Electroplating sewage treatment method

A sewage treatment method and sewage technology, applied in water/sewage treatment, biological water/sewage treatment, water/sewage multi-stage treatment, etc., can solve problems such as hazards, low treatment efficiency, single treatment method, etc., to improve chemical reaction Strength, save chemical reaction time, improve the effect of treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

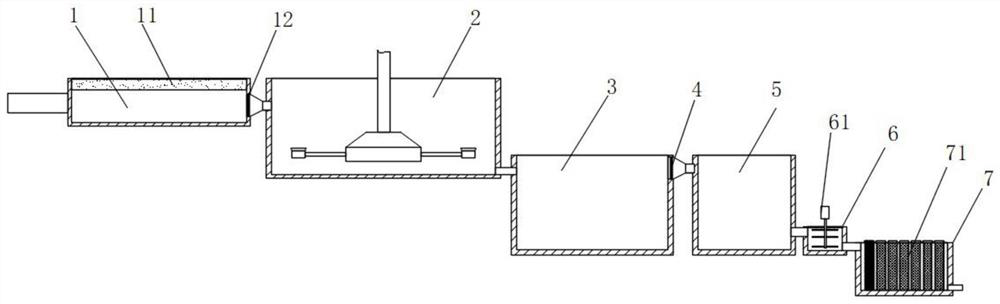

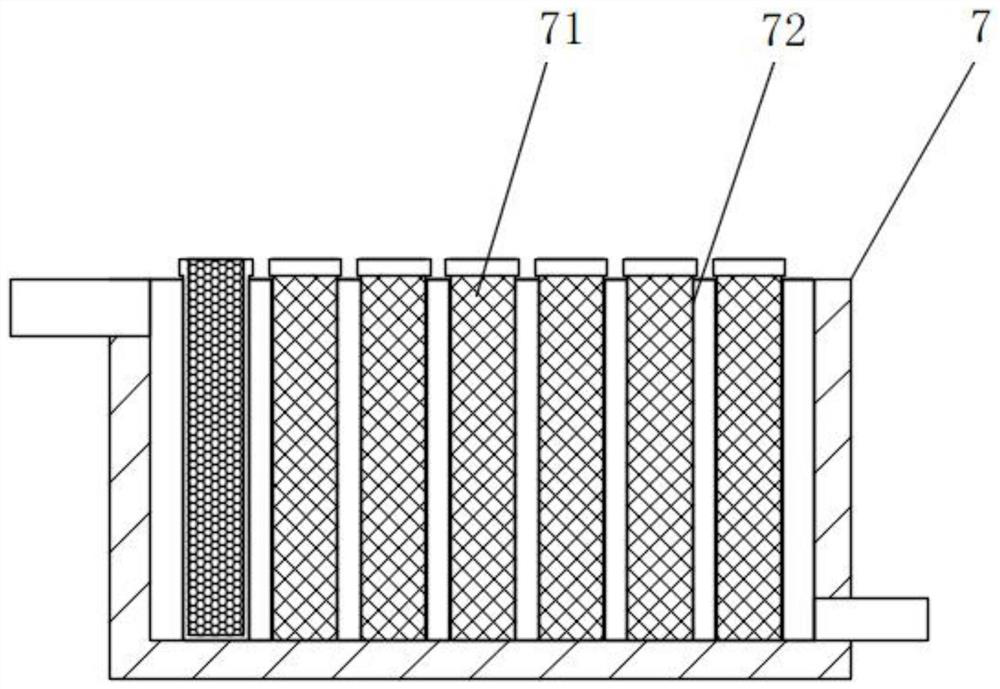

[0029] A method for treating electroplating sewage, comprising the following steps:

[0030] Step 1, preliminary filtration, the electroplating sewage is introduced in the filter tank 1, by placing the oil-absorbing sponge 11 in the filter tank 1, and setting the first filter screen 12 on the other side of the filter tank 1, using the oil-absorbing sponge 11 to treat the sewage The grease substances floating on the surface are adsorbed and filtered, and then the sewage is initially filtered through the first filter screen 12, and then discharged into the aeration tank 2;

[0031] Step 2, chemical reduction, then add 12% FeSO4 solution with a solubility of 80mg / L to the aeration tank 2, then carry out aeration treatment, the treatment time is 20-30min, then add iron to the aeration tank 2 Powder, then carry out aeration treatment, the treatment time is 10-20 minutes, then the sewage is introduced into the sedimentation tank 3;

[0032] Step 3, sedimentation in the sedimentatio...

Embodiment 2

[0044] A method for treating electroplating sewage, comprising the following steps:

[0045] Step 1, preliminary filtration, the electroplating sewage is introduced in the filter tank 1, by placing the oil-absorbing sponge 11 in the filter tank 1, and setting the first filter screen 12 on the other side of the filter tank 1, using the oil-absorbing sponge 11 to treat the sewage The grease substances floating on the surface are adsorbed and filtered, and then the sewage is initially filtered through the first filter screen 12, and then discharged into the aeration tank 2;

[0046]Step 2, chemical reduction, then add 10% FeSO4 solution with a solubility of 78mg / L to the aeration tank 2, then perform aeration treatment, the treatment time is 20-30min, and then add iron to the aeration tank 2 Powder, then carry out aeration treatment, the treatment time is 10-20 minutes, then the sewage is introduced into the sedimentation tank 3;

[0047] Step 3, sedimentation in the sedimentati...

Embodiment 3

[0059] A method for treating electroplating sewage, comprising the following steps:

[0060] Step 1, preliminary filtration, the electroplating sewage is introduced in the filter tank 1, by placing the oil-absorbing sponge 11 in the filter tank 1, and setting the first filter screen 12 on the other side of the filter tank 1, using the oil-absorbing sponge 11 to treat the sewage The grease substances floating on the surface are adsorbed and filtered, and then the sewage is initially filtered through the first filter screen 12, and then discharged into the aeration tank 2;

[0061] Step 2, chemical reduction, then add 15% FeSO4 solution with a solubility of 75mg / L to the aeration tank 2, then perform aeration treatment, the treatment time is 20-30min, and then add iron to the aeration tank 2 Powder, then carry out aeration treatment, the treatment time is 10-20 minutes, then the sewage is introduced into the sedimentation tank 3;

[0062] Step 3, sedimentation in the sedimentat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com