On-site surveying and mapping work system for engineering surveying and mapping

A working system and on-site technology, applied in leaf springs, non-rotating vibration suppression, supporting machines, etc., can solve problems such as easy to shift, cannot meet the needs of production and life, and cumbersome disassembly and assembly of bolts, etc., to achieve enhanced frictional resistance , fixation and stability, and the effect of slowing down the shock force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

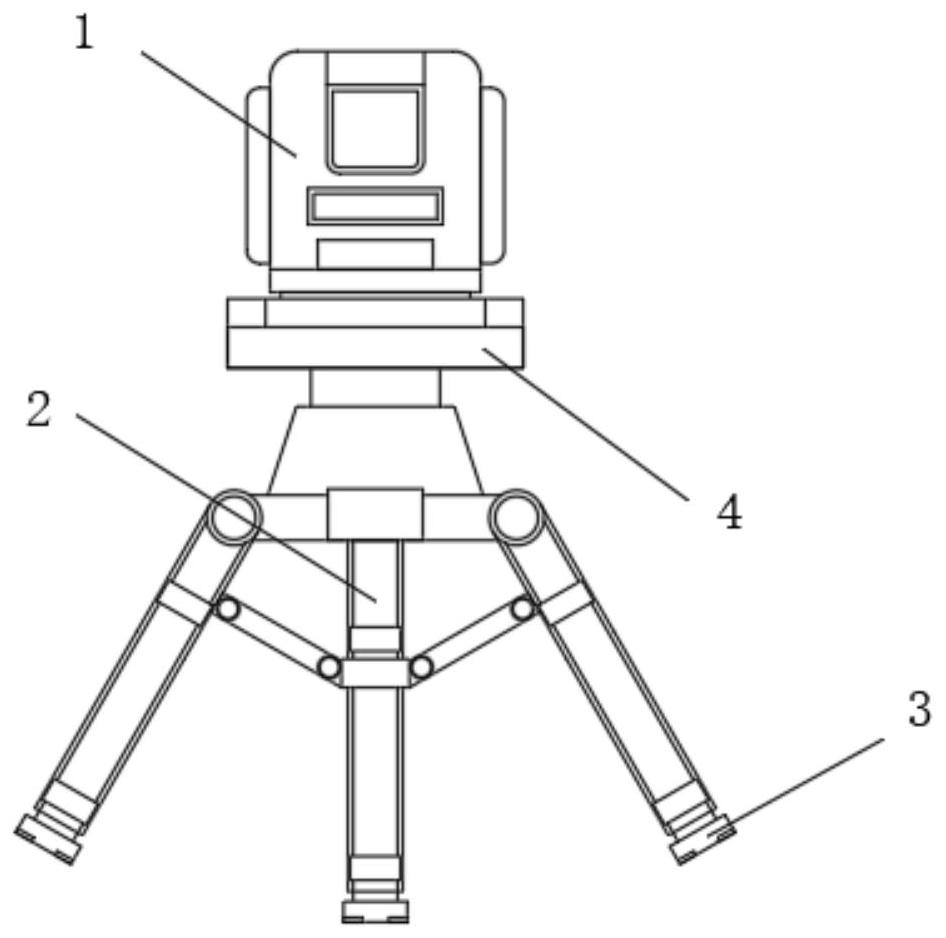

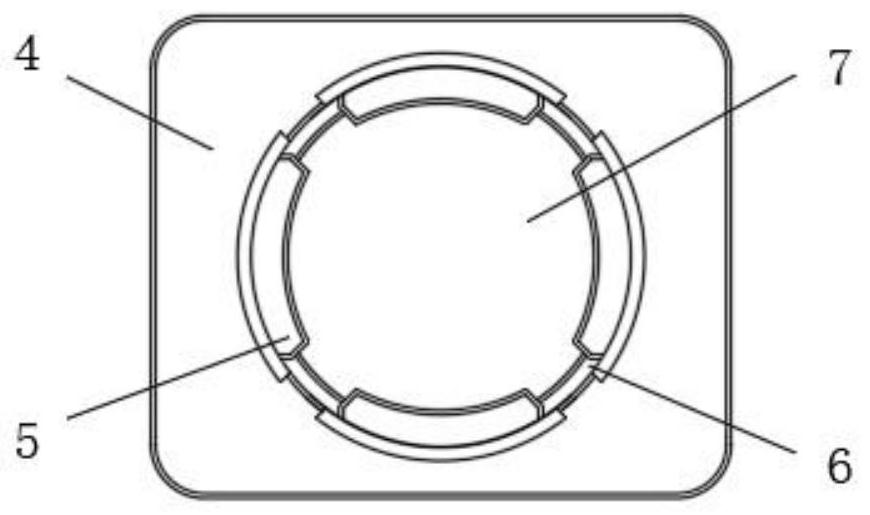

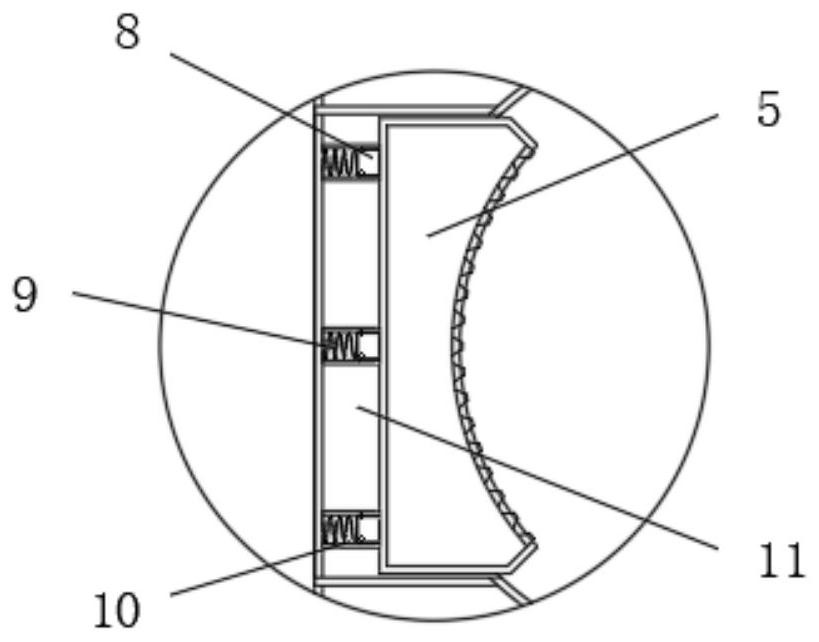

[0030] Please refer to figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention provides an on-site surveying and mapping work system for engineering surveying and mapping, including a surveying and mapping machine body 1, a tripod 2 and a fixed seat 4, the fixed seat 4 is fixed on the top surface of the tripod 2, and the top surface of the tripod 2 is provided with a mounting groove 6, The bottom surface of the installation groove 6 is fixedly connected with a gasket 7, the inside of the bottom end of the fixed seat 4 is fixedly connected with a buffer pad 12, and the bottom surface of the fixed seat 4 is fixedly connected with a rubber pad 13, and the outer contour of the rubber pad 13 is a wave-shaped structure. , the bottom of the surveying and mapping machine body 1 is fixed inside the installation groove 6, the inner wall of the installation groove 6 is provided with a storage groove 11, and the inside of the storage groove 11 is provided with a fa...

Embodiment 2

[0033] Please refer to figure 1 , Figure 5 , Figure 6 and Figure 7 As shown, the present invention provides a field surveying and mapping work system for engineering surveying and mapping, comprising a surveying and mapping machine body 1, a tripod 2 and a fixing seat 4, the bottom of the tripod 2 is fixedly connected with a base 3, and both sides of the bottom of the base 3 are provided with square grooves 15. The inside of the square groove 15 is provided with a bottom plate 14, the bottom surface of the bottom plate 14 is flush with the bottom surface of the base 3, the bottom surface of the bottom plate 14 is fixedly connected with anti-skid lines 16, and the top surface of the bottom plate 14 is fixedly connected with a slide rail 18 , the cross section of the slide rail 18 is a "T" shaped structure, the outer end profile of the slide rail 18 is a circular arc structure, the top surface of the square groove 15 is provided with a slide groove 17, and the slide rail 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com