Surfboard spray pump structure with rapid heat dissipation effect

A technology of heat dissipation effect and surfboard, applied in the field of surfboard, can solve the problems of affecting the service life of the power source, and the heat of the power source is difficult to dissipate quickly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

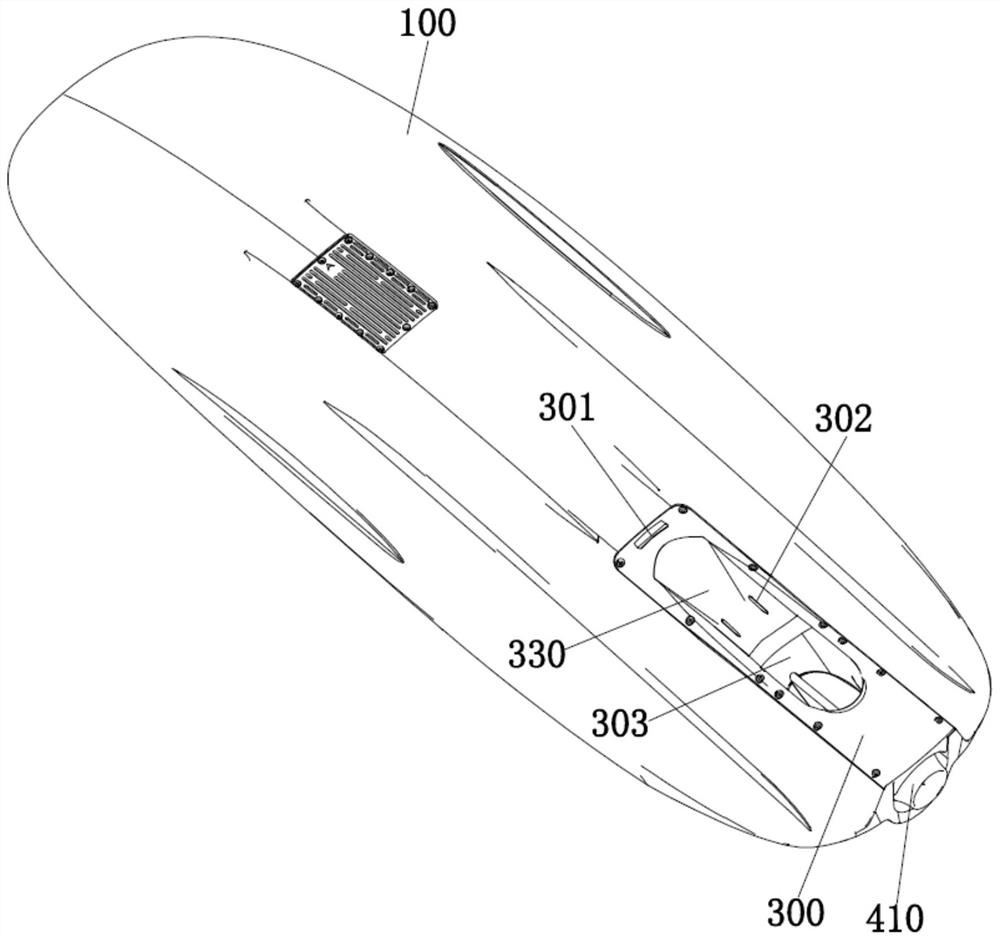

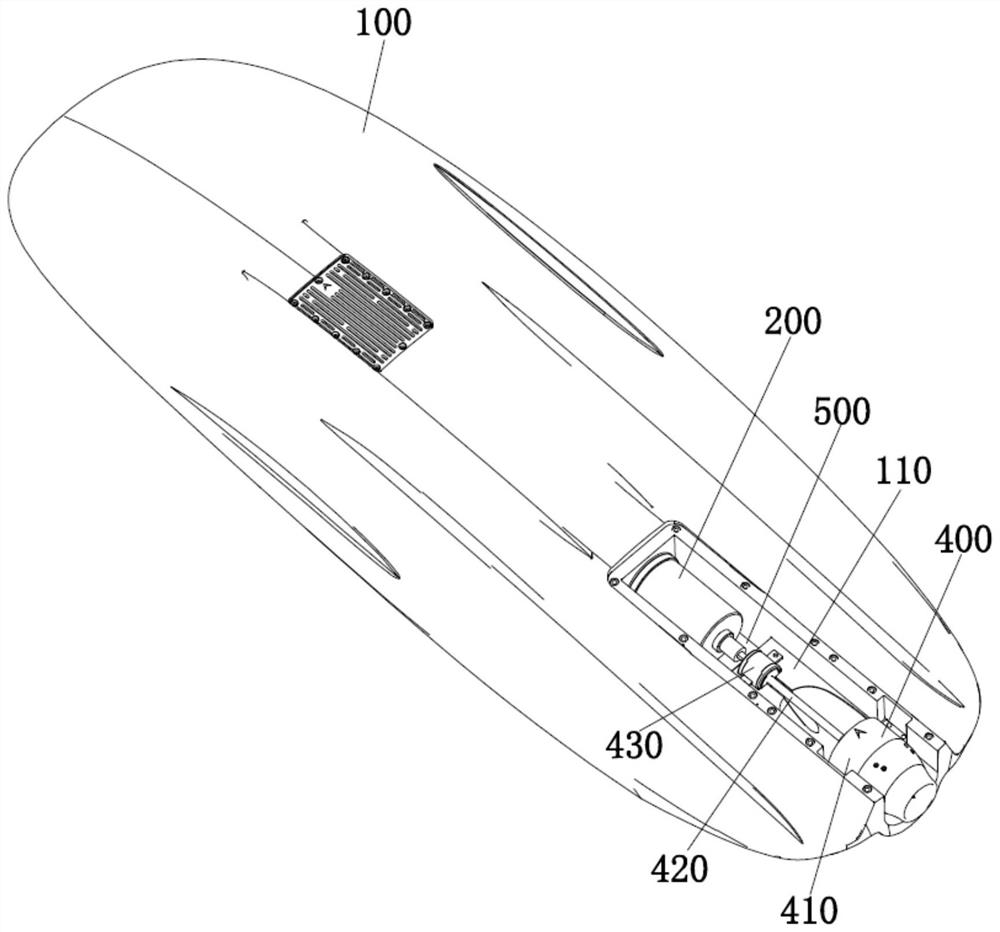

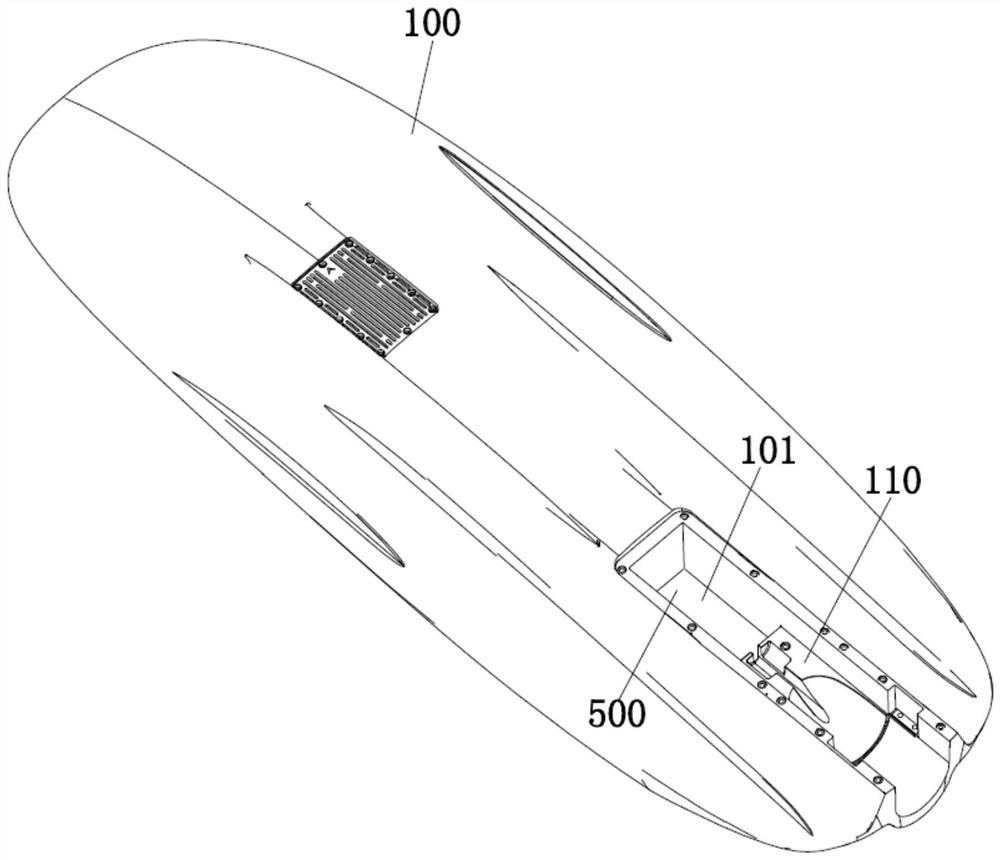

[0028] This embodiment relates to a surfboard jet pump structure with rapid heat dissipation effect, such as Figure 1-5 As shown, the bottom plate 100 of the surfboard is provided with an installation groove 101, and the jet pump structure is arranged in the installation groove 101, and the jet pump structure includes: a power source 200, a propeller assembly 400 and a main channel bottom cover 300.

[0029] Specifically, such as Figure 1-5 As shown, the power source 200 is fixedly installed in the mounting groove 101 on the side away from the tail of the surfboard, and the power source 200 is used to drive the propeller assembly 400 to move the surfboard. The propeller assembly 400 is fixedly installed in the installation groove 101 and fixedly assembled with the power output shaft of the power source 200 . The propeller assembly 400 is used to propel the water flow to the opposite side of the surfboard, so as to propel the surfboard to move by reverse thrust. The bottom ...

Embodiment 2

[0041] The difference between this embodiment and embodiment 1 mainly lies in, as Figure 6 As shown, in this embodiment, the bottom cover plate 300 of the sprue includes: a fixed A plate 340 and a fixed B plate 350 . The fixed A plate 340 is assembled with the side of the installation groove 101 away from the propeller assembly 400 , and the fixed A plate 340 is used to form the installation cavity 500 in combination with the installation table 110 and the installation groove 101 . The fixed B plate 350 is assembled with the side of the installation groove 101 close to the propeller assembly 400 . Dividing the main channel bottom cover 300 into two parts for marble assembly not only avoids the situation that the entire main main channel bottom cover 300 needs to be completely replaced due to damage to any one of the fixed A plate 340 or the fixed B plate 350, but also facilitates Separate access to power source 200 and to screw assembly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com