Saw device with composite substrate for ultra high frequencies

A carrier substrate, positive frequency technology, applied in the direction of electrical components, impedance networks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

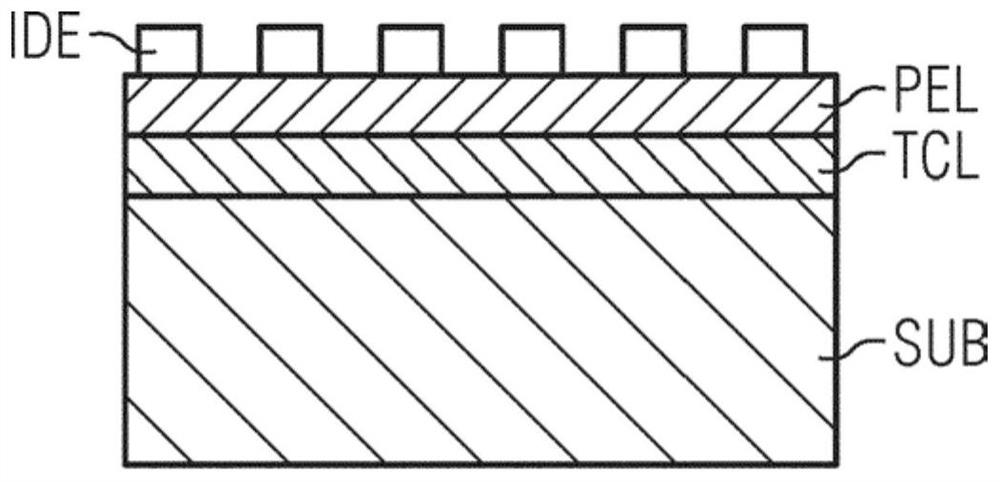

[0031] figure 1 The stack design of a SAW device according to the invention is shown in a schematic cross-sectional view. The carrier substrate SUB comprises a material with a high sound velocity. This thickness is sufficient to be mechanically stable for further handling and manipulation of the SAW device. A thin TCF compensation layer TCL is applied on the substrate and has a positive TCF adapted to compensate the negative TCF of other materials in the stack.

[0032] The next layer is the thin-film piezoelectric layer PEL, which needs to provide proper wave excitation and exhibit a suitably high electromechanical coupling. On the top interdigitated electrode IDE it is arranged to include a metallization adapted to provide the SAW device function of exciting the SAW and recovering electrical signals therefrom. Preferably, the interdigitated electrodes IDE form a resonator. Multiple resonators can form a filter in a ladder or lattice arrangement. However, the interdigita...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com