Dyeing, Finishing and Finishing Technology of Back Adhesive of Elastic Leather Products

A leather and adhesive technology, applied in the field of adhesive dyeing, finishing and finishing of elastic leather products, can solve problems such as peeling and falling off, and achieve the effects of solving penetration problems, smoothing the leather surface, and simple and convenient operation of adhesive backing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

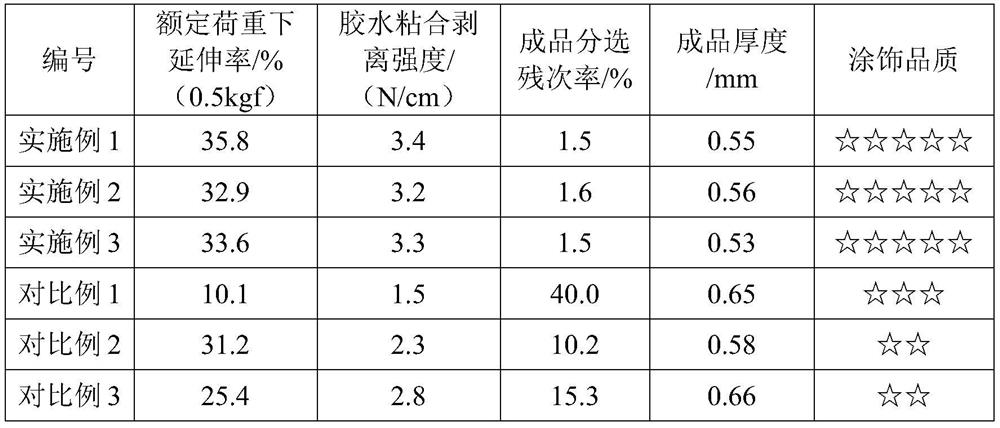

Examples

Embodiment 1

[0084] A process for dyeing and finishing the back glue of elastic leather products, comprising the following steps:

[0085] 1) Carrying out the dry finishing of the elastic leather skin, comprising the following steps:

[0086] ①Water spray: water spray on meat surface, 4 rows;

[0087] ②Stationary: board to board, wrapping film paper and standing for 6-8 hours;

[0088] ③Turn the cage: measure the water content of the board surface at 22°±1, and turn the cage for 2 hours;

[0089] ④ Trimming: Trim the leather-shaped edge;

[0090] ⑤Skin sheeting: Through the sheeting machine, adjust the thickness of the sheeting sheet, one pass horizontally.

[0091] 2) Adhesive: Use a 1500 adhesive machine to bond the skin to the Lycra base fabric. The selected adhesive glue contains the following components in parts by weight: glue DISPERTEC UV-6535 2000 parts, water 3000 parts, crosslinking Agent FIX CR80 parts, Elite thickener F-44 35 parts;

[0092] 3) Stand still: flatten the hor...

Embodiment 2

[0103] 1) Carrying out the dry finishing of the elastic leather skin, comprising the following steps:

[0104] ①Water spray: water spray on meat surface, 4 rows;

[0105] ②Stationary: board to board, wrapping film paper and standing for 6-8 hours;

[0106] ③Turn the cage: measure the water content of the board surface at 22°±1, and turn the cage for 2 hours;

[0107] ④ Trimming: Trim the leather-shaped edge;

[0108] ⑤Skin sheeting: Through the sheeting machine, adjust the thickness of the sheeting sheet, one pass horizontally.

[0109] 2) Adhesive: Use a 1500 adhesive machine to bond the skin with the Lycra base fabric. The selected adhesive glue contains the following components in parts by weight: glue DISPERTEC UV-6535 2000 parts, water 3000 parts, environmentally friendly Type crosslinking agent sac-100 80 parts, thickener AA-481735 parts;

[0110] 3) Stand still: flatten the horse and let stand for 12 hours;

[0111] 4) Backwater: Add the following components in acc...

Embodiment 3

[0121] 1) Carrying out the dry finishing of the elastic leather skin, comprising the following steps:

[0122] ①Water spray: water spray on meat surface, 4 rows;

[0123] ②Stationary: board to board, wrapping film paper and standing for 6-8 hours;

[0124] ③Turn the cage: measure the water content of the board surface at 22°±1, and turn the cage for 2 hours;

[0125] ④ Trimming: Trim the leather-shaped edge;

[0126] ⑤Skin sheeting: Through the sheeting machine, adjust the thickness of the sheeting sheet, one pass horizontally.

[0127] 2) Adhesive: Use a 1500 adhesive machine to bond the skin to the Lycra base fabric. The selected adhesive glue contains the following components in parts by weight: glue DISPERTEC UV-6535 2000 parts, water 3000 parts, crosslinking Agent YZ-93080 parts, thickener DESMOFLEX WB35 parts;

[0128] 3) Stand still: flatten the horse and let stand for 12 hours;

[0129] 4) Backwater: add the following components to the drum in turn according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com