Gas-fired boiler cooperative operation method based on accurate control technology

A technology of gas boiler and control technology, which is applied in the direction of control system, program control, general control system, etc., and can solve the problems that the type of gas cabinet cannot meet the regulation of surplus gas fluctuations, and the gas cabinet has a large volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

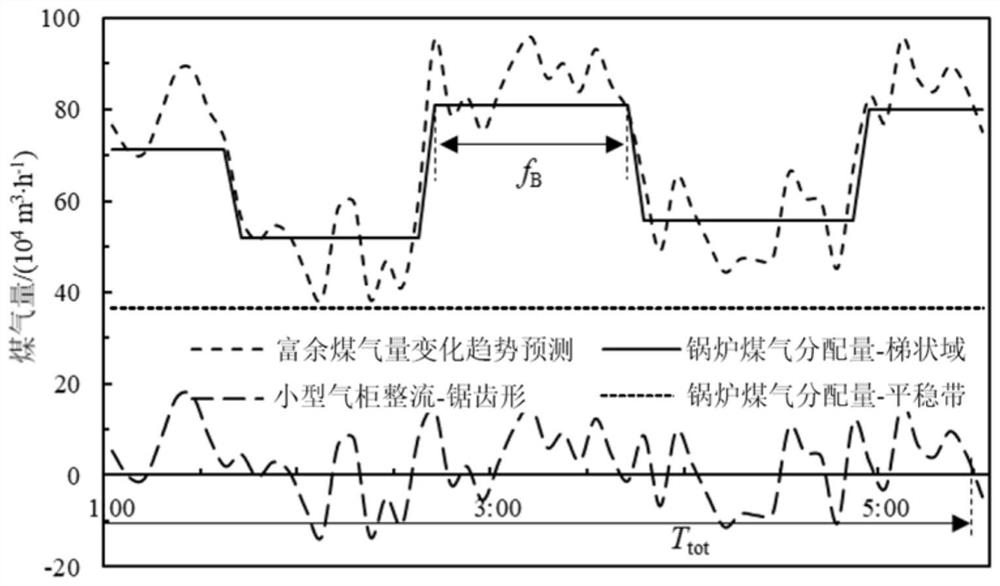

[0079] The regulation process of the surplus gas in the buffer system is as follows: figure 2 shown. figure 2 Listed in the "surplus gas volume change prediction value", "surplus gas smooth zone", "surplus gas ladder region" and "small gas tank rectification - sawtooth" gas flow rectification matching control process.

[0080] As a gas resource handling device, the gas tank has the function of "looper", and uses it to handle the small gas flow (zigzag shape) with frequent fluctuations that deviate from the mean value; It absorbs that part of the large gas flow that rises and falls in a stepped shape (smooth band and stepped shape). As a throughput device, the gas tank is characterized by its small throughput capacity, adapting to frequent fluctuations, small volume and short time, and good effect of adjusting the pressure of the pipe network. As a buffer user, the gas-fired boiler is characterized by its large buffer capacity, adapting to fluctuations of stability, large v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com