Automatic cleaning ore crusher based on 5G technology

An automatic cleaning and pulverizer technology, which is applied to the cleaning method using liquid, mechanical equipment, vibration suppression adjustment, etc., can solve the problems of polluting the working environment and surrounding ecological environment, wasting water resources, and inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

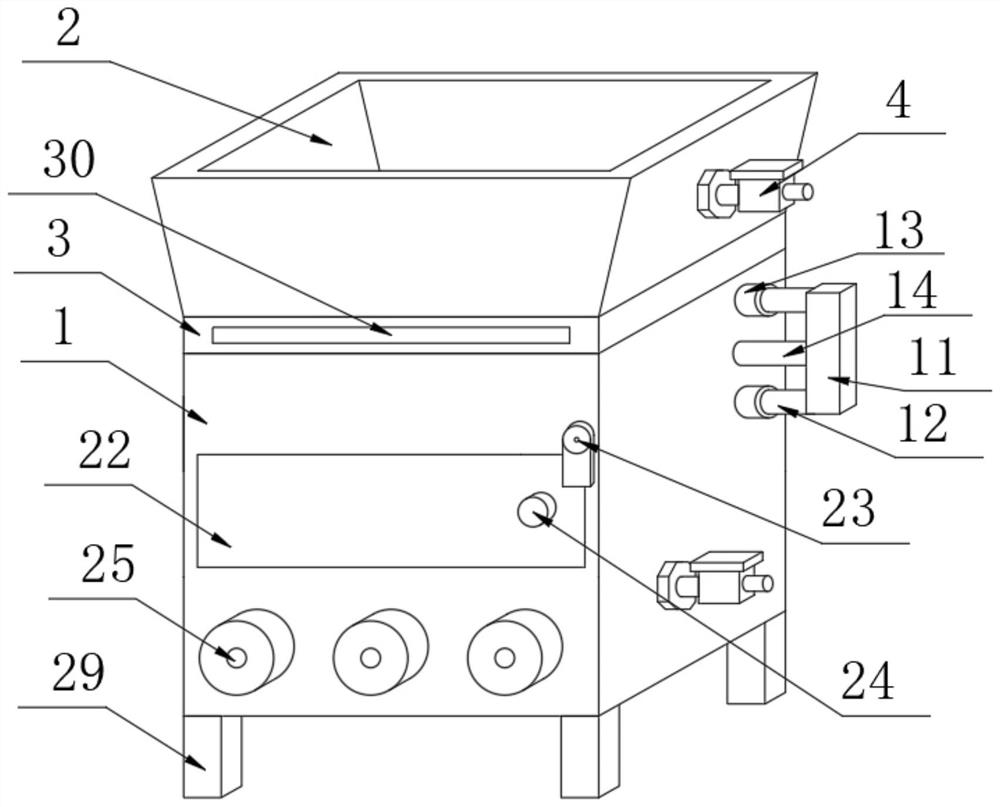

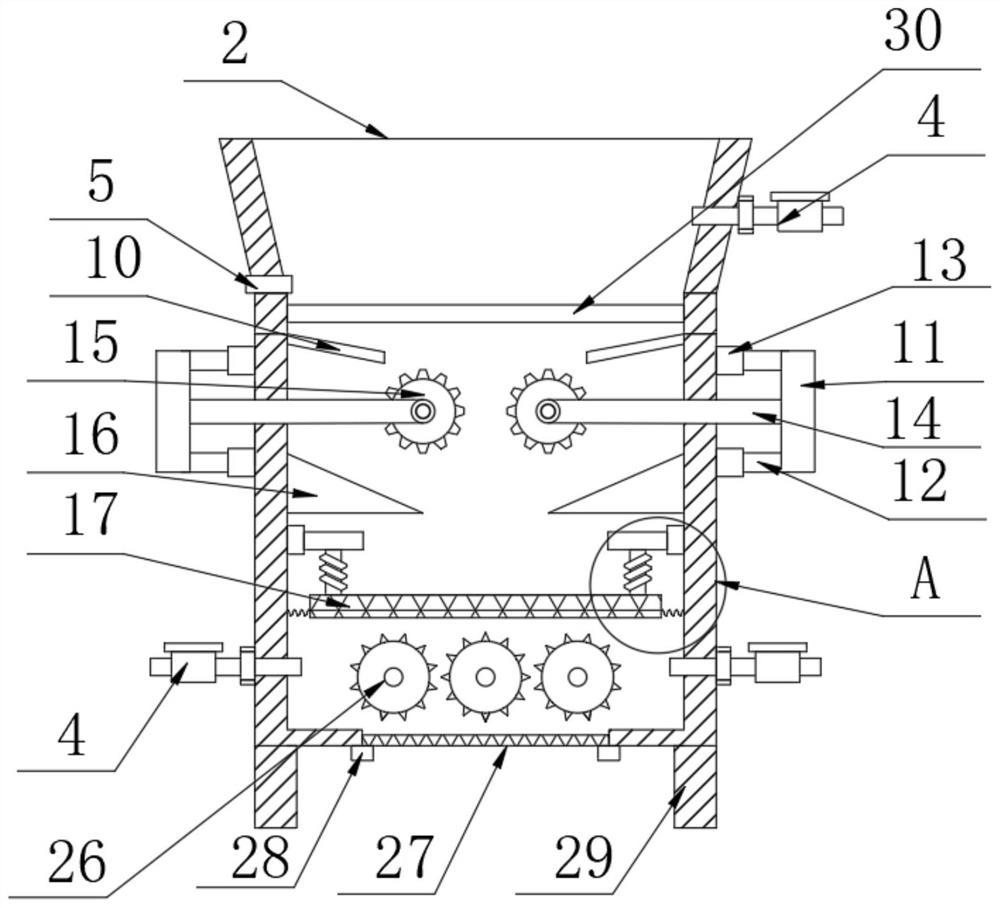

[0028] refer to Figure 1-5 , an automatic cleaning ore pulverizer based on 5G technology, including a body 1, a connecting block 3 is arranged above the body 1, a feeding bin 2 is arranged above the connecting block 3, and a water spray mechanism 4 is arranged on one side of the feeding bin 2, The bottom end of the other side of the feed bin 2 is provided with a water outlet 5, and the water outlet 5 communicates with the inside of the feed bin 2. Three motors 25 are horizontally arranged on the front of the body 1, and a water spray mechanism 4 is arranged on both sides of the body 1. The body 1 There is a first baffle 10 inside, a first crushing roller 15 is arranged under the first baffle 10, a second baffle 16 is arranged under the first crushing roller 15, and a first sieve is arranged under the second baffle 16 17. Three second crushing rollers 26 are arranged horizontally below the first sieve plate 17. The rotating shaft of the second crushing rollers 26 is fixedly co...

Embodiment 2

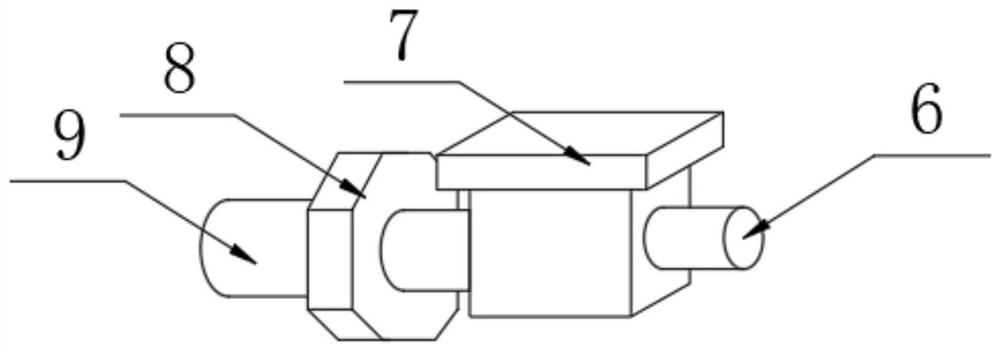

[0030]On the basis of Embodiment 1, as a further improvement, an electric door 30 is arranged symmetrically inside the connecting block 3 , chute 32 is arranged on both sides inside the connecting block 3 , and electric sliders 31 are arranged on both sides of the electric door 30 . 30 and the electric slider 31 are fixedly connected, and the electric slider 31 and the chute 32 are slidingly matched. The water spray mechanism 4 includes a water inlet pipe 6, a water pump 7, a water spray pipe 9 and a nut 8. One side of the water pump 7 is fixedly connected to the The water inlet pipe 6 and the other side of the water pump 7 are fixedly connected to the water spray pipe 9, the water spray pipe 9 is sleeved with a nut 8, and the water spray pipe 9 passes through the body 1 and communicates with the inside of the body 1. By setting the electric door 30, the chute 32 and the electric slider 31 inside the connection block 3, the electric door 30 can be closed when the feeding bin 2 ...

Embodiment 3

[0032] On the basis of Embodiment 1, as a further improvement, both sides of the body 1 are provided with mounting blocks 11, one side of the mounting block 11 is symmetrically provided with an electric telescopic rod 12, and one end of the electric telescopic rod 12 is fixedly provided with a fixed block 13, One side of the fixed block 13 is fixedly connected to the body 1, and the middle part of one side of the installation block 11 is provided with a connecting rod 14. The connecting rod 14 passes through the body 1 and is fixedly connected with the rotating shaft of the first crushing roller 15. The two sides of the first sieve plate 17 Both are connected with a first spring 21, a second spring 18 is arranged above the first sieve plate 17, a vibration generator 19 is arranged above the second spring 18, and an elastic rubber block 20 is arranged on one side of the vibration generator 19, and the elastic rubber block 20 The other side is fixedly connected to the body 1 . B...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap