Wood block equidistant automatic cutting machine for wood processing

A cutting machine and wood block technology, which is used in wood processing appliances, manufacturing tools, sawing components, etc., can solve problems such as manual pushing of wood blocks, uneven cutting of wood boards, and difficulty in cleaning wood chips, and achieve the effect of improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

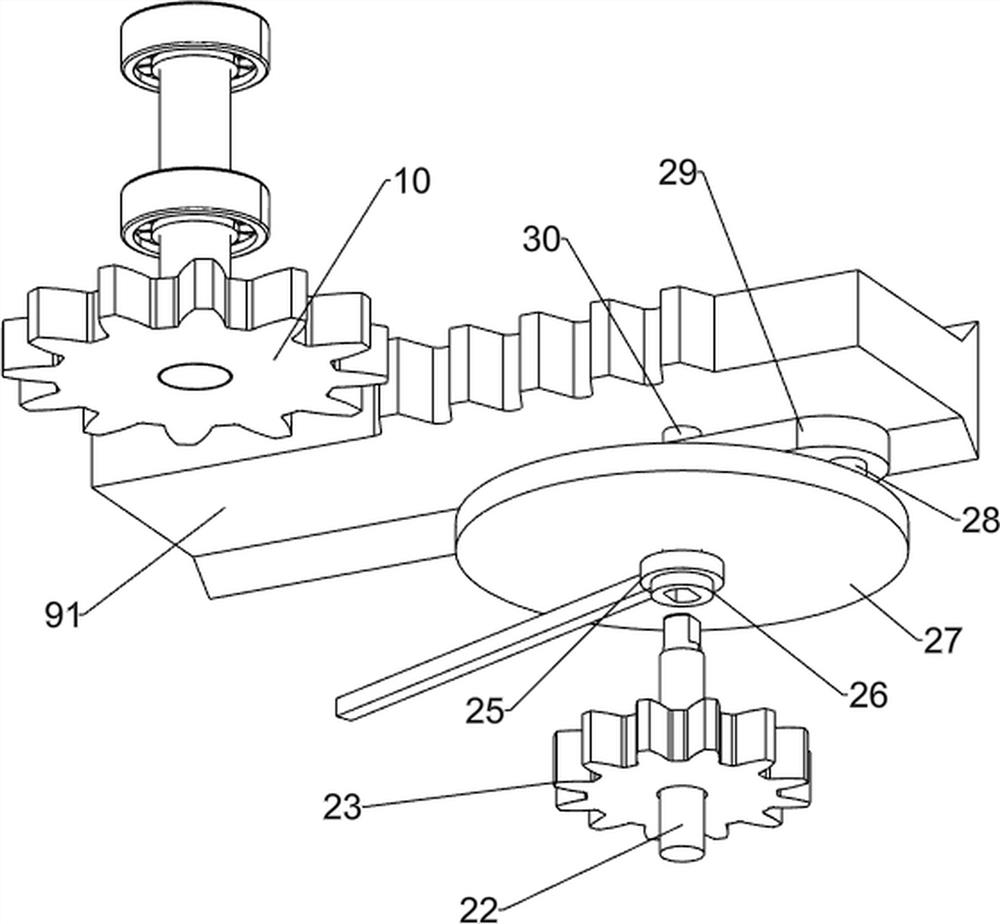

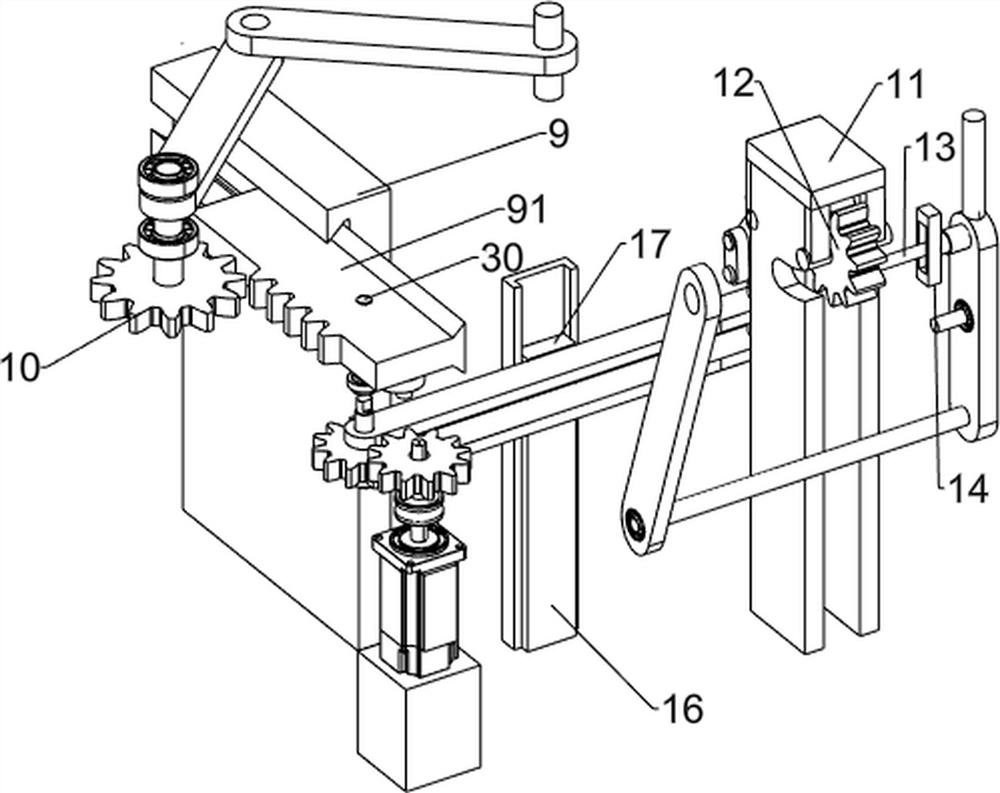

[0025] Isometric automatic cutting machine for wood blocks for woodworking such as Figure 1-Figure 5 As shown, it includes a housing 1, a supporting column 2, a cutting motor 3, a moving mechanism 4 and a pushing mechanism 5. The left side of the inner bottom of the housing 1 is fixedly connected with the supporting column 2, and the top of the supporting column 2 is equipped with a cutting motor 3. A moving mechanism 4 is arranged between the left upper part of the body 1, and a pushing mechanism 5 is arranged on the right side of the housing 1.

[0026] When people need to use this machine, first people place the wooden block on the moving mechanism 4, then start the cutting motor 3 and the pushing mechanism 5, and then people can make the moving mechanism 4 parts move back and forth, and the moving mechanism 4 parts drive the wooden block back and forth Move, when the wooden block moves forward and contacts with the cutting motor 3, the cutting motor 3 cuts the wooden bloc...

Embodiment 2

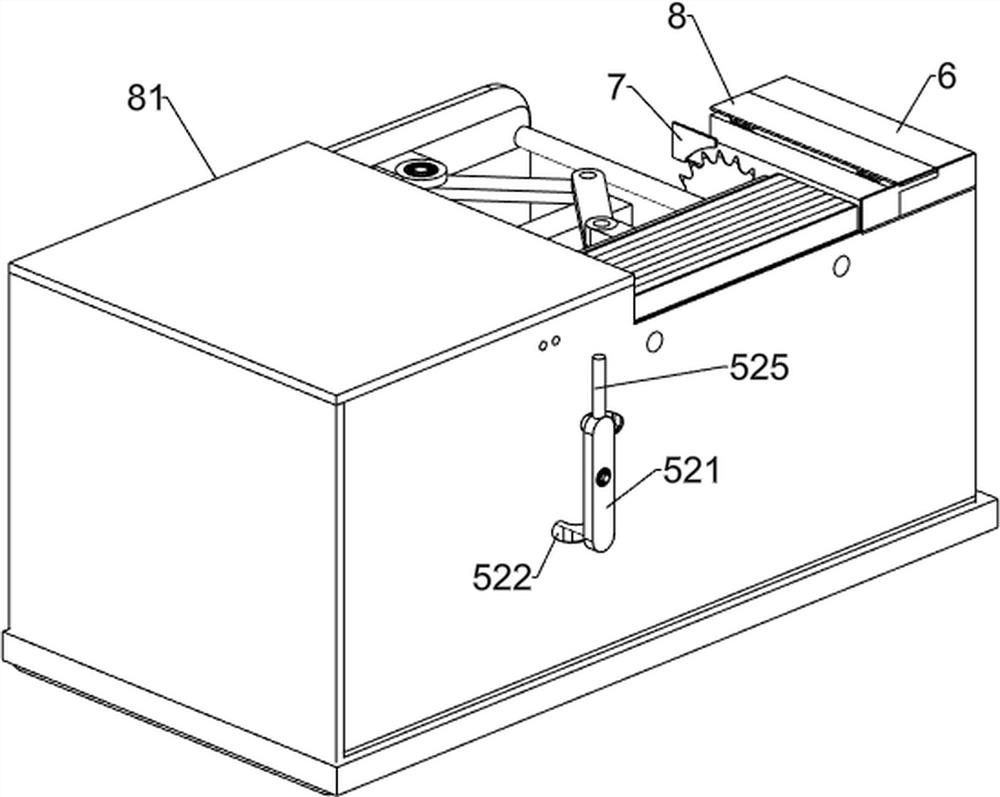

[0032] On the basis of Example 1, such as Figure 5-Figure 8 As shown, it also includes a mounting plate 6, a first fixing plate 7, a protective plate 8 and a cover 81, the top of the left side of the housing 1 is fixedly connected with the mounting plate 6, and the right side of the mounting plate 6 is provided with the first fixing plate 7. A protective plate 8 is arranged on the plate 6 in a rotating manner, and the protective plate 8 cooperates with the first fixing plate 7 , and a cover 81 is provided on the top of the right side of the housing 1 .

[0033] When people need to use the device, the protective plate 8 can be rotated to the right, so that the protective plate 8 is in contact with the first fixed plate 7, thereby preventing the hand from contacting the cutting motor 3, and the cutting motor 3 cuts the wood block. The cut wood blocks fall on the mounting plate 6, which is convenient for people to collect. Wherein, the cover 81 can block the parts below it, ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com