Construction method of replacement type internally-inserted profile steel fender post based on MJS construction method

A construction method and technology of retaining piles, which are applied in foundation structure engineering, excavation, sheet pile walls, etc., can solve the problems of high pile strength and wide lap length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

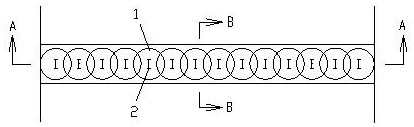

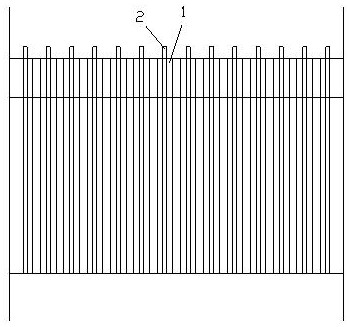

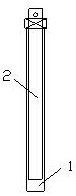

[0028]Implementation examplefigure 1 ,figure 2 withimage 3 As shown, the construction method of the replacement inserted steel enclosure pile based on the MJS construction method of the present invention includes the following steps:

[0029]Step 1. Connect the MJS host power supply, data cable, various pipelines and drill bits, and connect the internal pressure sensor to the monitoring display. Make sure that the pressure is cleared to zero when the drill bit is unloaded. The pipeline connections are sealed to ensure that there is no air in the pipe;

[0030]Step 2: Ensure that the MJS main engine, high-pressure pump, air compressor, mud mixing system, and MJS management device are in normal working conditions, and the MJS main engine is in place, and the drill pipe length is zeroed after the rack is placed stably;

[0031]Step 3: Lower the drill rod with the drill bit in the pilot hole to the design depth. If it is difficult to lower the drill rod, turn on the cutting water for normal cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com