Glass fiber bulk yarn preparation method

A technology of glass fiber yarn and glass fiber, which is applied in the field of preparation of glass fiber bulky yarn, which can solve the problems of decreased performance index of inorganic fiber bulky yarn, unfavorable application in the field of environmental protection and dust removal, and many fiber monofilament breakages, etc., to achieve fiber breakage less, high retention rate of strength, uniform yarn bulking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The invention provides a kind of preparation method of glass fiber bulked yarn, comprises the following steps:

[0017] Feed more than two glass fiber yarns into the bulked yarn machine at the same time, and spray them continuously with high-pressure air to make the fibers in a bulky state, and then perform tension adjustment, yarn guiding and winding in sequence to obtain the glass fiber bulk in the package yarn; the monofilament diameter of the bulked glass fiber yarn is 4-6 μm;

[0018] The twist of the two or more glass fiber yarns is 100-150 twists / meter, the linear speed of the feeding is 420-600m / min, and the overfeed rate in the bulked yarn machine is 30-35%; The pressure of the high-pressure airflow is 0.3-0.8MPa; the tension range of the tension adjustment is 25-70CN.

[0019] In order to solve the problems existing in the processing of existing glass fiber bulked yarns, such as large bulking unevenness, many fiber monofilament breakages, and large loss of ya...

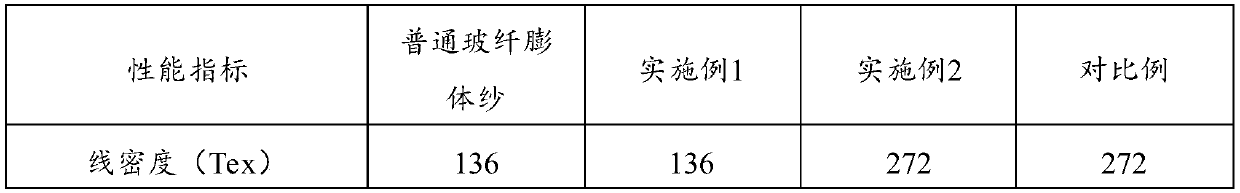

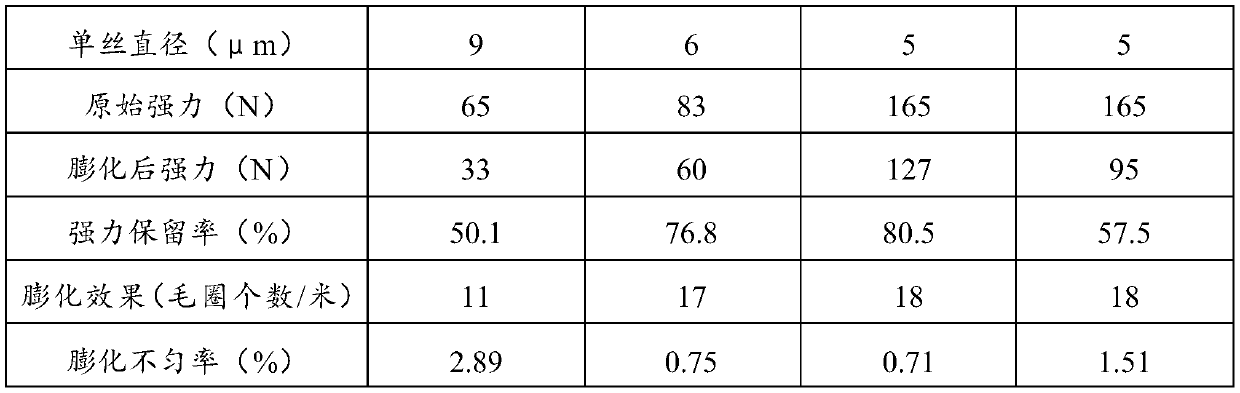

Embodiment 1

[0029] Feed two alkali-free glass fiber yarns with a twist of 100 twists / m into the DST60 glass fiber bulked yarn machine of German Dietzer + Scheer company at the same time, the feeding line speed is 420m / min, and the overfeeding rate is set 30%; the 0.4MPa high-pressure air flow through the high-pressure nozzle is continuously sprayed. The compressed air flow must be a continuous, stable, and clean high-pressure injection. The injection pressure can be adjusted according to the yarn puffing effect, so that the fibers are dispersed and the yarn Fluffy, forming random terry, entanglement, nodules and other bulky states. The expanded inorganic fiber yarn is pre-tensioned by 25CN through the tension adjustment device, and then passed through the yarn guide mechanism and winding device, with a winding line of 300m / min The package with uniform speed is packaged on the bobbin, the package diameter is 350mm, and the winding length is 15000m. After passing the inspection, it is put in...

Embodiment 2

[0031]4 twists are the alkali-free glass fiber yarns of 150 twists / meters fed into the bulked yarn machine (same as Example 1) simultaneously, the feeding line speed is 580m / min, and the overfeed rate is set to 30%; The 0.6MPa high-pressure air flow from the nozzle is continuously injected. The compressed air flow must be a continuous, stable, and clean high-speed injection. The injection pressure can be adjusted according to the puffing effect of the yarn, so that the glass fibers are dispersed with each other, and the inorganic fiber yarn is fluffy as a whole. Form bulky states such as irregular terry, entanglement, and nodules. The expanded inorganic fiber yarn is pre-tensioned by 65CN through the tension adjustment device, and then passed through the yarn guide mechanism and winding device to achieve a uniform winding speed of 305m / min. The package is packaged on the bobbin, the package diameter is 400mm, and the winding length is 12000m. After passing the inspection, it is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Monofilament diameter | aaaaa | aaaaa |

| Winding length | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com