PWM signal generator circuit

A PWM signal and generator technology, applied in the direction of instruments, electrical components, adjusting electrical variables, etc., can solve the problems of large duty cycle, increase the complexity of the system, blow up the machine, etc., to reduce the PCBA area, save peripheral circuits, The effect of saving program cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Please refer to Figure 1 to Figure 5 , Embodiment 1 of the present invention is:

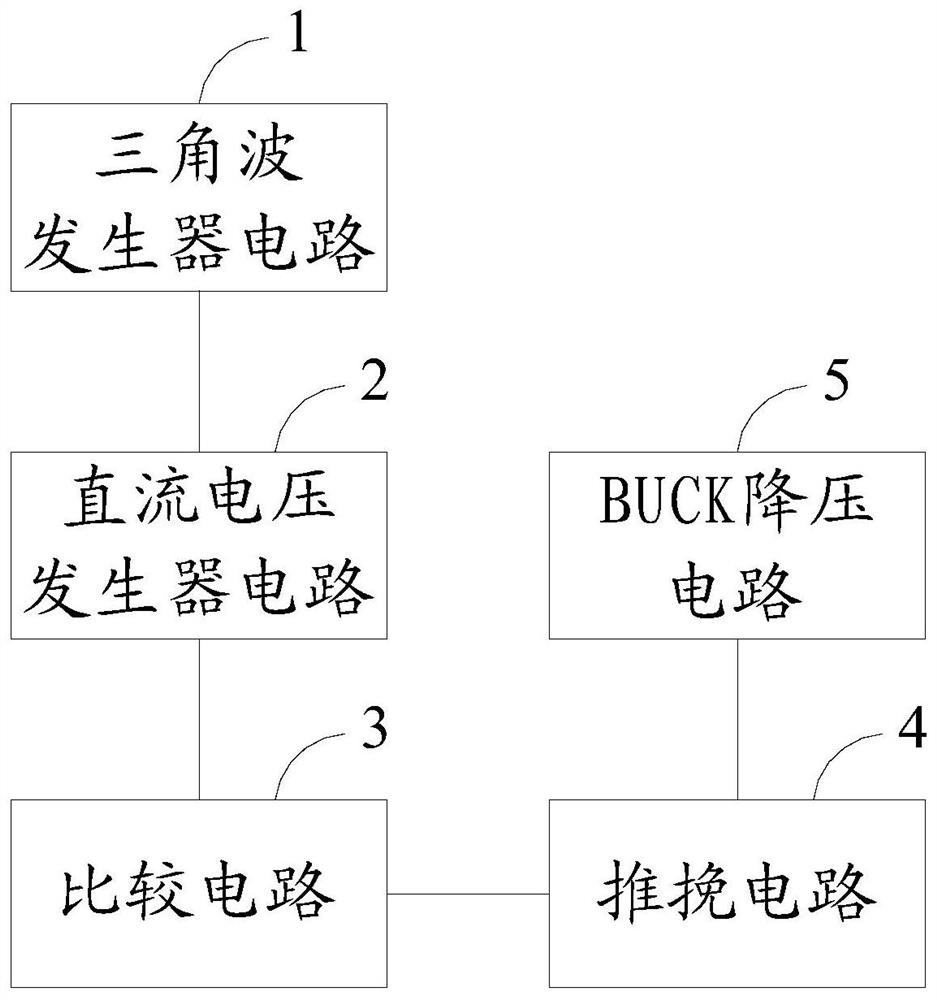

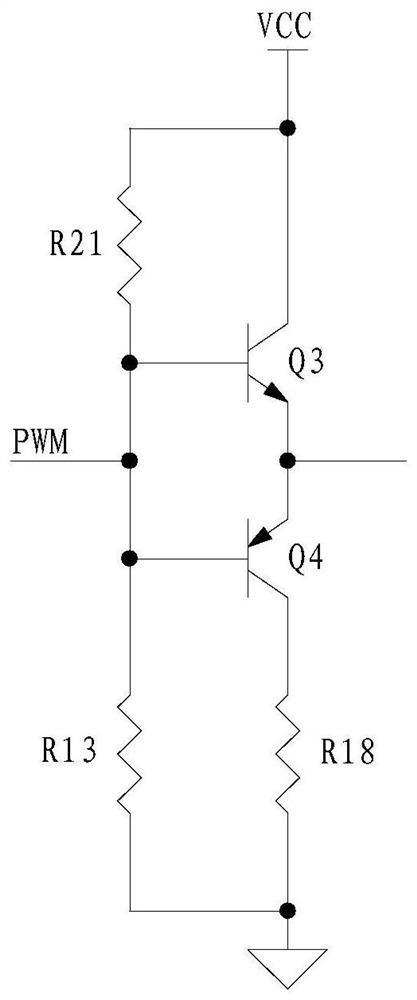

[0033] Please refer to figure 1 , a PWM signal generator circuit, comprising a triangle wave generator circuit 1, a DC voltage generator circuit 2 and a comparison circuit 3, the DC voltage generator circuit 2 is electrically connected to the triangle wave generator circuit 1 and the comparison circuit 3 respectively, the The comparison circuit 3 is electrically connected to the push-pull circuit 4 of the peripheral, and the push-pull circuit 4 is electrically connected to the BUCK step-down circuit 5 of the peripheral.

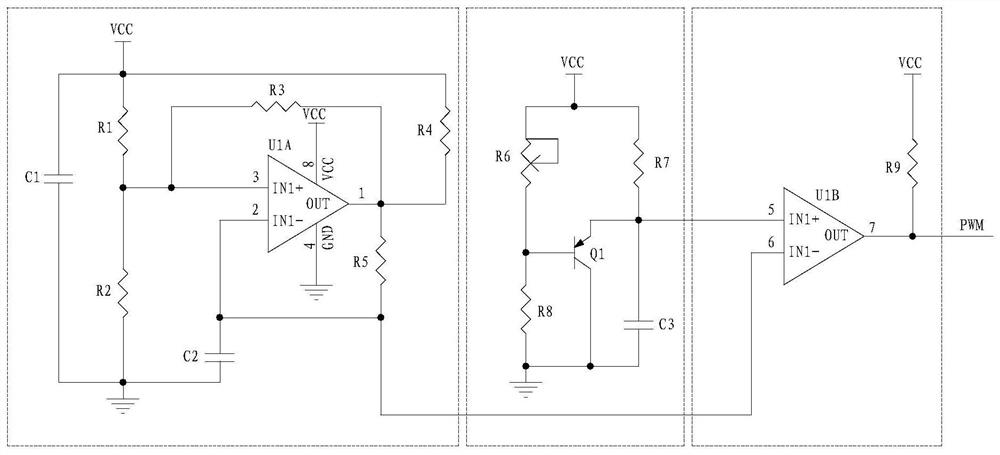

[0034] Please refer to figure 2 , the triangular wave generator circuit 1 includes resistor R1 (resistance value is 9.1kΩ), resistor R2 (resistance value is 9.1kΩ), resistor R3 (resistance value is 9.1kΩ), resistor R4 (resistance value is 9.1kΩ), resistor R5 (resistance value is 9.1kΩ), capacitor C1 (capacitance value is 0.1μF, voltage value is 50V), capacitor C2 (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com