Integrated weighing sensor and electronic balance

A weighing sensor, integrated technology, applied in the detailed information of weighing equipment, weighing equipment and instruments using electromagnetic balance, etc., can solve the problems of low weighing accuracy, low manufacturing cost, slow response speed, etc. The effect of high weighing accuracy, low manufacturing cost and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

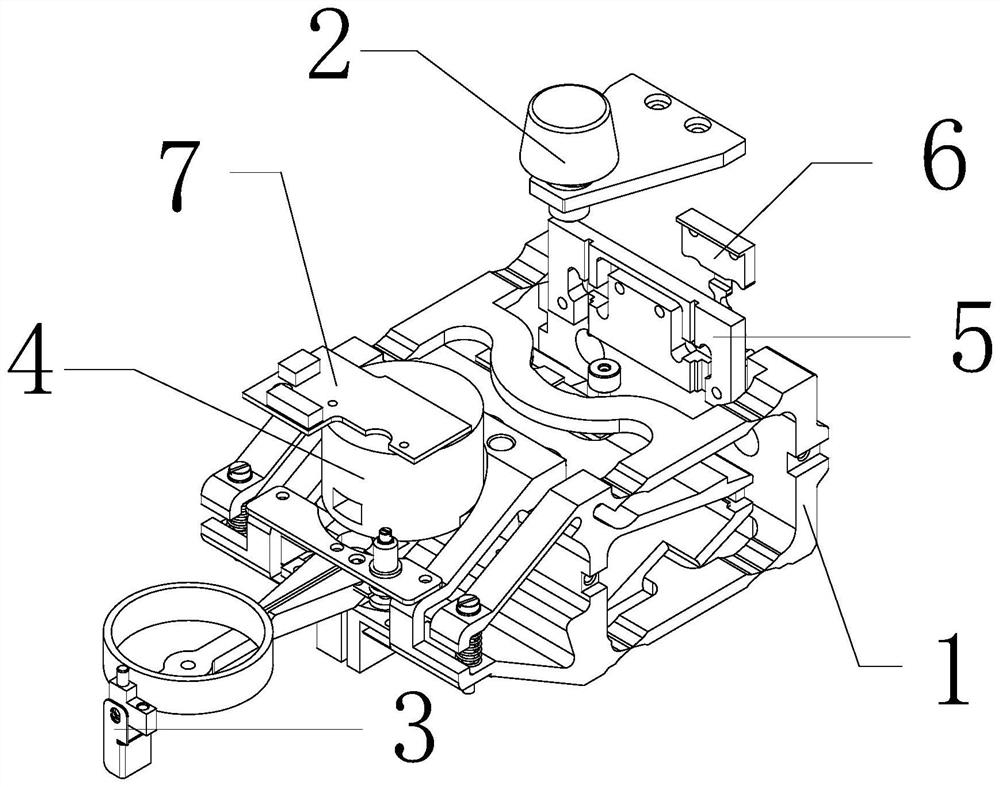

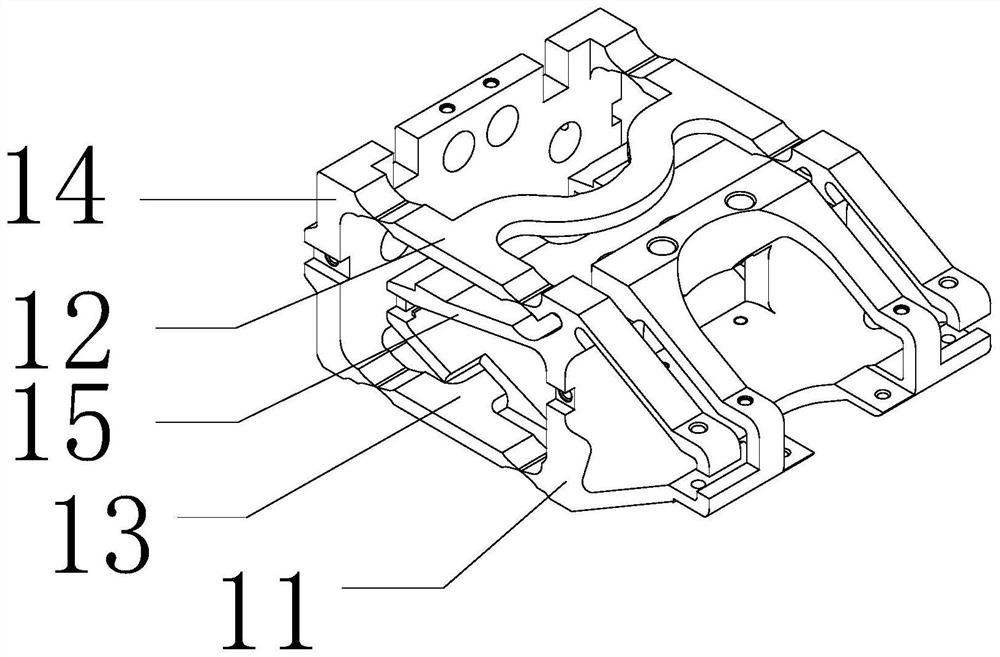

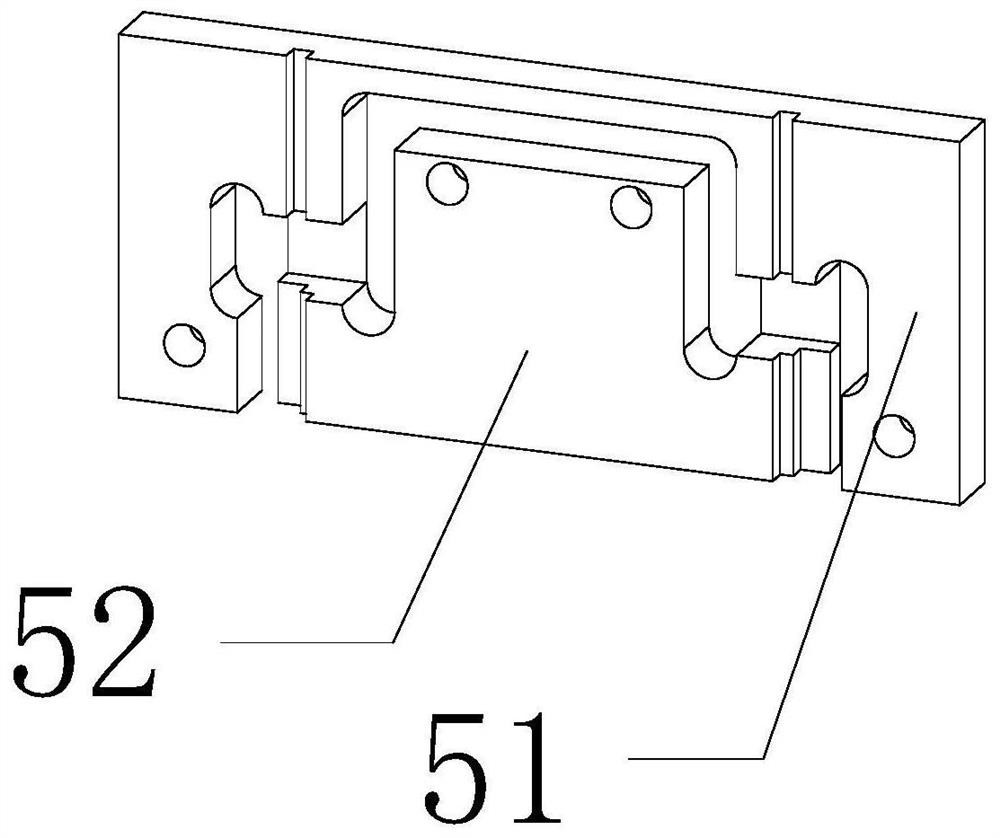

[0043] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, this embodiment provides an integrated weighing sensor, including an elastic body 1, a weighing pan-scale core assembly 2, a lever 3, a magnetic cylinder-coil assembly 4, a lever bracket 5 and a sling 6; the elastic body 1 includes The base 11, the upper parallel frame 12, the lower parallel frame 13, the load-bearing force measuring unit 14 and the lever support seat 15, the base 11, the upper parallel frame 12, the lower parallel frame 13, the load-bearing force measurement unit 14 and the lever support seat 15 are Integral structure, the elastic body 1 is designed as an open cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com