Butterfly device for grading system

A grading system and butterfly valve technology, applied in the direction of valve device, valve operation/release device, valve lift, etc., can solve the problems of damaging the printed product printing system, difficulty in effectively closing the butterfly valve, and increasing the difficulty of closing, so as to maintain barrier, The effect of precise feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

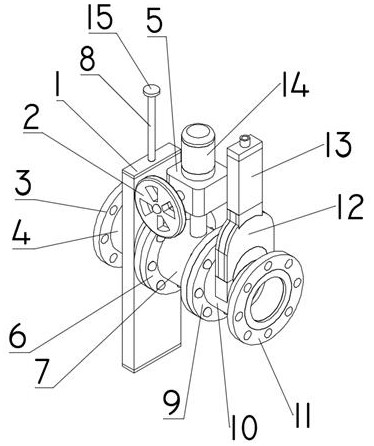

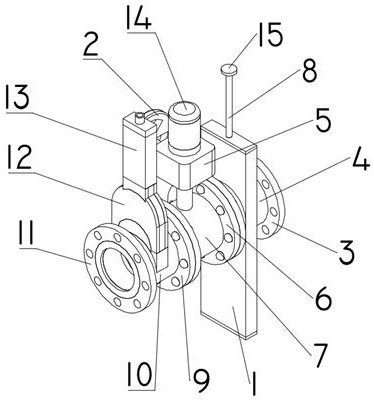

[0023] Such as Figure 1~2 As shown, a classification system butterfly valve device includes a first throttling structure, a second throttling structure and an emergency stop structure. The first throttling structure includes a first conduit 4, a first stop chamber 1, a first valve plate, The first valve stem 8 and the spring, the middle part of the first conduit 4 is connected with the first stop chamber 1 by welding, the middle part of the first conduit 4 communicates with the first stop chamber 1, and the middle part of the first valve plate is provided with The through hole, the first valve plate and the spring are all arranged inside the first stop chamber 1, and the two ends of the spring are respectively connected with the first valve plate and the inner wall of the first stop chamber 1 by welding, and the first valve stem One end of 8 is connected with the first valve plate by welding, and the other end of the first valve rod 8 is arranged outside the first stop chambe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Stiffness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com