High-saturation optical color-changing material and preparation method thereof

A technology of optical color-changing materials and evaporation method, which is applied in the field of optical color-changing materials and their preparation, can solve the problems that optical color-changing materials are difficult to meet the needs of use, and achieve the effect of compact structure and improved hue saturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

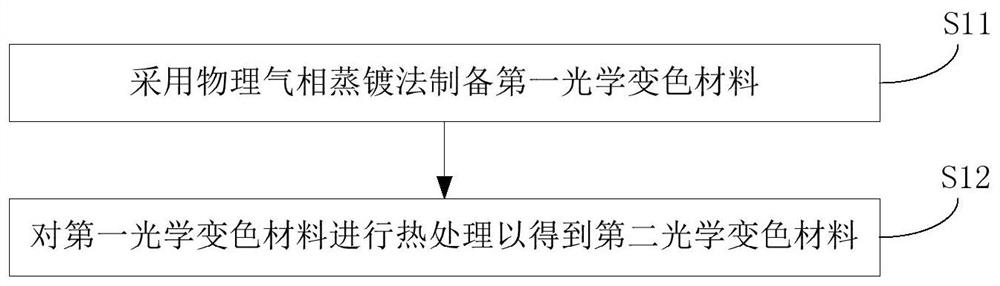

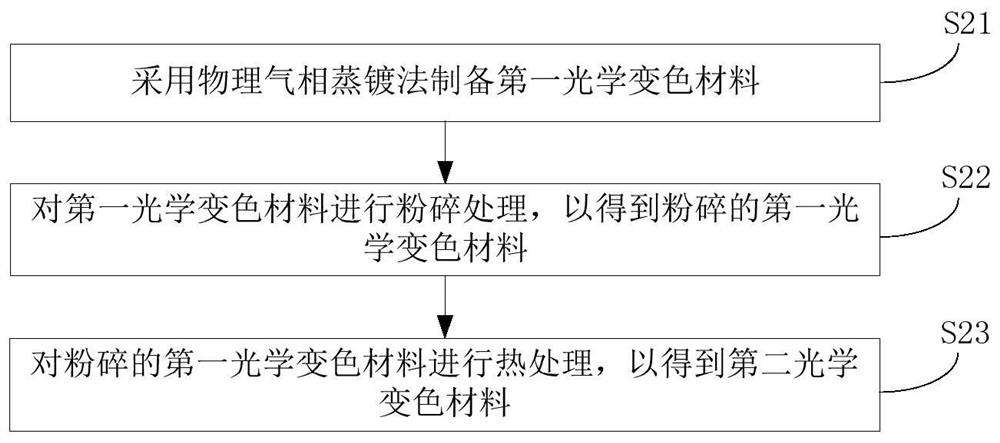

[0021] see figure 1 , figure 1 It is a schematic flow diagram of an embodiment of the preparation method of the optical color-changing material of the present application, and the method includes:

[0022] Step S11: preparing the first optically variable material by physical vapor deposition;

[0023] Step S12: performing heat treatment on the first optically variable material to obtain a second optically variable material.

[0024] Specifically, both the first optically variable material and the second optically variable material can be at least one of titanium-containing optically variable materials, chromium-containing optically variable materials, all-dielectric optically variable materials, etc. Of course, other optically variable materials can also be used , not specifically limited here.

[0025] Further, both the first optically variable material and the second optically variable material can be pigments, such as pigments in powder, granular or flake form, or can al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com