Charging pile thermal management system

A thermal management system and charging pile technology, applied in charging stations, electric vehicle charging technology, electric vehicles, etc., can solve the problems of occupying the installation space of charging piles, high cost, etc., so as to improve the cooling rate, improve the efficiency, and reduce the use cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

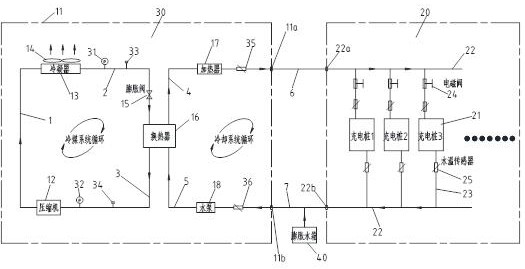

[0028] The charging pile thermal management system of this embodiment includes: a thermal management unit 30 , a charging pile module 20 , a sixth conduit 6 , and a seventh conduit 7 . The heat management unit 30 includes a device housing 11, a compressor 12, a first conduit 1, a condenser 13, a blower 14, a second conduit 2, an expansion valve 15, a plate heat exchanger 16, a third conduit 3, a heating Device 17, water pump 18, fourth conduit 4, fifth conduit 5; wherein compressor 12, condenser 13, blower 14, expansion valve 15, plate heat exchanger 16, heater 17, water pump 18 and each conduit are all installed in device housing 11. The compressor 12, the condenser 13, the expansion valve 15, and the plate heat exchanger 16 form a closed loop through the first conduit 1, the second conduit 2, and the third conduit 3, and a refrigerant flows ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com