Push plate type clutch with heat-dissipating function

A push disc type clutch technology, applied in the field of clutches, can solve the problems of reducing the friction coefficient of metal discs and friction plates, the difficulty of high-power mechanical braking, and reducing the braking effect, so as to reduce the braking effect, prevent contact, increase The effect of braking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

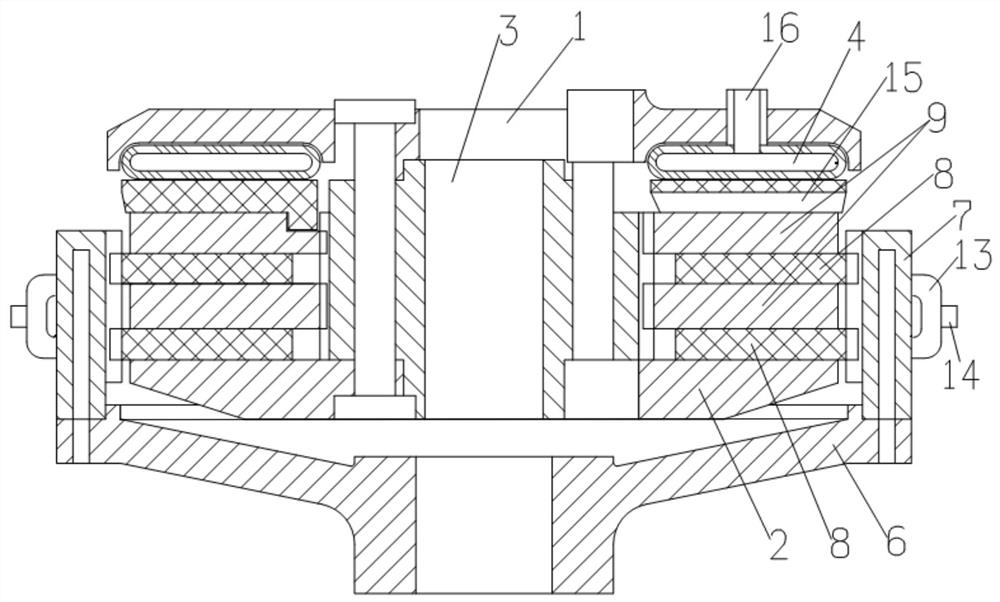

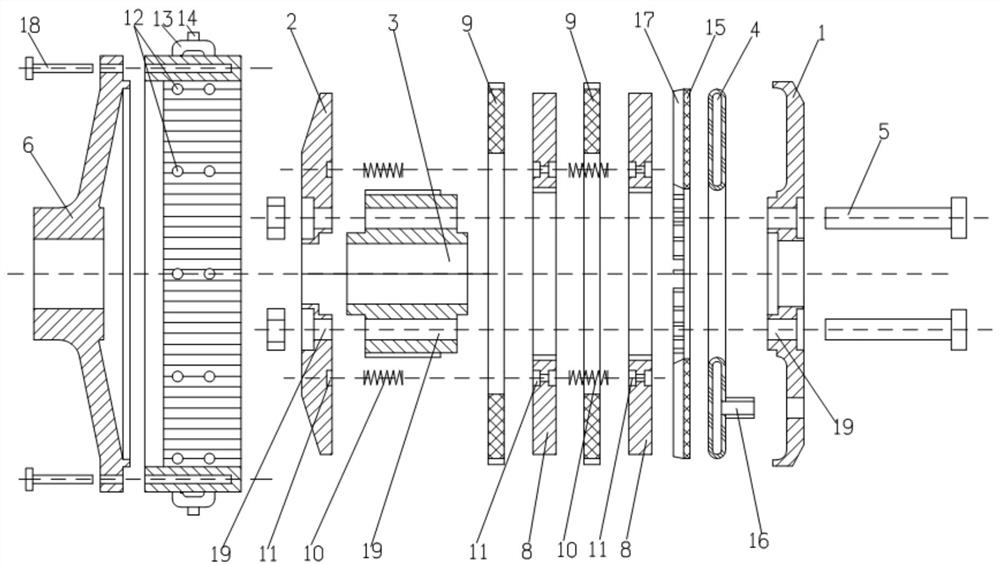

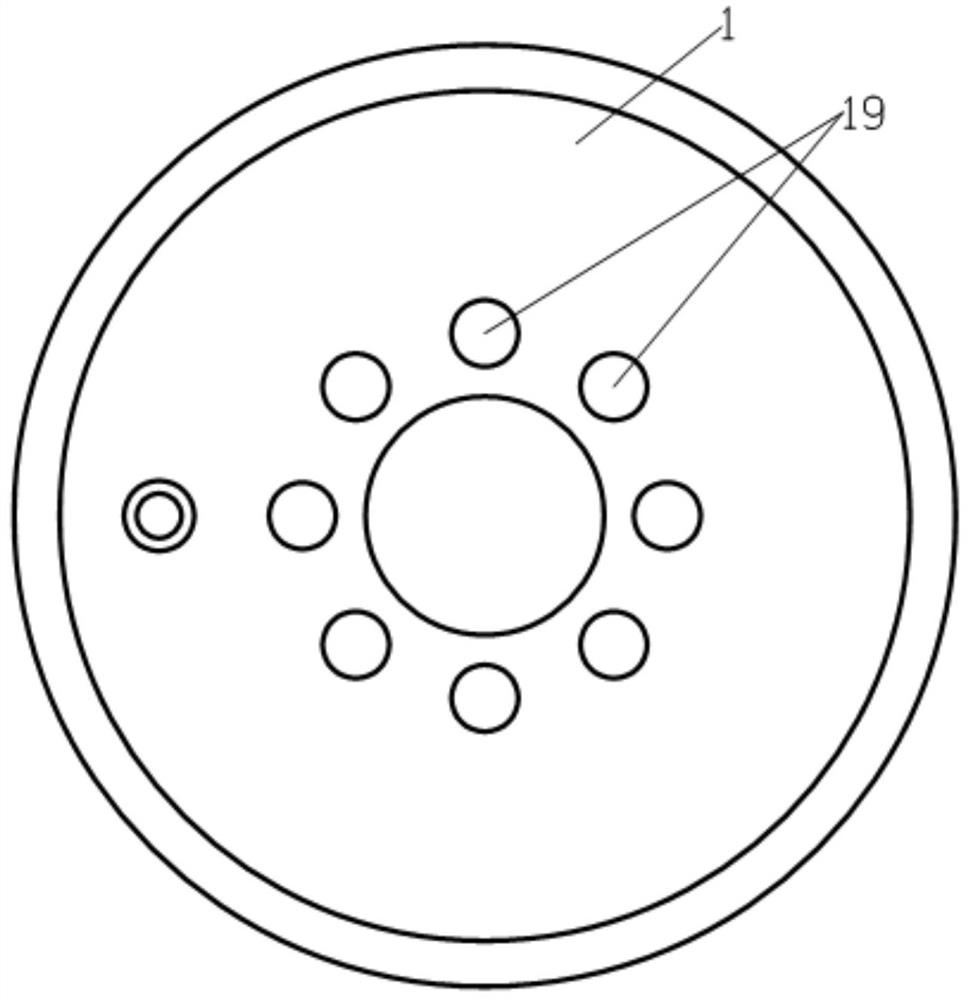

[0030] Example: see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 , in the figure, 1-upper fixed disc, 2-lower fixed disc, 3-driving ring gear, 4-airbag, 5-first fixing bolt, 6-fixing frame, 7-internal gear ring, 8-metal disc, 9 -Friction plate, 10-support spring, 11-counterbore, 12-ring baffle, 13-second counterbore, 14-second support spring, 15-backing plate, 16-air inlet, 17-bar convex Up, 18-the second fixing bolt, 19-through hole.

[0031] Push disc clutch with heat dissipation function, including fixed disc, fixed frame, air bag and clutch assembly. on the active ring gear, and fixed by the upper fixed plate and the first fixed bolt, the fixed frame is provided with an inner ring gear, and the inner ring gear is sleeved on the clutch assembly to realize the connection between the clutch assembly and the inner ring gear; the present invention uses the fixed plate , the fixing frame, the airbag and the clutch assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com