A kind of preparation method of colorless transparent polyimide liquid crystal alignment film

A technology of transparent polyimide and liquid crystal alignment film, applied in liquid crystal materials, chemical instruments and methods, etc., can solve problems such as limiting the application of polyimide materials, and achieve the effect of improving transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

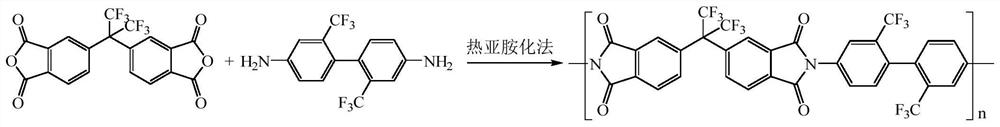

Method used

Image

Examples

Embodiment 1

[0023] Step A): At room temperature, weigh 2.91g of dianhydride monomer 6FDA and 2.05g of diamine monomer TFMB according to the molar ratio of dianhydride monomer 6FDA to diamine monomer TFMB of 1.02:1. Then measure 30 ml of dried DMAC to ensure that the solid content of the reaction system is 15%. Then pour all the diamine monomer TFMB into a dry 50ml reaction container, add 25ml of DMAC and turn on the switch of the magnetic stirrer, wait until the diamine monomer TFMB is completely dissolved, then add the dianhydride monomer 6FDA into the reaction container three times, Each interval is 10 minutes. After the feeding is completed, rinse the residual monomer on the wall of the bottle with 5ml DMAC, and then pass nitrogen gas for 20 minutes. After 12 hours of reaction, a colorless and transparent polyamic acid solution is obtained. Seal the polyamic acid solution and store it in the refrigerator. ready for use. After 12 hours of reaction, the rotational viscosity of the polya...

Embodiment 2

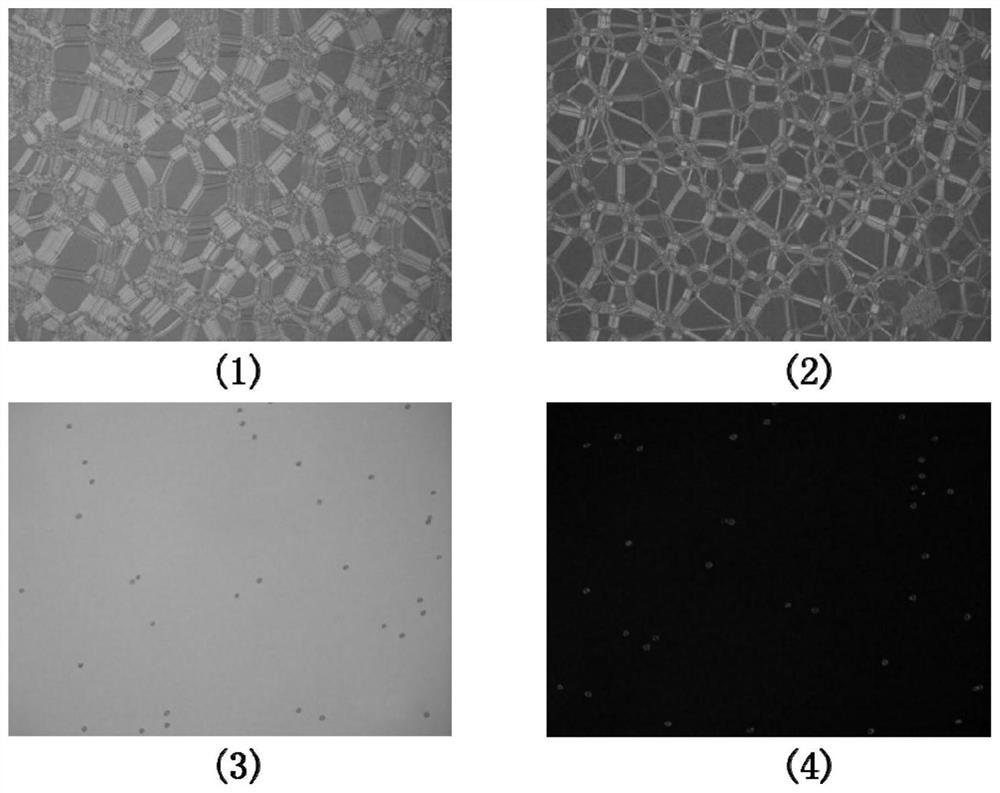

[0026] The difference between Embodiment 2 and Embodiment 1 is that the types of liquid crystals poured in the liquid crystal cell are different. The liquid crystal cell is filled with TEB300 nematic liquid crystal and two kinds of cholesteric liquid crystals. and TEB300 two kinds of nematic liquid crystals were prepared by adding 2% R5011 chiral agent, and then using a polarizing microscope to observe the orientation uniformity of liquid crystal molecules in the cell, as shown image 3 The polarized photogram shown.

[0027] image 3 Middle (1) is the polarized light micrograph of cholesteric liquid crystal after adding 2% chiral agent to E7, (2) is the polarized light micrograph of cholesteric liquid crystal added to TEB300 with chiral agent, (3) and (4) respectively It is the polarized photomicrograph of bright state and black state of TEB300 nematic liquid crystal. It can be seen from the polarized light micrographs that changing the colorless transparent polyimide align...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com