High-voltage-resistant clamping circuit with alternating current detection and direct current detection

A technology of DC detection and AC detection, which is applied in the direction of emergency protection circuit devices, circuit devices, and measurement of electrical variables for limiting overcurrent/overvoltage, and can solve the problem of affecting the normal working state or function of the chip, and the working voltage of the circuit cannot exceed Device withstand voltage, limitations and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

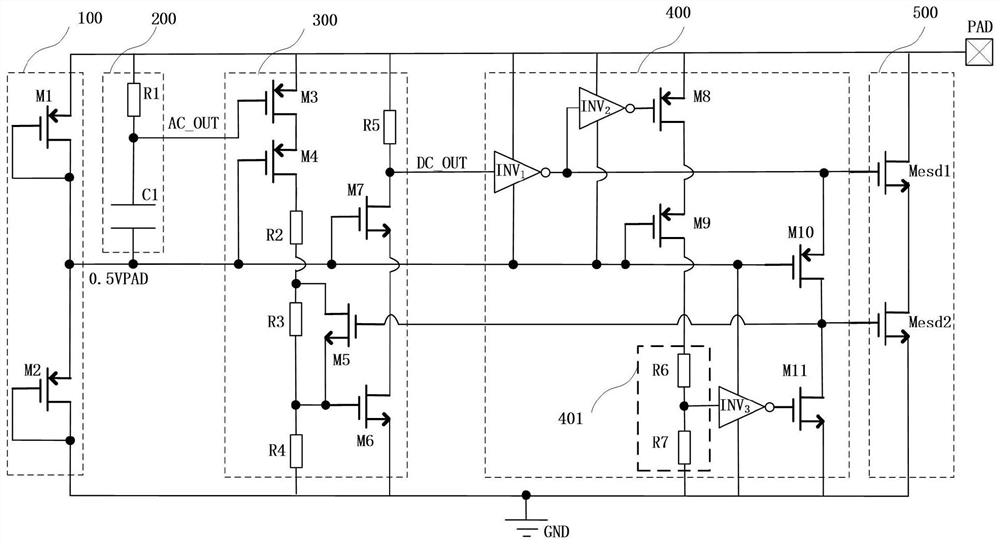

[0025] To provide a preferred implementation manner, the DC detection module 300 includes a third field effect transistor M3, a fourth field effect transistor M4, a fifth field effect transistor M5, a sixth field effect transistor M6, a seventh field effect transistor M7, The second resistor R2, the third resistor R3, the fourth resistor R4 and the fifth resistor R5, the source of the third field effect transistor M3 is connected to PAD, the gate of the third field effect transistor M3 is connected to the AC_OUT line connection, the drain of the third field effect transistor M3 is connected to the source of the fourth field effect transistor M4, the gate of the fourth field effect transistor M4 is connected to the 0.5VPAD line, and the fourth field effect transistor M4 The drain of the field effect transistor M4 is connected to one end of the second resistor R2, and the other end of the second resistor R2 is connected to the drain of the fifth field effect transistor M5 and one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com