A medical pressure-sensitive silicone gel, its preparation method and application, and a gel product

A silicone gel, pressure-sensitive technology, used in pressure-sensitive films/sheets, adhesives, film/sheet-like adhesives, etc. The skin is prone to sweating and other problems, achieving the effect of not easy human allergic reaction, high viscosity, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

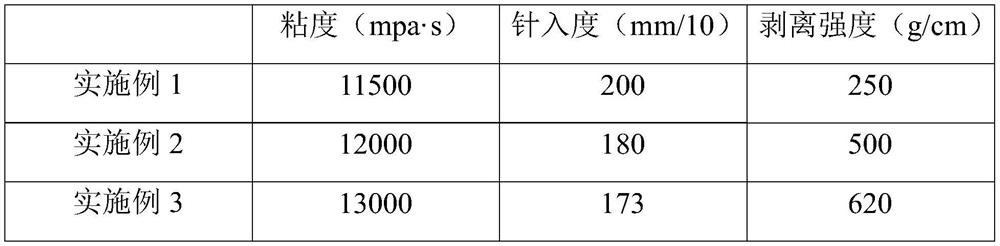

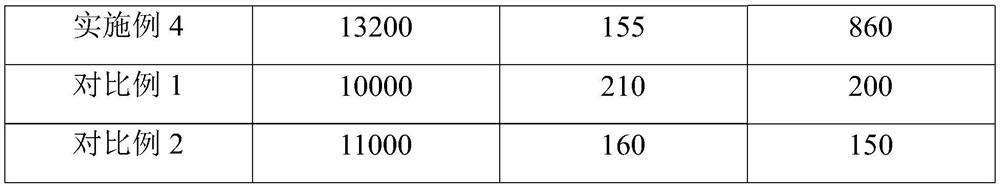

Examples

preparation example Construction

[0063] In addition, the present application also provides a method for preparing the above-mentioned medical pressure-sensitive silicone gel, which may include the following steps: mixing raw materials.

[0064] In an optional embodiment, when the raw material includes a catalyst, the mixing can be performed according to the following steps: mixing part of vinyl silicone oil (such as methylvinylsiloxane-dimethylsiloxane copolymer) and the catalyst to obtain A glue. Mix the remaining vinyl silicone oil (such as methyl vinyl siloxane-dimethylsiloxane copolymer), hydrogen-containing silicone oil (such as polymethyl hydrogen siloxane) and MQ silicone resin to obtain B glue. Then mix the A glue and the B glue.

[0065] Mixing the raw materials of the present application in this order helps to avoid the silicone gel being non-sticky due to the complete curing of the raw materials, and also helps to avoid the formation of an adhesive layer with too strong a structure, so that it can...

Embodiment 1

[0079] The present embodiment provides a medical pressure-sensitive silicone gel, which is prepared by the following method:

[0080] Mix glue A and glue B in a mass ratio of 1:1.

[0081] Among them, the A glue contains 99% of methylvinylsiloxane-dimethylsiloxane copolymer and 1% of platinum complex in terms of weight percentage. The concentration of the platinum complex was 3000 ppm. A glue is obtained by mixing the above two components in a mixer according to the proportion.

[0082] In parts by weight, glue B contains 89% of methylvinylsiloxane-dimethylsiloxane copolymer, 10% of polymethyl hydrogen siloxane and 1% of methyl MQ silicone resin. Glue B is obtained by mixing the above three components in a mixer according to the proportions.

[0083] That is, the final silicone gel contains 94% by weight of methylvinylsiloxane-dimethylsiloxane copolymer, 0.5% by weight of platinum complex, 5% by weight of polymethyl hydrogen siloxane and 0.5% by weight of polymethyl hydroge...

Embodiment 2

[0085] The present embodiment also provides a medical pressure-sensitive silicone gel, which is prepared by the following method:

[0086] Mix glue A and glue B in a mass ratio of 1:1.

[0087] Among them, the A glue contains 99% of methylvinylsiloxane-dimethylsiloxane copolymer and 1% of platinum complex in terms of weight percentage. A glue is obtained by mixing the above two components in a mixer according to the proportion.

[0088] In parts by weight, glue B contains 88% of methylvinylsiloxane-dimethylsiloxane copolymer, 10% of polymethyl hydrogen siloxane and 2% of methyl MQ silicone resin. Glue B is obtained by mixing the above three components in a mixer according to the proportions.

[0089] That is, the final silicone gel contains 93.5wt% methylvinylsiloxane-dimethylsiloxane copolymer, 0.5wt% platinum complex, 5wt% polymethyl hydrogen siloxane and 1 wt% MQ silicone resin.

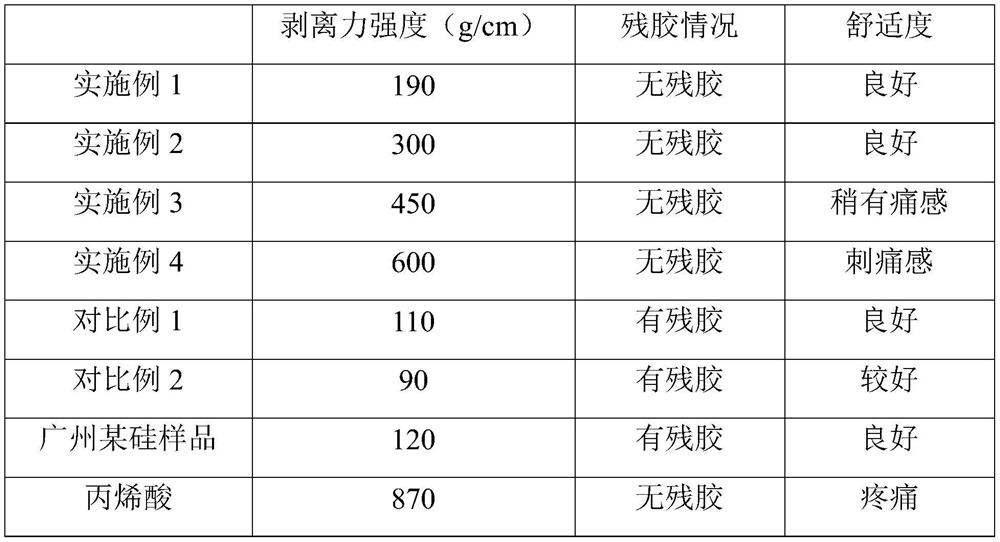

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com