Excavator bucket for shoveling soil of agricultural machinery

A technology for agricultural machinery and shoveling, which is used in mechanically driven excavators/dredgers, earthmovers/shovels, construction, etc., which can solve the problem that the service life of the bucket body is greatly affected and the wear of the inner bottom of the bucket is increased. , affecting the cleanliness and beauty of the road surface, etc., to achieve the effect of high overall structural strength, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

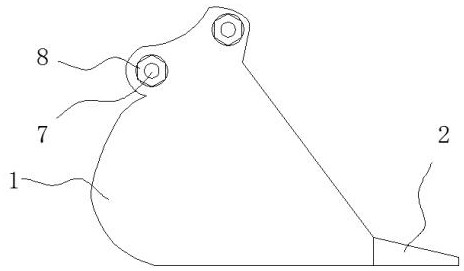

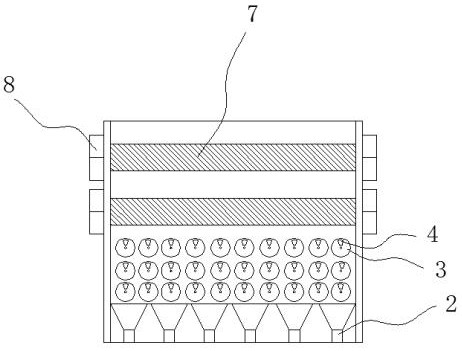

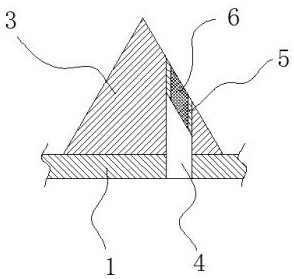

[0015] refer to figure 1 , figure 2 and image 3 The shown bucket for shoveling of agricultural machinery comprises a bucket body 1, a digging tooth 2 arranged on the bucket body 1, and a crushing tooth 3 arranged on the bucket body 1, and the digging tooth 2 is arranged on the bucket body 1. Welded and fixed at the front end of the bucket body 1, the crushing teeth 3 are arranged at the upper surface of the inner bottom of the bucket body 1, and a through hole is provided at the rear side of the crushing teeth 3 to facilitate water flow out 4. The lower part of the through hole 4 is set through the bottom of the bucket body 1, and a fixing frame 5 is welded at the upper part of the inner wall of the through hole 4, and the fixing frame 5 is provided with a retaining net 6, and the retaining net The upper surface of the bucket 6 and the rear side surface of the crushing teeth 3 are arranged in the same plane, and two connecting shafts 7 are arranged between the two sides of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com