , made further improvements on the basis of Example 1:

[0038] The four corners of the bottom end surface of the water storage tank 3 are vertically provided with supporting feet 31 , and the entire water storage tank 3 is supported by the supporting feet 31 .

[0039] The top left and right sides of the debris collection filter box 2 are provided with inverted V-shaped hoisting frames 22, and stainless steel hoisting rings 23 are welded to the top central positions of the two inverted V-shaped hoisting frames 22. The stainless steel hoisting ring 23 at the top center of the inverted V-shaped hoisting frame 22 is connected, so that the debris collection filter box 2 can be hoisted along the inner cavity of the water storage tank 3, so as to facilitate the collection of debris in the debris collection filter box 2. Particles are dumped and cleaned up.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com