Assembly machine for buckle type bamboo summer sleeping mat

A snap-on, assembly machine technology, used in assembly machines, manufacturing tools, metal processing, etc., can solve the problems of high labor cost and low production efficiency, and achieve the goal of reducing defective product rework, reducing labor costs, and facilitating installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

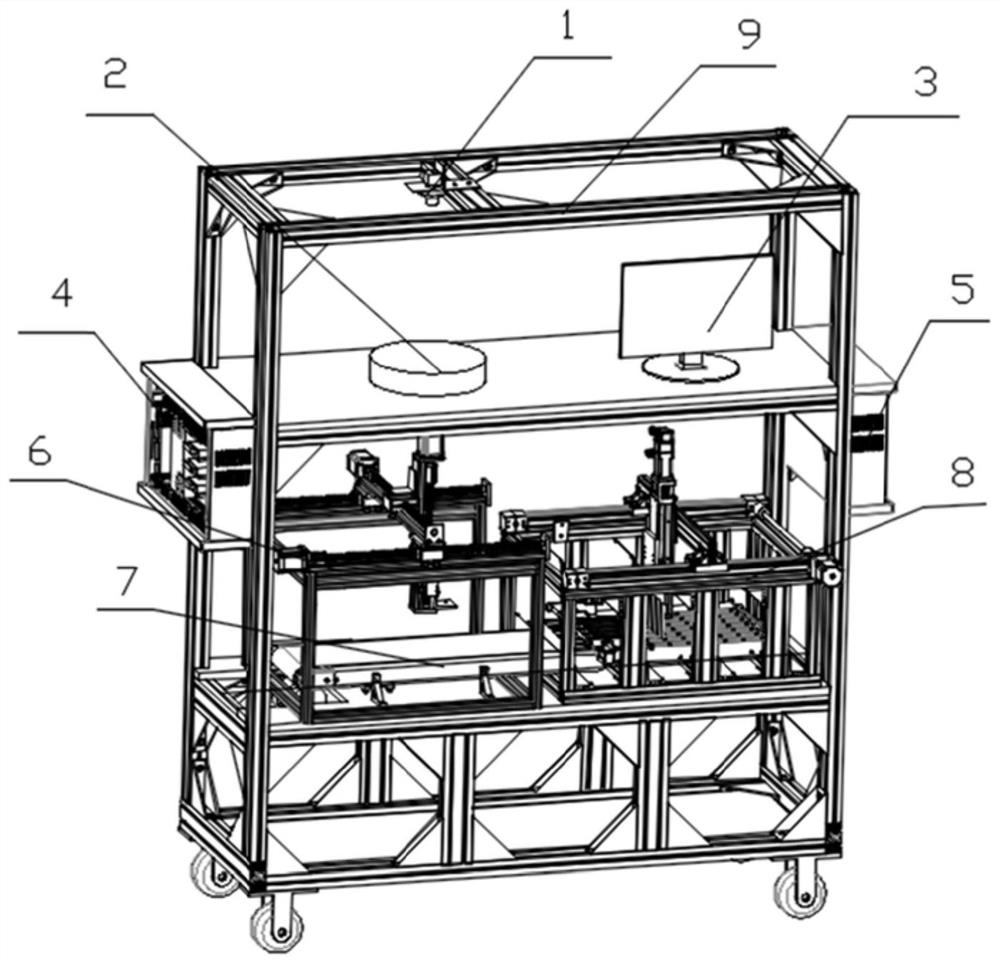

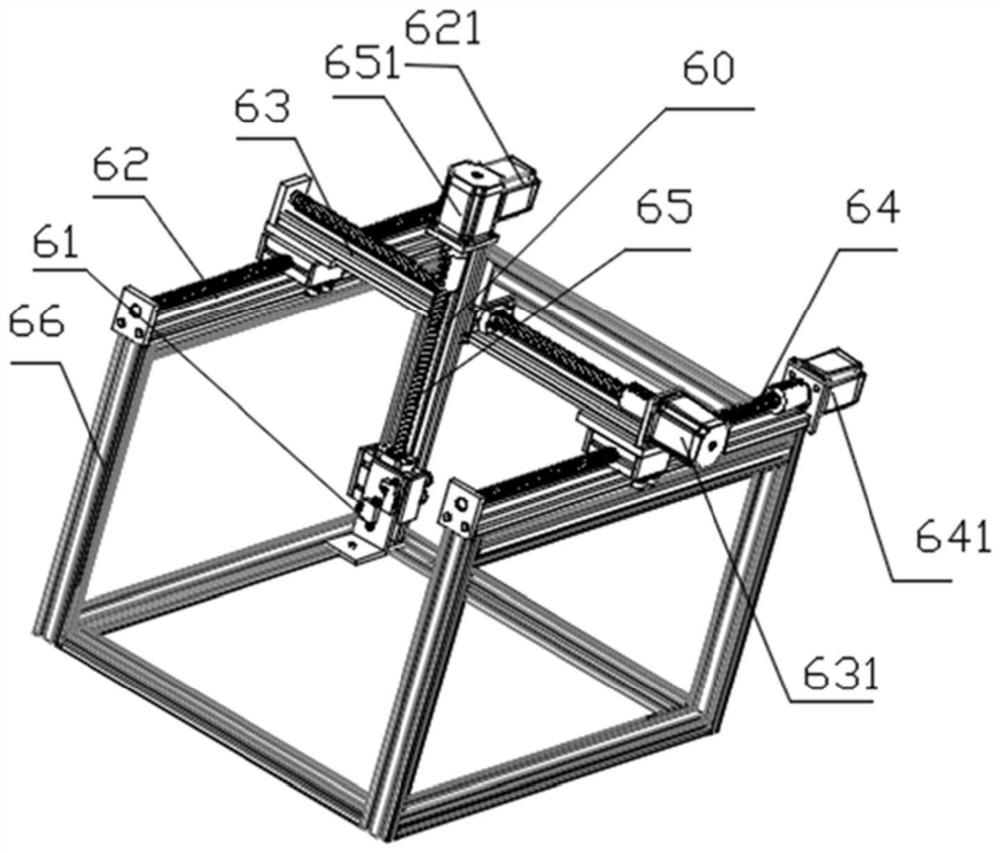

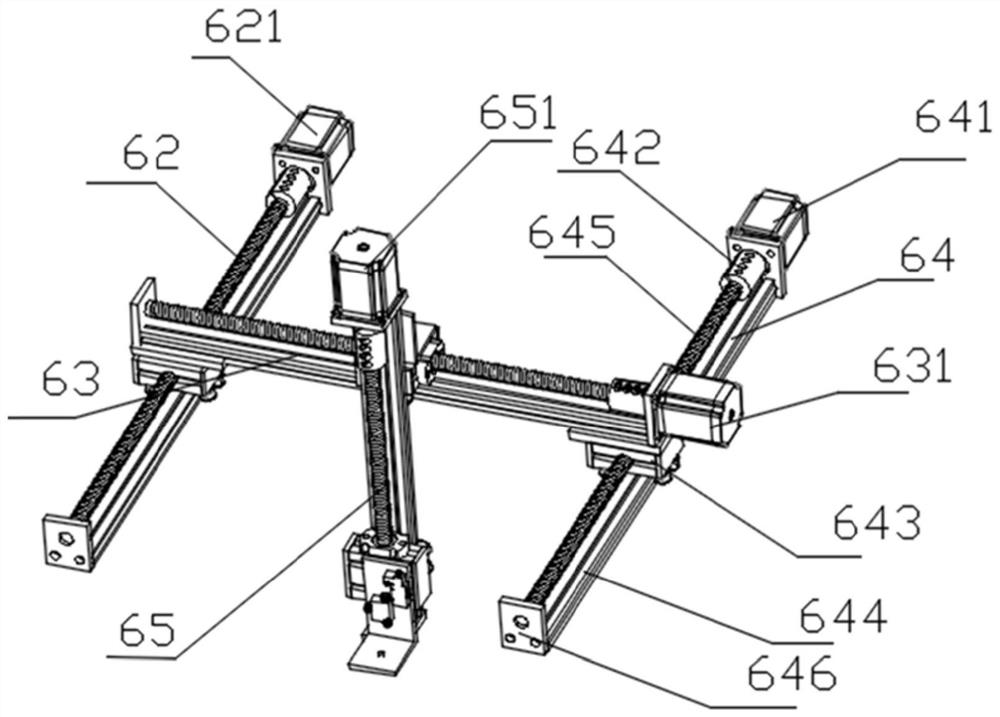

[0033] like figure 1 As shown, an assembly machine for snap-on bamboo mats includes an intelligent recognition module for parts, a control mechanism 6, a data processing mechanism 3, a conveying mechanism 7, an assembly mechanism 8, a controller and a main frame 9, and the main frame 9 includes an upper layer , the middle layer and the lower layer, the parts intelligent identification module and the data processing mechanism 3 are all installed on the upper layer of the main frame 9, the control mechanism 6, the conveying mechanism 7 and the assembly mechanism 8 are all installed on the middle layer of the main frame 9, and the controller is installed on the main frame 9 The lower layer (not shown in the figure), the parts intelligent identification module and the control mechanism 6 are all connected to the data processing mechanism 3, the conveying mechanism 7, the control mechanism 6 and the assembly mechanism 8 are all connected to the controller, and the feeding end of the...

Embodiment 2

[0057] In this embodiment, except the following technical characteristics, other technical characteristics are the same as those in Embodiment 1:

[0058] In this embodiment, the ABB multi-joint robot is installed in the control mechanism 6 and the assembly mechanism 8 instead of the XYZ coordinate system manipulator and the XZ coordinate system manipulator. The ABB multi-joint robot is more flexible and has higher precision.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com