Crushing device for solid waste detection

A solid waste and pulverizing device technology, applied in grain processing, cleaning methods and utensils, fixed filter element filters, etc. liquid and other problems to achieve the effect of reducing the probability of secondary pollution, reducing the probability of tool damage, and thoroughly crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

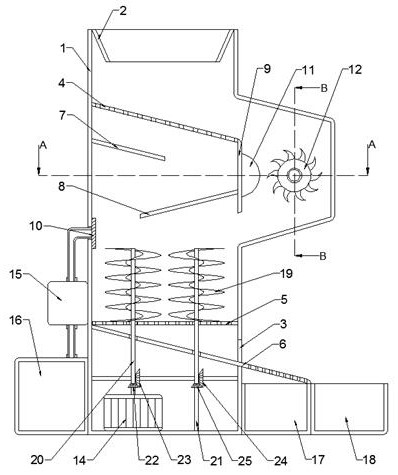

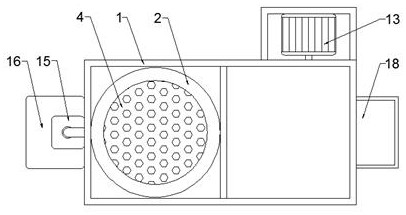

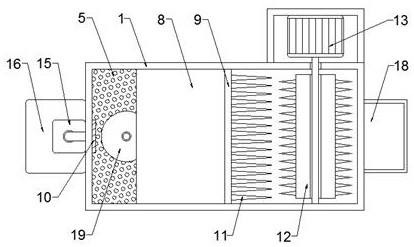

[0024] Embodiment: When the present invention is used, the solid waste to be pulverized is put into the feeding port 2, and when the solid waste falls on the first sieve plate 4, it will be screened once, and the smaller solid waste is directly fed from the first sieve plate 4. The sieve hole of the sieve plate 4 leaks down, falls into the working range of the spiral cutter 19 after being buffered by the first buffer plate 7 and the second buffer plate 8, and is thoroughly crushed. The first sieve plate 4 slides into the working range of the blade 11 and the knife roller 12. The first motor 13 drives the knife roller 12 to rotate. Pulverize, the solid waste that is preliminarily crushed falls along the gap between the blade 11 and the knife roller 12, and slides into the working range of the spiral cutter 19. When the second motor 14 is started, the second motor on the output shaft of the second motor 14 will A transmission gear 22 drives the first driven gear 23, and the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com