Multi-contact high-current elastic terminal and connector with same

A technology of elastic terminals and high current, applied in the direction of connection, contact parts, parts of connection devices, etc., can solve the problems of poor conductivity, weak current carrying capacity, high cost, etc., and achieve small overall structure volume and increase contact area , good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is further described in conjunction with the following examples.

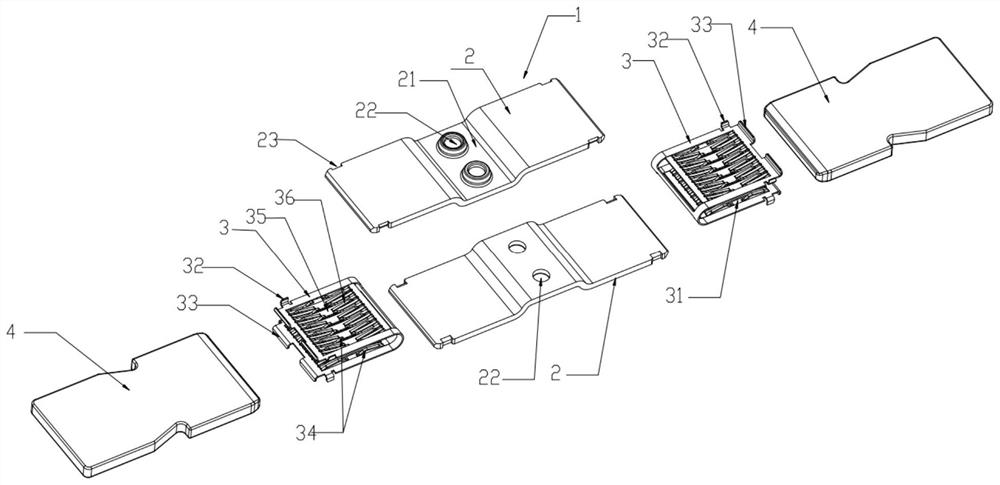

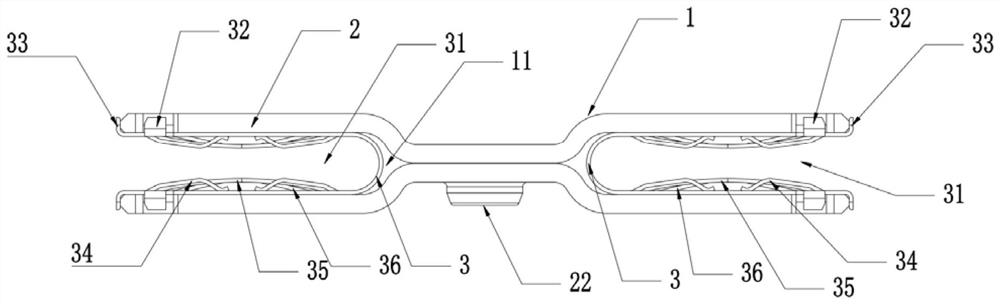

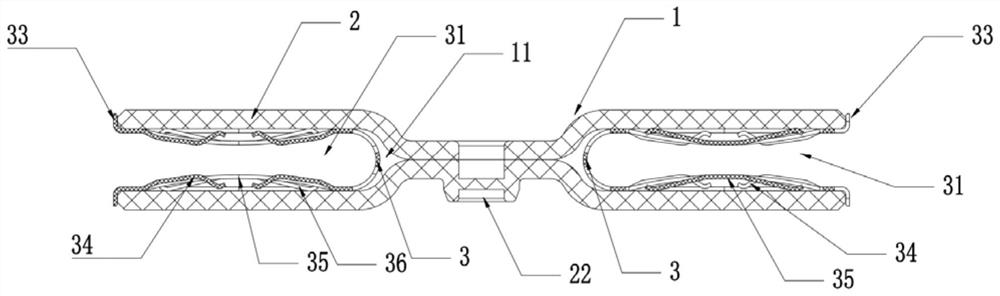

[0031] A specific embodiment of a multi-contact high-current elastic terminal of the present invention, such as figure 1 with figure 2 As shown, its structure includes a terminal body 1 and a contact spring 3 , and the terminal body 1 is provided with a U-shaped flat accommodation groove 11 . Specifically, the terminal body 1 includes two sheet metal sheets 2, the middle of the metal sheet 2 is punched and formed with a recessed portion 21, and the recessed portion 21 is provided with a riveting hole 22, and the middle of the two sheet metal sheets 2 is inserted into the rivet In the riveting hole 22, the riveting fixed connection is further realized. Such as figure 2 with image 3 As shown, the grooves formed by the two ends of the two sheet metal pieces 2 are respectively accommodating grooves 11, and the contact springs 3 can be inserted into the accommodating grooves 11 at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com