Digital intelligent laying method and system for composite material

A composite material and laying technology, applied in the field of digital intelligent laying of composite materials, can solve the problems of poor generalization ability of process parameter relationship model, immature ultrasonic vibration assisted processing, affecting surface quality, etc., so as to reduce model learning and deployment. cost, improve the efficiency of imitation learning, and improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

[0069] An embodiment of the present invention provides a composite material digital intelligent laying method, including the following steps,

[0070] Step 1, set the laying path;

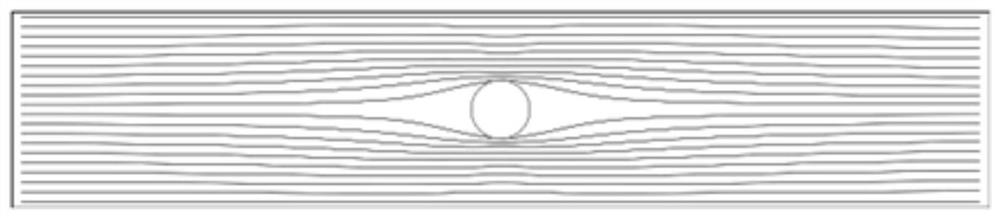

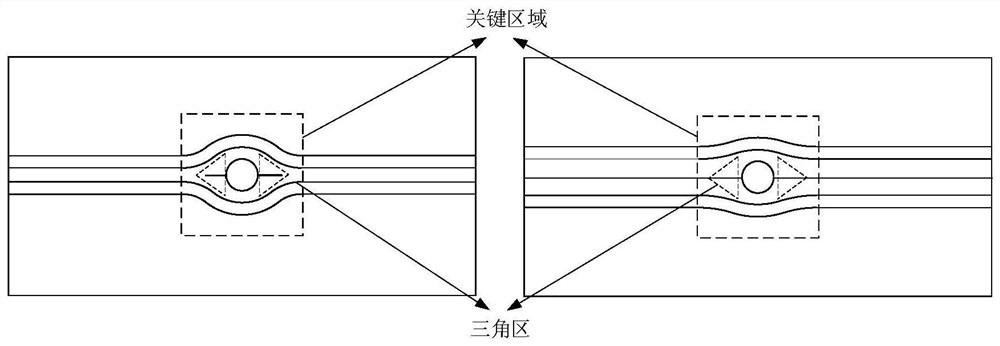

[0071] The embodiment further proposes that if the formed component is a hole-containing part, its laying path is planned according to the forming method of the porous composite structural part, otherwise, the laying path is given according to the conventional path planning method;

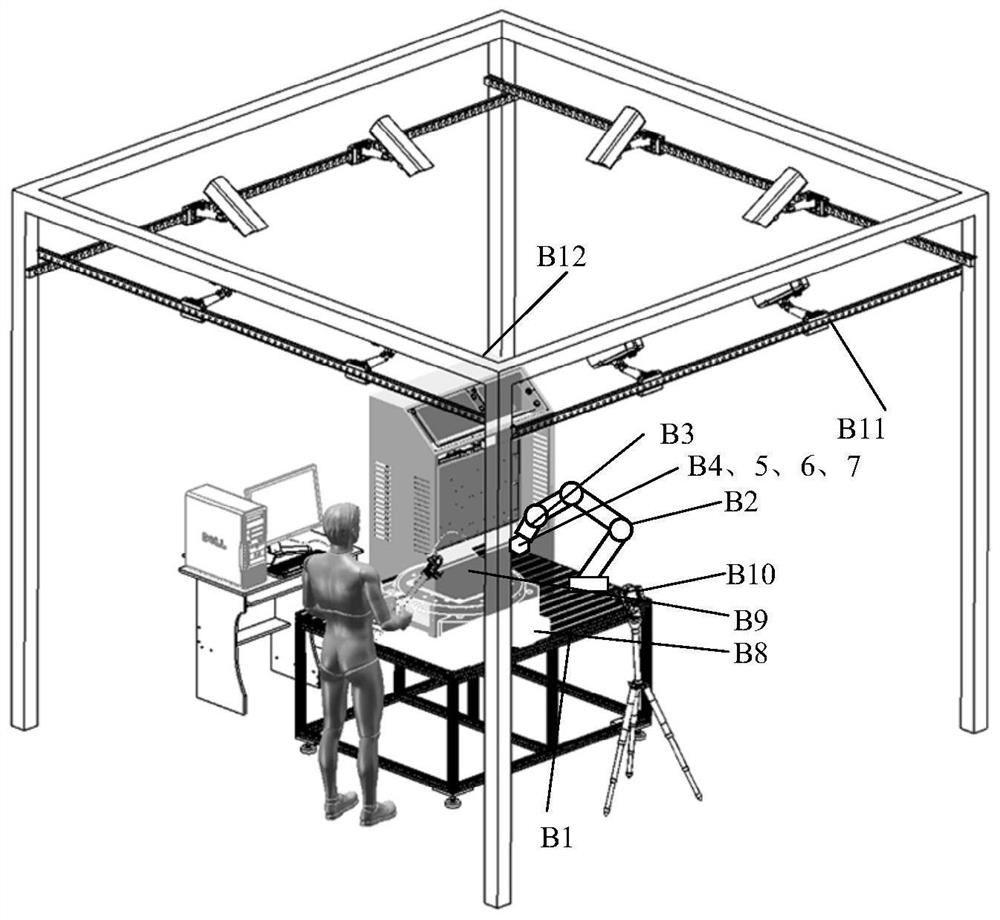

[0072] Step 2, build a fiber laying process parameter model based on imitation learning, and obtain the process parameters under the actual laying path according to the laying path and the surface shape of the formed component;

[0073] The embodiment proposes a method for constructing a fiber laying process parameter model based on imitation learning, combining t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com