A kind of laminated soft pack metal-air battery and its preparation method

An air battery, metal technology, applied in the direction of secondary battery, secondary battery repair/maintenance, fuel cell type half cell and secondary battery type half cell, etc., can solve the energy density and specific energy of lithium-air battery Low battery cell contact deterioration, affecting the overall performance of the battery and other problems, to achieve large-scale industrial machine production, improve the energy density and specific energy of the monomer, and solve the effect of poor cell contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

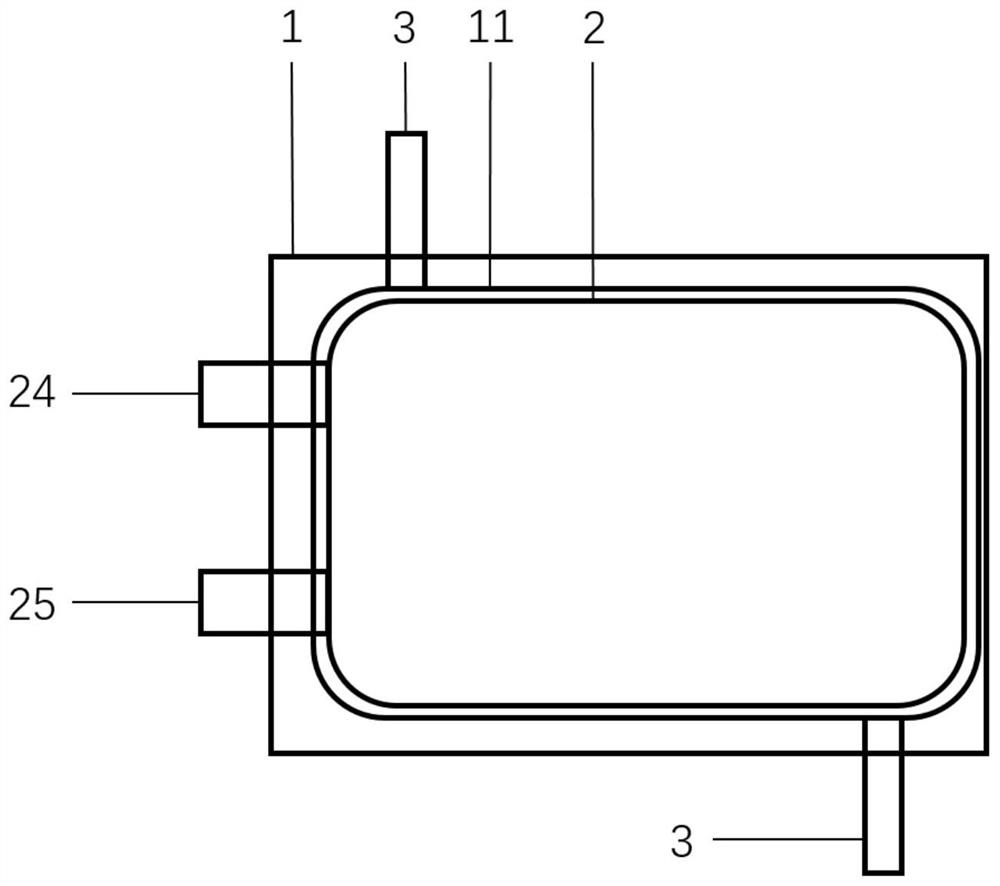

[0034] See figure 1 , a laminated type soft-clad metal-air battery of the present invention consists of a packaging shell 1, a battery cell tank 11 formed inside the packaging shell 1, a battery cell 2 arranged in the battery cell tank 11, an electrolyte, and an electrolytic Liquid injection and gas conduction device 3 composition.

[0035] The packaging shell 1 can be soft packaging film or metal hard shell, including but not limited to aluminum-plastic film, aluminum shell, stainless steel shell. The depth of the cell slot 11 is preferably 1-100 mm. In this embodiment, the packaging shell 1 is made of aluminum-plastic film with a size of 17.7cm*5.75cm; the size of the battery cell 11 is 8.35cm*4.75cm, the depth is 2mm, and the edge width is 0.5cm.

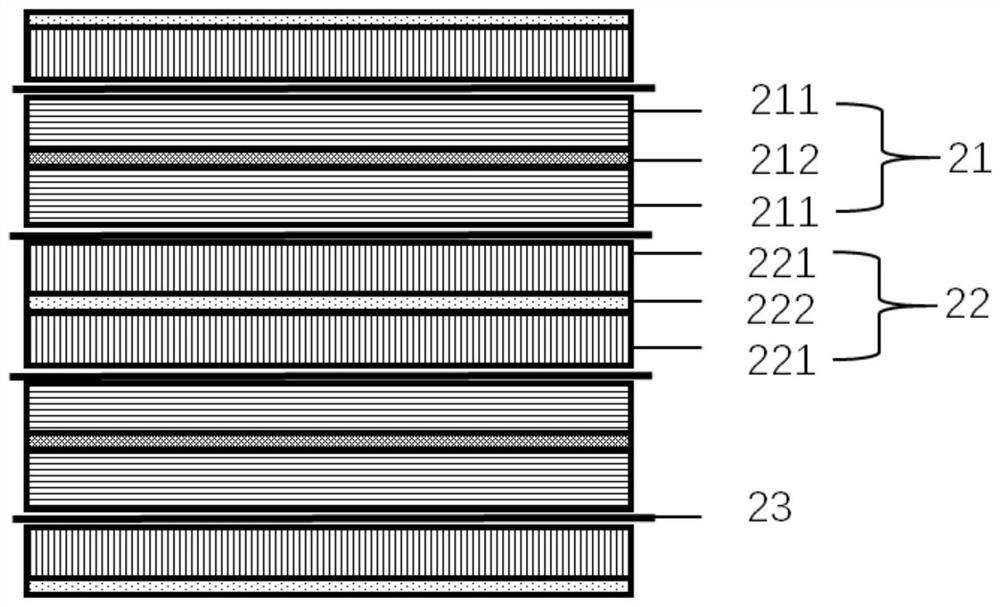

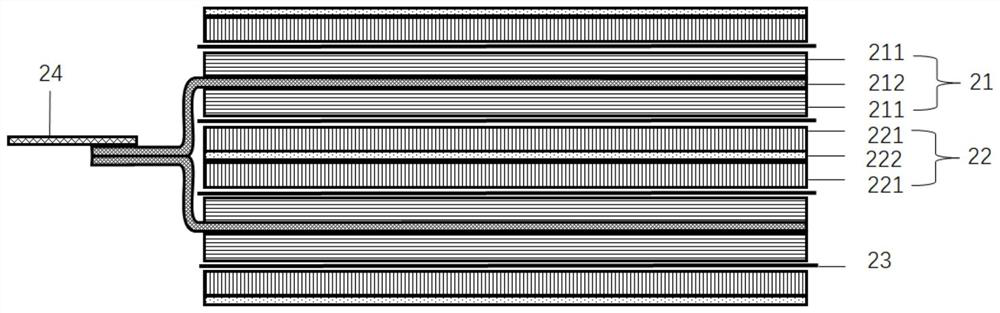

[0036] See Figure 2-4 The cell 2 includes a porous positive electrode sheet 21, a separator 23, a negative electrode sheet 22, a positive electrode ear 24 and a negative electrode ear 25, wherein the porous positive electrode...

Embodiment 2

[0046] Embodiment 2 is basically the same as Embodiment 1, the difference is:

[0047] The current collector of the porous positive electrode sheet is made of carbon paper, which is fixed with PET termination tape after being connected to the aluminum tab. The battery is discharged with a current of 10mA. Test results such as Image 6 As shown, the discharge capacity of the battery is 1313mAh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com