Novel steel core ice melting insulated wire and ice melting system and method thereof

A technology of insulated wires and steel cores, applied in the direction of insulated conductors, insulated cables, conductors, etc., can solve the problems of limited application range, small equipment footprint, large capacity of ice-melting power supply, etc., to expand the scope of application and reduce ice-melting The effect of current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

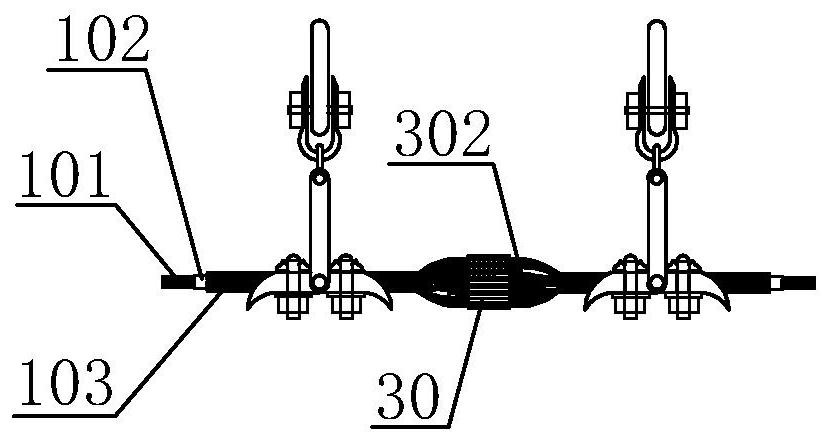

[0029] see figure 1 , this embodiment provides a new type of steel core ice-melting insulated wire, the new type of steel core ice-melting insulated wire includes a steel core 101, an outer layer of aluminum stranded wire 103 and an insulating wire between the steel core and the outer layer of aluminum stranded wire layer 102, the two ends of the steel core are electrically connected to the outer layer of aluminum strands.

[0030] Specifically, according to the laying of power grid lines, when the laying range is large, multiple wires need to be connected. In this embodiment, two adjacent wires are connected through intermediate joints 30, and the intermediate joints 30 respectively connect The two steel cores 101 and the aluminum stranded wires 103 are electrically connected, and the steel core 101 and the aluminum stranded wires 103 are insulated by crimping the insulating layer 302 . The specific structure can refer to the pre-twisted wire suspension clamp structure for OP...

Embodiment 2

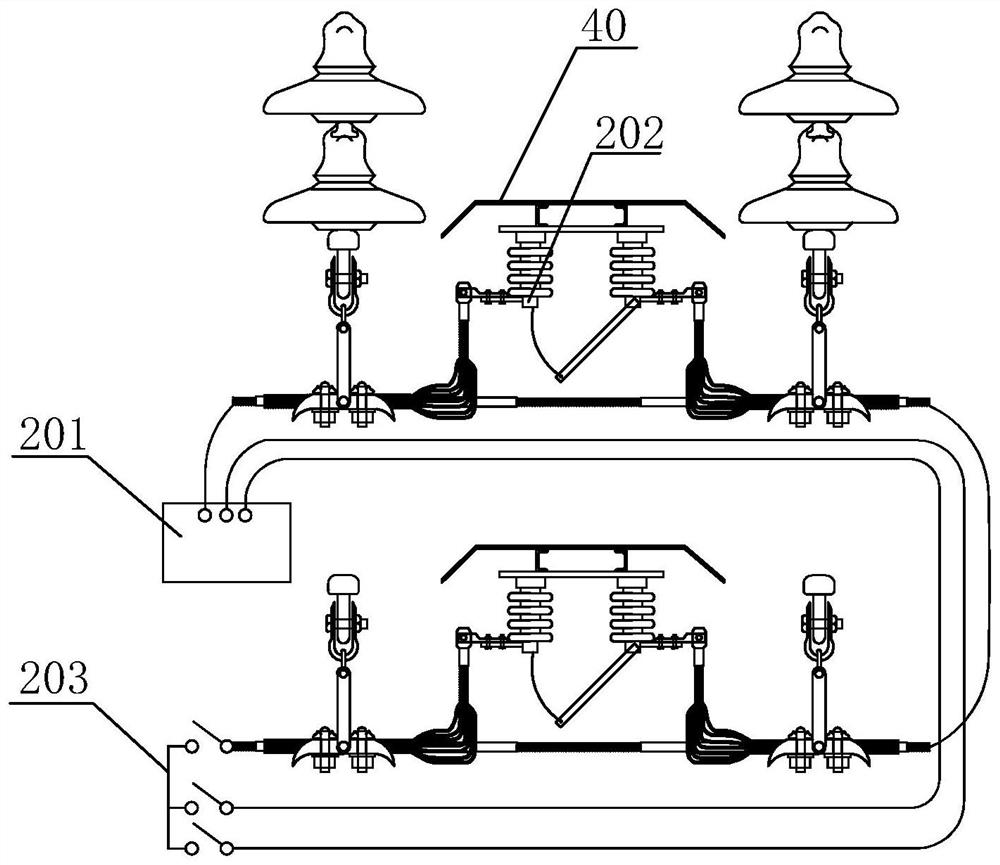

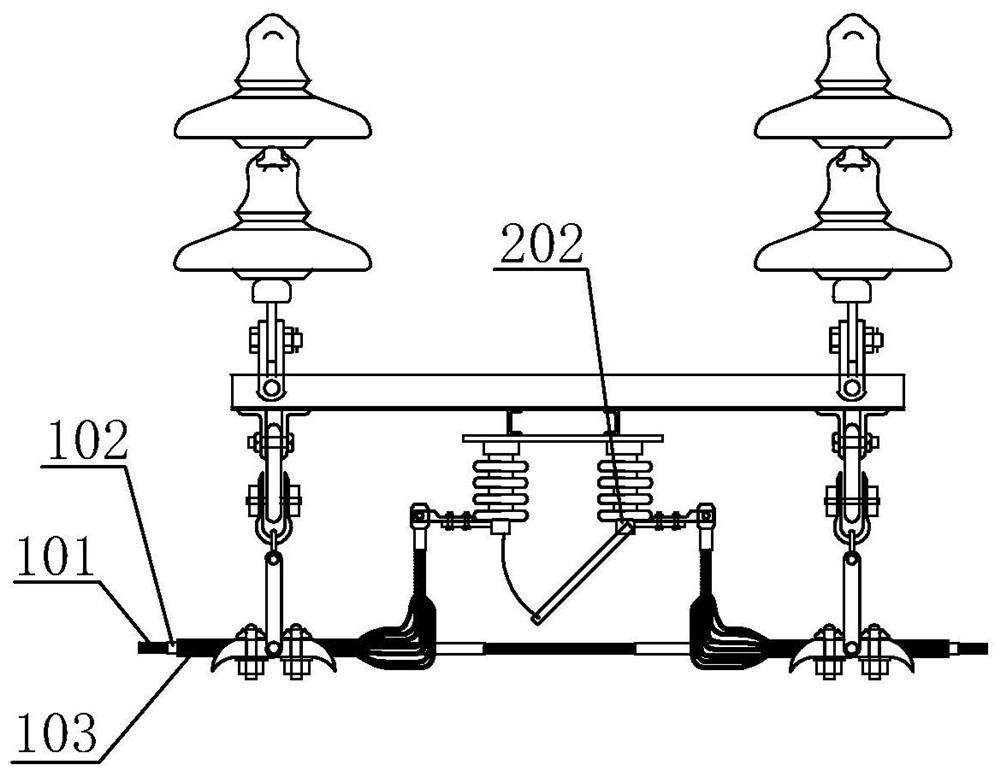

[0032] On the basis of Example 1, please refer to figure 2 and image 3 , the present embodiment provides a steel-core ice-melting insulated conductor ice-melting system, including an AC power supply 201, a steel-core insulation isolating switch 202 and a short-circuit knife switch 203, the aluminum strand of the conductor is disconnected, and the disconnection The steel core insulated isolating switch is connected, the short circuit switch is set at one end of the wire, and the AC power supply is connected to the other end of the wire.

[0033] Specifically, the steel core insulated isolating switch of this embodiment needs to be installed on the frame of the substation line outlet interval through insulators with the same insulation level as the line, or on a certain pole tower of the line. The line is equipotential, and it is at the floating potential when it is pulled apart, and the opening and closing operation is performed through the insulating rod.

[0034] Preferab...

Embodiment 3

[0037]On the basis of Embodiment 2, this embodiment provides an ice melting method of the ice melting system, specifically: when melting ice, open the steel core insulation isolating switch 202, close the short circuit knife switch 203, All the ice-melting currents from the AC power supply 201 flow through the steel core 101 to melt the ice.

[0038] Theoretical basis of the present invention:

[0039] According to the calculation formula of the melting current of the wire:

[0040]

[0041] In the formula: I r ——Icing current (A)

[0042] R 0 ——Wire resistance at 0°C (ohm / meter)

[0043] T r ——Icing time (hours)

[0044] Δt——the difference between the conductor temperature and the outside air temperature (°C)

[0045] g O ——The specific gravity of ice (generally 0.9 is taken as Yusong)

[0046] b—thickness of the ice layer, that is, the thickness of ice on each side of the ice (cm)

[0047] D——The outer diameter of the conductor after ice coating (cm)

[0048] R...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap