Roof-cutting and roadway-retaining cooperative anchor protection structure and construction method thereof

A construction method and anchor protection technology, which are applied in the directions of bolt installation, earth-moving drilling, ground mining, etc., can solve the problems of poor stability and adaptability of the roadway retaining structure, poor applicability of the roadway retaining technology, and prone to roof accidents. , to achieve the effect of improving stability and adaptability, improving stability and adaptability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] A specific embodiment of the present invention discloses a roof cutting and retaining cooperative anchor protection structure and its construction method that significantly enhance stability and adaptability, including the following steps:

[0074] Step S1: Through the research on the roof cutting principle of the roadway roof pre-splitting blasting, in order to reduce the damage to the roof of the roadway caused by the roof collapse of the goaf during the mining of the working face, the direct roof in the roadway and the roof of the working face are first carried out. Pre-split by directional blasting, cut off the mechanical connection between the direct roof and the roof of the working face, and reduce the damage to the roof in the roadway caused by the collapse of the roof in the goaf after mining. The blasting pre-splitting between the direct roof in the roadway and the roof of the working face includes the following steps:

[0075] Step S11: Before mining at the wo...

Embodiment 2

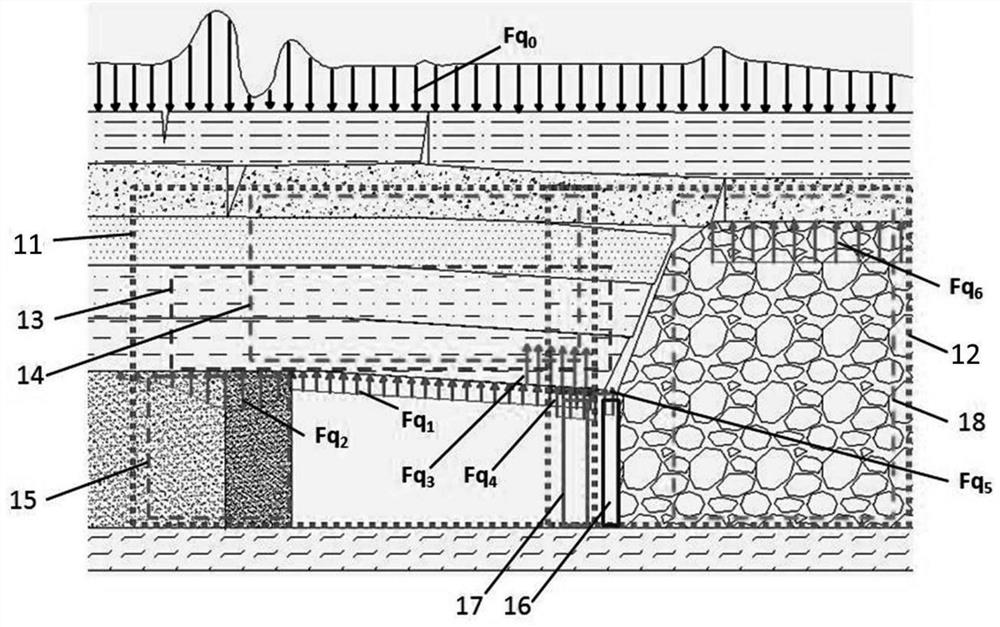

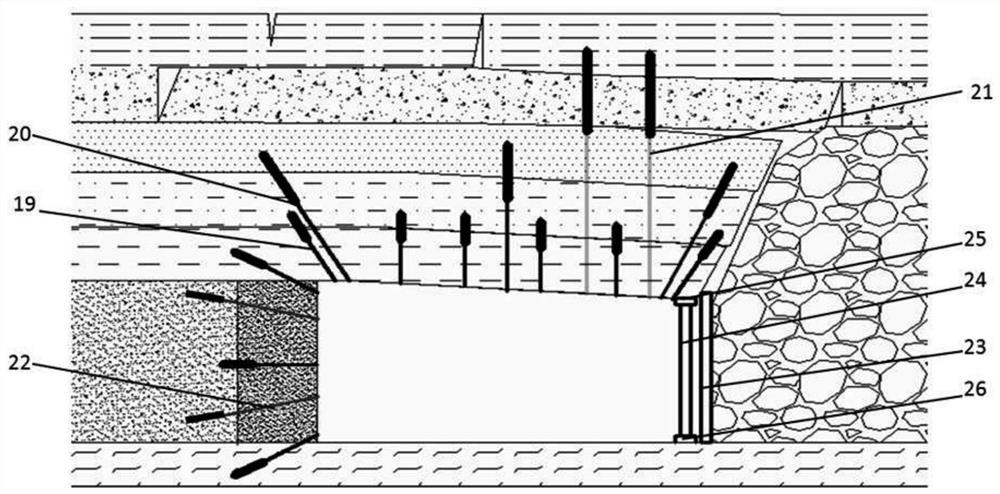

[0128] Yet another specific embodiment of the present invention discloses a collaborative anchoring structure for roof cutting and roadway retention, which is constructed using the construction method in Example 1. The supporting structure 12 is composed of two substructures; the roadside cooperative anchoring structure 11 is composed of roof anchor beam 13, roadside reinforcing beam 14, and coal side anchoring body 15; The protection body 16, the roof cutting support body 17, and the gangue support body 18 are composed of three secondary substructures.

[0129] figure 2 It shows three sub-structures of roof anchor beam 13, roadside reinforced beam 14, and coal side anchor body 15 of roadside cooperative anchoring structure 11, as well as gangue retaining body 16 and roof cutting structure 12 of roadside cooperative support structure 12. The spatial positional relationship of the three secondary substructures of the supporting body 17 and the gangue supporting body 18. By s...

Embodiment 3

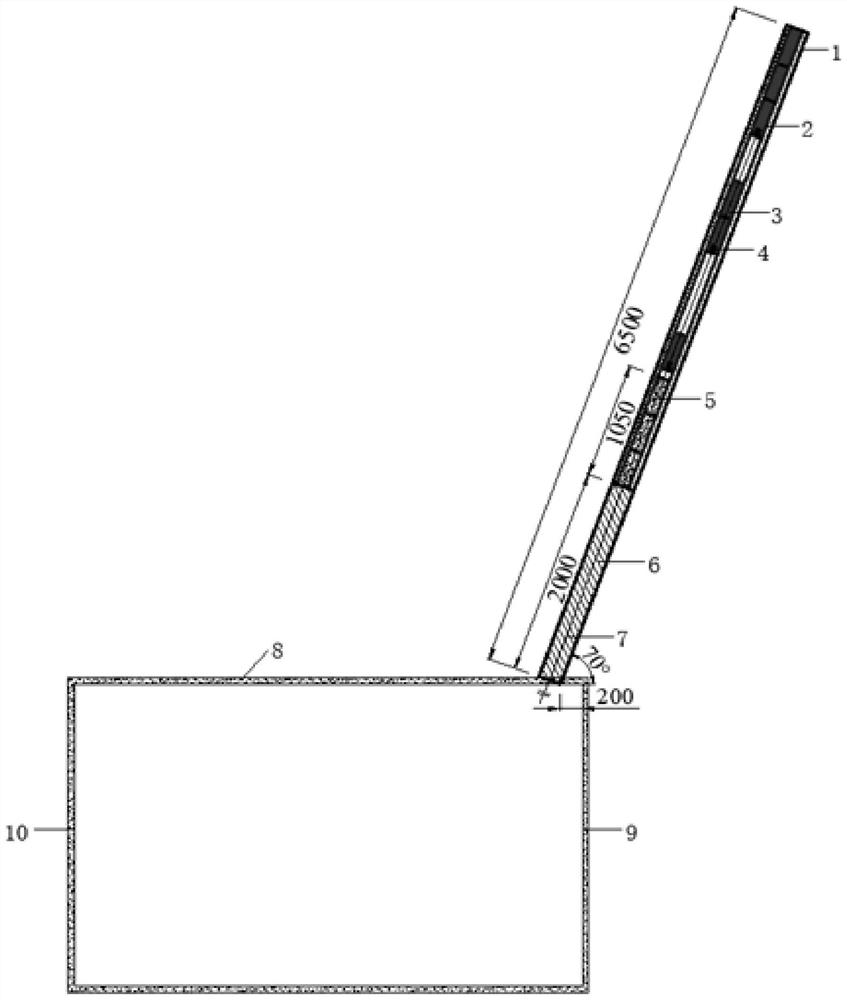

[0135] The pre-split roof cutting effect of directional blasting is one of the key factors determining the effectiveness of gob-side entry retention. It is necessary to design reasonable blasting positions and blasting parameters to promote the formation of good through-cracks between adjacent blastholes and significantly reduce the number of goaf roofs. The influence and degree of damage to the roof of the roadway during the collapse are also conducive to the full collapse of the roof in the goaf, thereby significantly enhancing the stability, adaptability and applicability of the anchorage structure of the gob-side entry retention. A specific embodiment of the present invention discloses the blasthole plugging device in step S14 in embodiment 1, which can detachably plug the blasthole 1 and facilitate the detection of the effect of pre-splitting blasting, such as Figures 4 to 9 As shown, the blasthole blocking device includes a blasthole internal damping device and a blastho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com