Test device and method for automobile power assembly

A technology of automobile powertrain and testing equipment, which is applied in vehicle testing, motor generator testing, machine/structural component testing, etc. It can solve the problems of large manpower input to motors, differences in test results of operating proficiency, and low efficiency. , to achieve the effect of meeting production needs, reducing labor input, and detecting accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

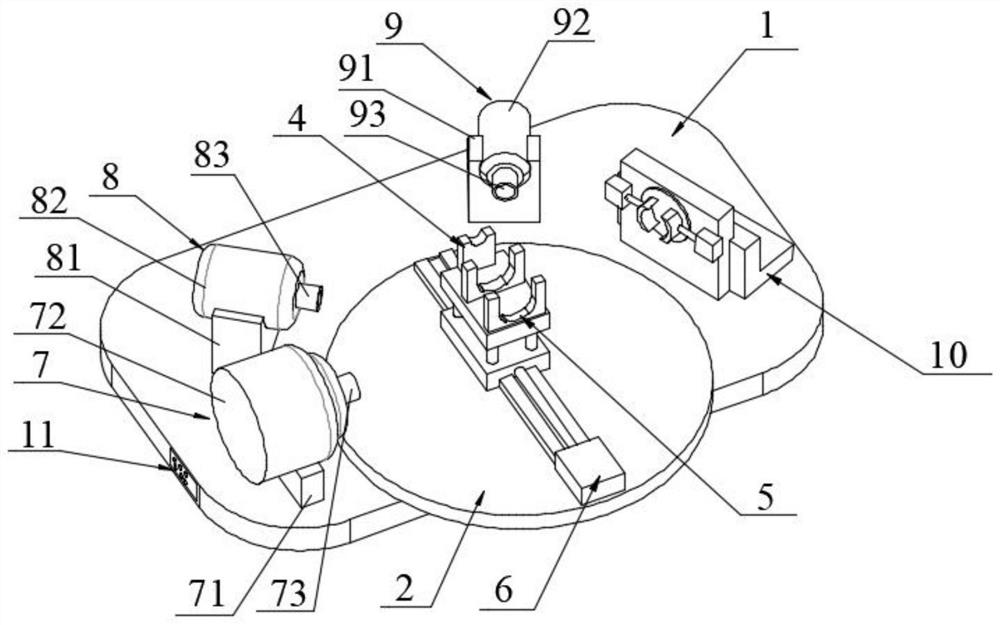

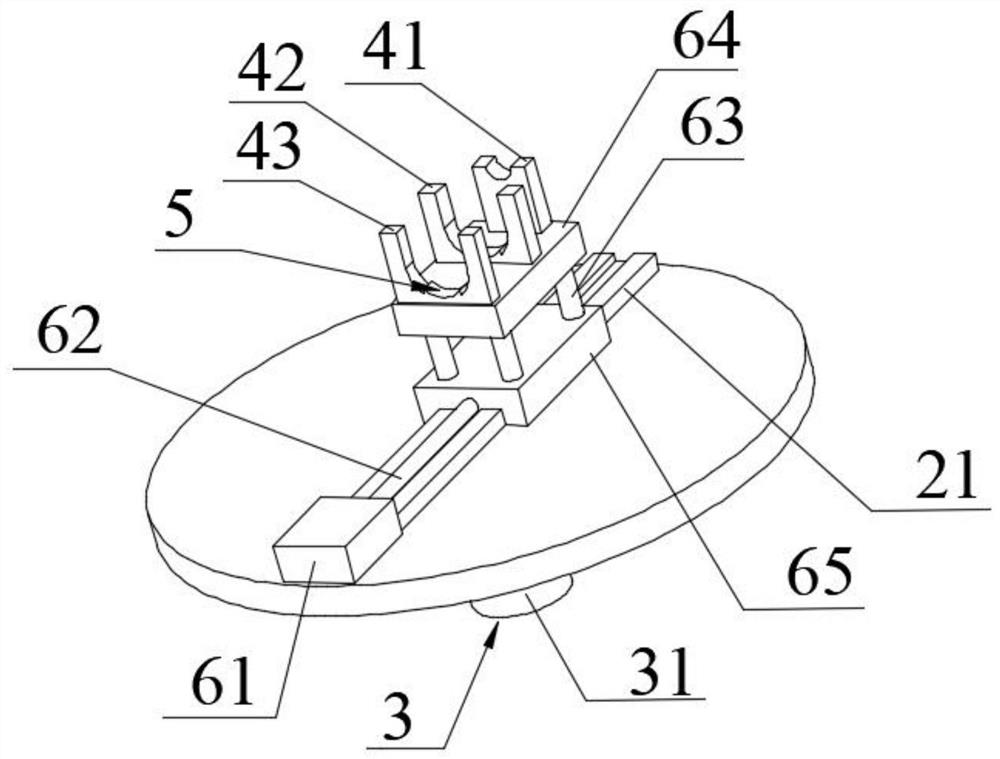

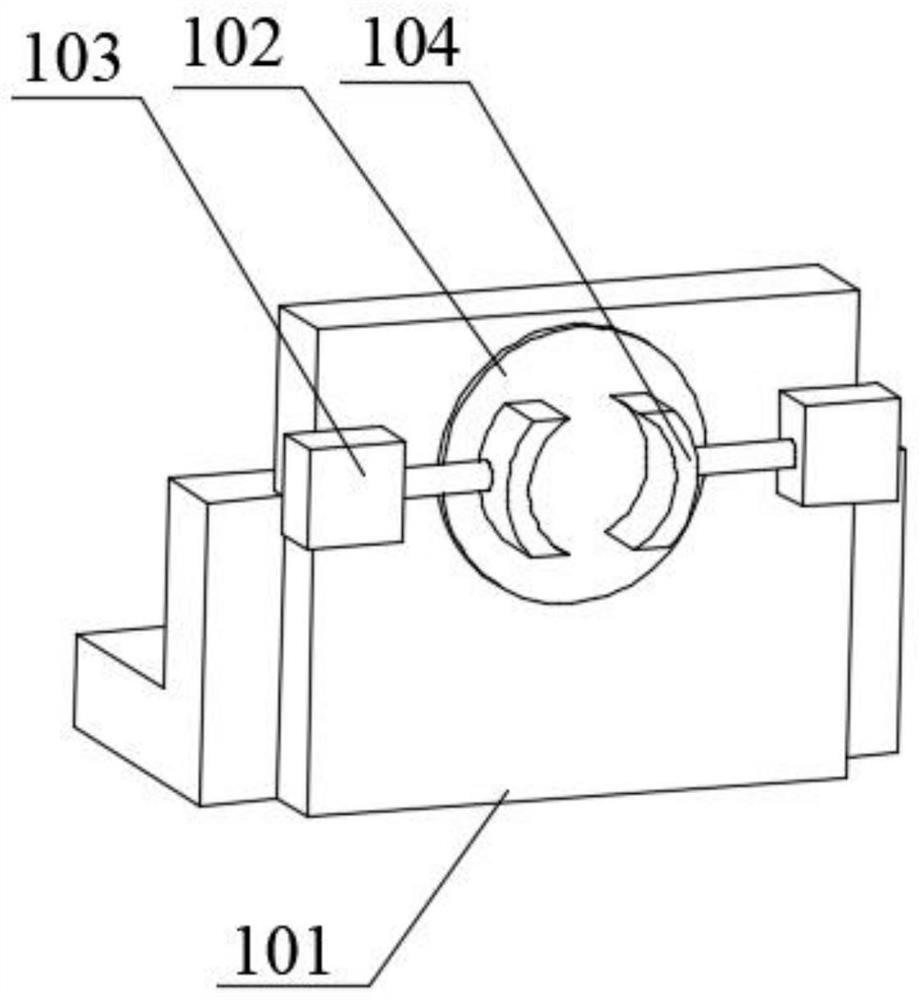

[0029] refer to figure 1 and figure 2 As shown, what the present embodiment provides is the test equipment and test method of automobile powertrain, including including machine table 1, the turntable 2 that is arranged on described machine table 1 and the turntable drive that is used to drive described turntable 2 to rotate intermittently Mechanism 3, a motor fixture 4 is arranged on the turntable 2, a vibration detection mechanism 5 arranged on the motor fixture 4, a fixture driving device 6 for driving the movement of the motor fixture 4 is arranged in turn around the turntable 2 The no-load detection mechanism 7, the load detection mechanism 8, the torque detection mechanism 9 and the locked-rotor torque detection mechanism 10, the machine table 1 side is provided with a controller 11, the turntable drive mechanism 3, the vibration detection mechanism 5, The clamp driving device 6 , the no-load detection mechanism 7 , the load detection mechanism 8 , the torque detection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com