Asphalt paving device for road construction

A laying device and road construction technology, applied in the direction of roads, roads, road repairs, etc., can solve the problems of low mixing effect, increased production costs, and decline in the quality of asphalt pavement, so as to facilitate mixing and laying evenly, avoid temperature drop, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

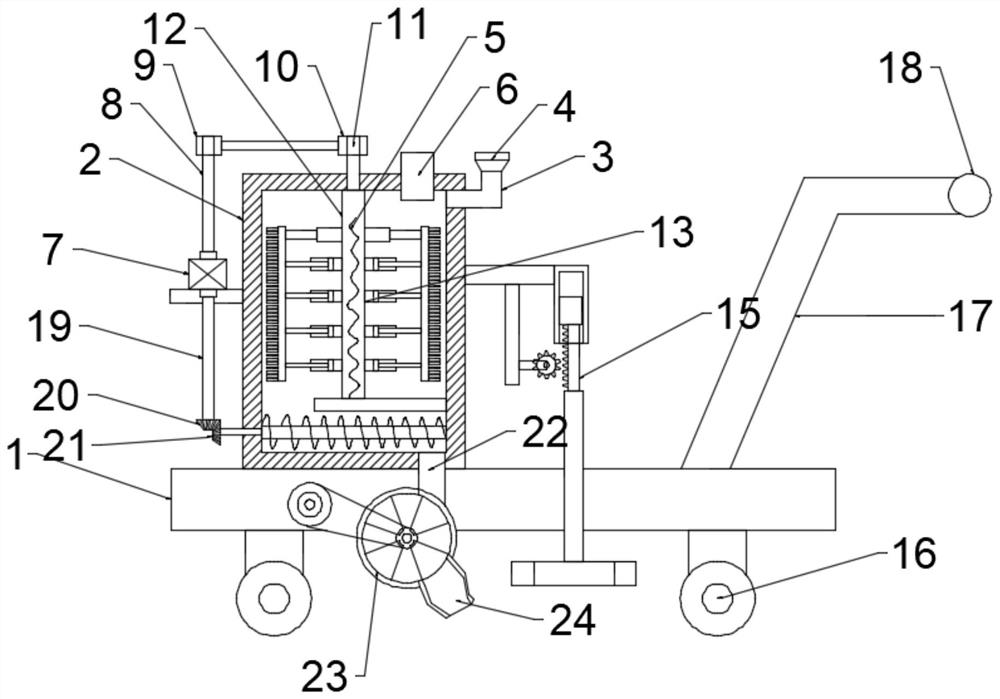

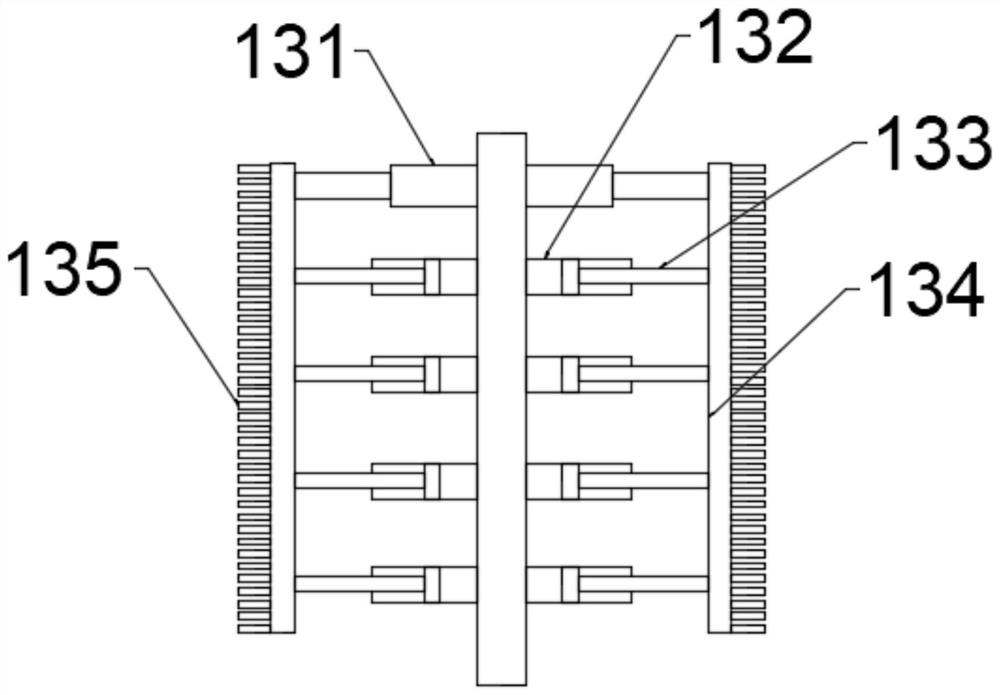

[0023] see Figure 1-2 , in an embodiment of the present invention, an asphalt paving device for road construction, comprising a base plate 1, a tank body 2 is arranged on the upper surface of the base plate 1, and the tank body 2 is divided into an inner layer and an outer layer, and the inner layer and the outer layer A water inlet pipe 3 is arranged between the outer layers, and a water inlet funnel 4 is arranged at the top of the water inlet pipe 3, and a sealing end cover is arranged on the water inlet funnel 4, and a feed inlet 6 is arranged at the top of the tank body 2, so that The outer surface of the left side of the tank body 2 is fixedly connected with a first installation frame, and the upper surface of the first installation frame is provided with a biaxial motor 7, and one end of the biaxial motor 7 is fixedly connected with a rotating shaft 8 through a coupling, so The top end of the rotating shaft 8 is sleeved with a first transmission wheel 9, and the first t...

Embodiment 2

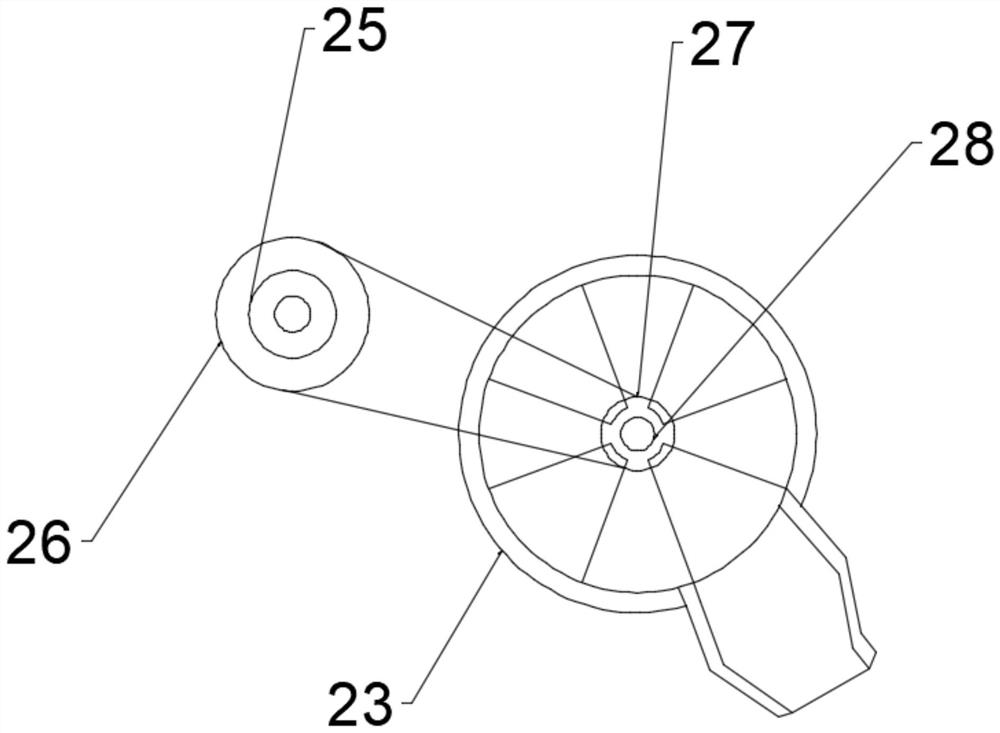

[0027] see Figure 1-4 , in this embodiment, one end of the biaxial motor 7 is fixedly connected with a first rotating shaft 19 through a coupling, and one end of the first rotating shaft 19 is sleeved with the driving bevel gear 20, and one end of the driving bevel gear 20 is meshed with a slave The driven bevel gear 21, one end of the driven bevel gear 21 is fixedly connected with the delivery device 14, the delivery device 14 includes a screw rod 141, the screw rod 141 is provided with a helical blade, and the tank body below the screw rod 141 2 The bottom end is provided with a discharge port 22, and the outlet of the discharge port 22 is provided with a fan-shaped rotating plate 23, and a discharge funnel 24 is provided below the fan-shaped rotating plate 23, and the fan-shaped rotating plate 23 is driven to rotate by a driving mechanism , the biaxial motor 7 drives the first rotating shaft 19 to rotate, and by driving the driving bevel gear 20 to mesh with the driven bev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com