Product defect online classification method in industrial visual inspection

A visual inspection and product defect technology, applied in the direction of optical testing flaws/defects, measuring devices, analyzing materials, etc., can solve the problems of insufficient classification accuracy, low classification efficiency, and low real-time performance, and achieve low space-time complexity and low error The effect of reducing the efficiency and reducing the computational complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing:

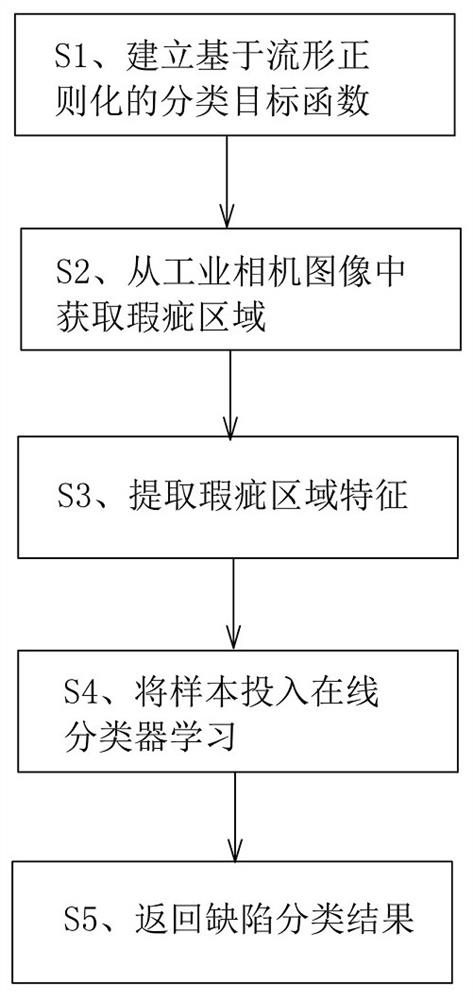

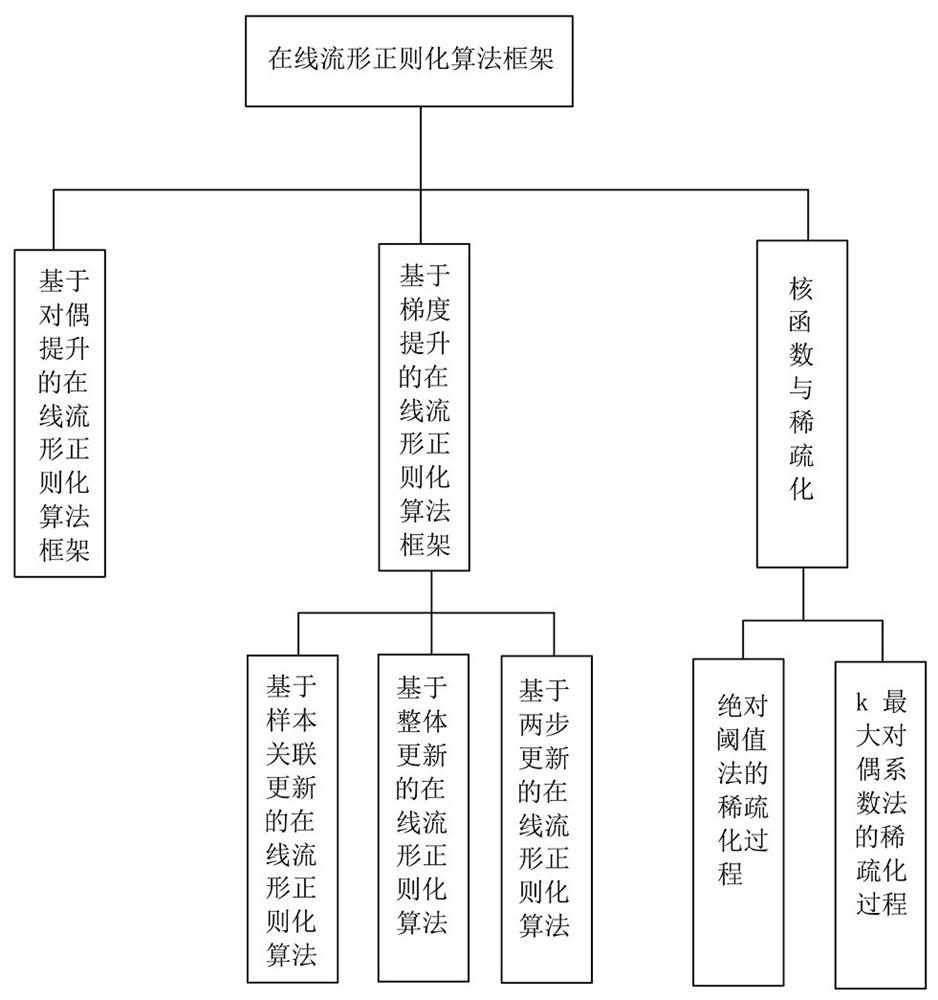

[0025] Such as Figure 1 to Figure 2 As shown, the technical scheme adopted by the present invention is as follows: a method for online classification of product defects in industrial visual inspection, comprising the following process steps:

[0026] S1. Establish a classification objective function based on manifold regularization: use the one vs the rest strategy to establish a classification objective function;

[0027] S2. Acquiring the defective area from the industrial camera image: after establishing the classification objective function in step S1, the blob analysis is used to obtain the defective area from the industrial camera image;

[0028] S3. Extracting defect area features: after the defect area is obtained in step S2, the features of the defect area are extracted using Blob analysis; the defect area features include area, length and width, average gray sca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com