Processing Technology of Fattening Sheep Elastic Leather Products

A processing technology and fattening sheep technology, applied in leather surface treatment, small raw hide/big raw hide/leather/fur treatment, small raw hide/large raw hide/leather skin/fur chemical treatment, etc., can solve the problem of poor quality of elastic leather, High cost, high utilization rate of the second floor, etc., to achieve remarkable treatment effects, good uniformity, and the effect of reducing harmful emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

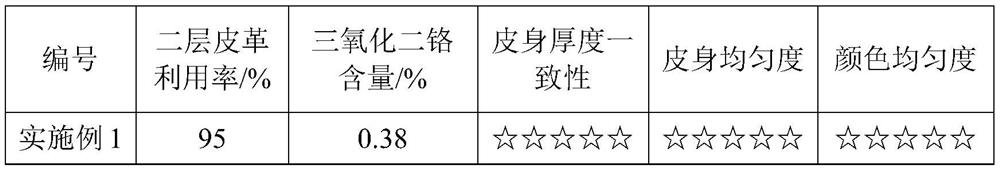

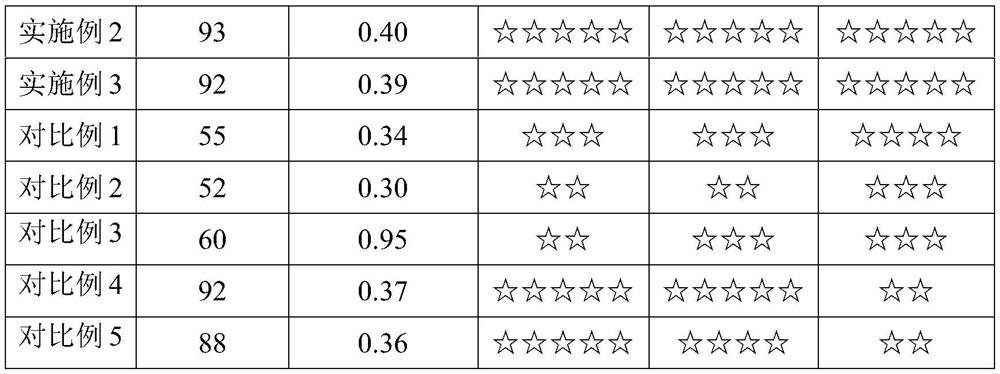

Examples

Embodiment 1

[0070] A processing technology for fattening sheep elastic leather products, comprising the following steps:

[0071] 1) Backwater the elastic leather wet blue skin, and the materials selected for the back water include the following components based on the weight of the wet blue skin: 200% water, temperature 40°C, 0.2% acetic acid, 1% remoisture aid PROSOAK, 0.5% rehumidification aid TERGOLIX CA, add the materials selected for the return water into the drum in turn, and then quickly cast the skin after turning evenly, turn for 60 minutes, drain, and wash with cold water once;

[0072] 2) Retanning: Add the following components in the drum according to the weight of wet blue hides: 100% water, temperature 40°C, 2% tear-resistant fatliquor NZ, 1% universal fatliquor WWL, 0.2% emulsifier SAF, turn for 30 minutes, prefat the wet blue leather after returning to water, then add 0.8% formic acid, turn for 20 minutes, add 6% chrome-containing tannin TANNESCOHN liquid, turn for 60 min...

Embodiment 2

[0083] A processing technology for fattening sheep elastic leather products, comprising the following steps:

[0084] 1) Backwater the elastic leather wet blue skin, and the materials selected for the back water include the following components based on the weight of the wet blue skin: 200% water, temperature 40°C, 0.5% oxalic acid, 1% remoisture aid For PROSOAK, add the materials selected for the backwater into the drum one by one, turn them evenly, and then quickly cast the skins, turn them for 60 minutes, drain them, and wash them with cold water once;

[0085] 2) Retanning: add the following components in the drum according to the weight of wet blue hides: 100% water, temperature 40°C, 2% sulfonated fatliquor TIS, 1% universal fatliquor WWL, 0.2 % emulsifier SAF, rotate for 30 minutes, prefat the wet blue leather after returning to water, then add 0.8% formic acid, rotate for 20 minutes, add 6% chromium-containing tannin TANNESCOHN liquid, rotate for 60 minutes, Add 1% so...

Embodiment 3

[0096] A processing technology for fattening sheep elastic leather products, comprising the following steps:

[0097] 1) Backwater the elastic leather wet blue skin, and the materials selected for the back water include the following components based on the weight of the wet blue skin: 200% water, temperature 40°C, 0.2% acetic acid, 1% remoisture aid PROSOAK, 0.5% rehumidification aid TERGOLIX CA, add the materials selected for the return water into the drum in turn, and then quickly cast the skin after turning evenly, turn for 60 minutes, drain, and wash with cold water once;

[0098] 2) Retanning: Add the following components in the drum according to the weight of wet blue hides: 100% water, temperature 40°C, 2% tear-resistant fatliquor NZ, 1% universal fatliquor WWL, 0.2% emulsifier ML-N, rotate for 30 minutes, prefat the wet blue leather after returning to water, then add 0.8% formic acid, rotate for 20 minutes, add 6% chromium-containing tannin TANNESCOHN liquid, rotate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com