Impact ionisation spray or electrospray ionisation ion source

A technology of electrospray ionization and ion source, which is applied in the field of ion mobility spectrometer and mass spectrometer, and can solve the problems of not using it

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

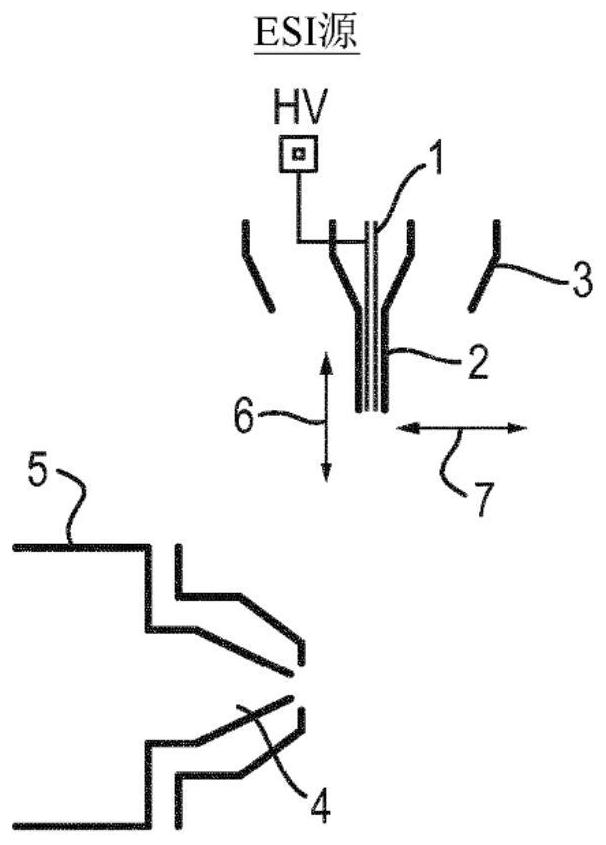

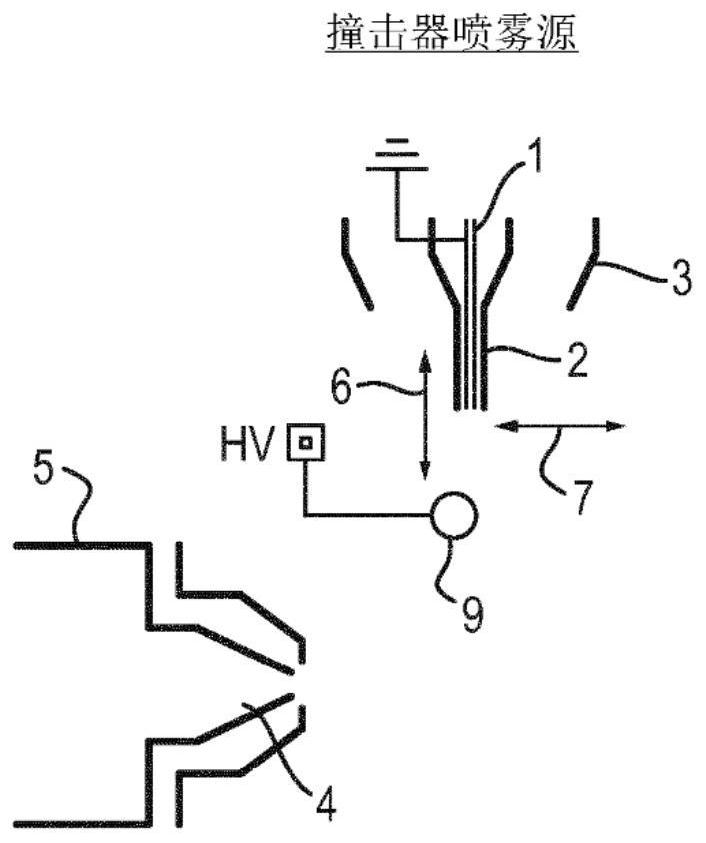

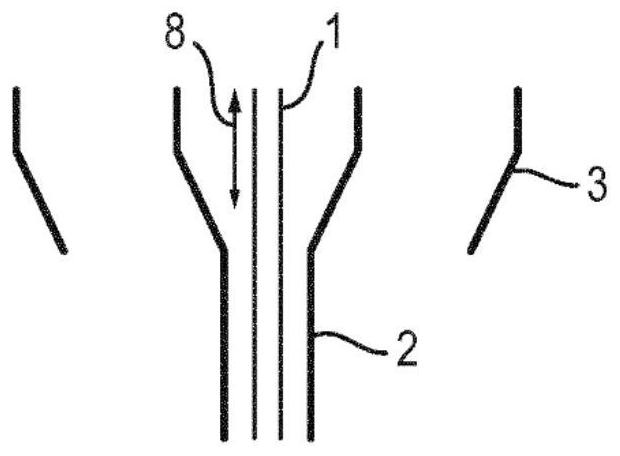

[0082] Figures 1A-1C illustrate typical electrospray ionization ion sources and impactor spray ionization ion sources for use in liquid chromatography / mass spectrometry (LC / MS) systems.

[0083] Figure 1 shows a typical electrospray ionization ion source. In the electrospray ionization ion source of FIG. 1 , the nebulizer is constructed by an inner liquid conduit 1 and an outer atomizing gas conduit 2 . Both conduits are constructed of stainless steel. In this example, the liquid conduit 1 has an inner diameter of 130 μm and an outer diameter of 230 μm. In this example, the inner diameter of the gas conduit 2 is 330 μm.

[0084] In operation, liquid flows into the liquid conduit 1 at a rate typically in the range of 10 μL / min to 2 mL / min. Gas line 2 was pressurized to 100 psi with nitrogen to generate a high velocity nebulizer gas flow of typically 200 L / hr. To heat the charged droplets of the nebulized sample, a second flow of nitrogen gas (1000 L / min) was passed between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com