Constant-pressure stabilizing device of diesel engine preheating system

A stabilizing device and diesel engine technology, applied in the direction of fuel heat treatment device, charging system, engine starting, etc., can solve the problem of large fluctuations in diesel pressure and flow, affecting the normal operation of flame glow plugs, flame injection preheaters, etc. Damage and other problems, to achieve the effect of occupying less space for the diesel engine, facilitating normal operation, solving the problem of stabilizing diesel pressure and balancing diesel flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

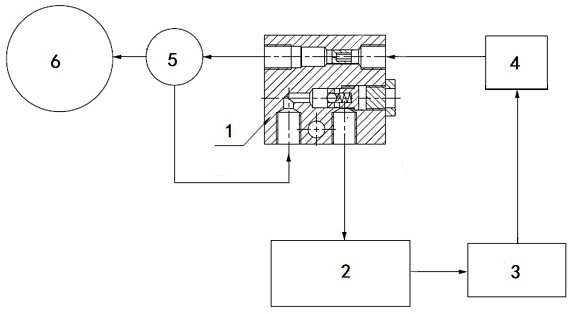

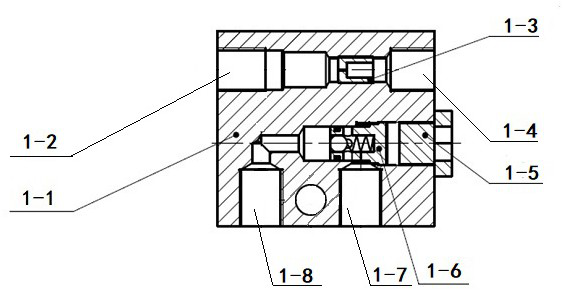

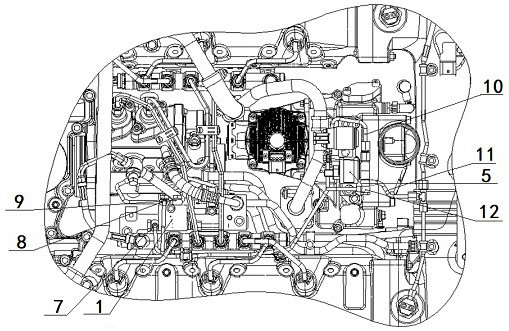

[0026] The present invention aims at the shortcomings in the prior art, and develops a constant pressure stabilization device for the diesel engine preheating system. An oil inlet pipeline and an oil return pipeline are arranged inside the communication valve. The two pipelines operate independently without interfering with each other, and can realize In the high-pressure common rail diesel engine preheating system, the function of reducing the oil inlet pressure and flow, stabilizing the oil pressure of the oil supply pipeline, and ensuring the normal flow direction of diesel oil is used to solve the problem of stabilizing diesel pressure and balancing diesel oil in the high-pressure common rail diesel engine flame preheating diesel pipeline flow problem.

[0027] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0028] Such as figure 1 As shown, a constant pressure stabilizing device for a diesel engine preheating system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com