Mechanical fault diagnosis method based on LOF-Kurtogram

A technology for fault diagnosis and rotating machinery, applied in the testing of mechanical parts, computer parts, and pattern recognition in signals, which can solve problems such as inability to accurately diagnose faults

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

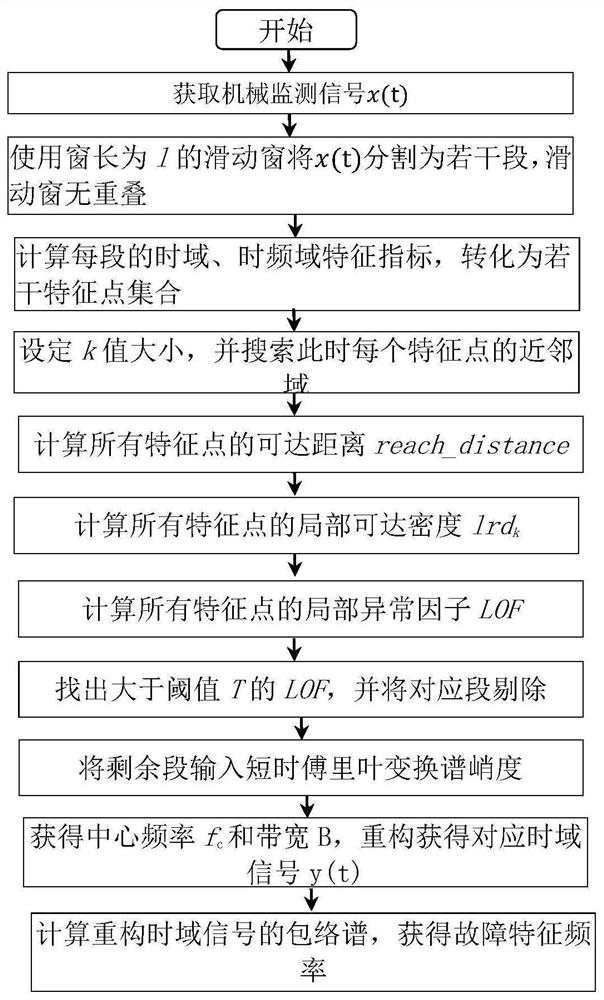

[0030] Such as figure 1 As shown, a method for abnormal segment detection of mechanical monitoring data based on kernel estimation LOF includes the following steps:

[0031] A LOF-Kurtogram-based fault diagnosis method for rotating machinery monitoring, comprising the following steps:

[0032] 1) Obtain a section of rotating machinery monitoring signal as the original signal x(t), where t=1,...,N, N is the number of sampling points of the section signal, using a sliding window with a window length of l, x(t ) is divided into several segments, and the number of segments is denoted as S;

[0033] 2) Extract time-domain features and time-frequency domain features for each segment to form a feature index set; where, middle f i Indicates the characteristic index vector of the i-th data segment during sliding, and the characteristic indexes include mean value,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com