Friction-free automobile hydraulic braking method and device

A technology of hydraulic braking and automobile braking, applied in hydraulic braking transmission, brakes, cooling brakes, etc., can solve the problems of fast wear and more friction and heat generation of automobiles, and achieve improved comfort, reduced vibration, and improved structure. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

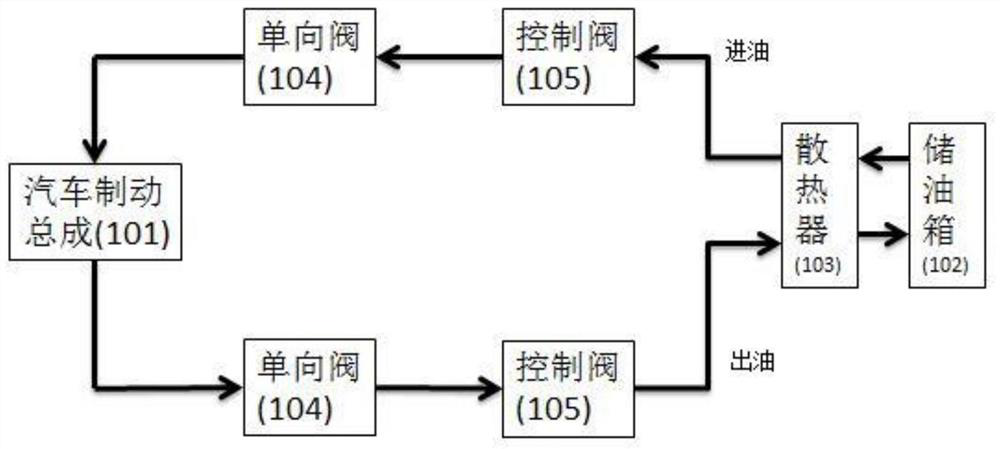

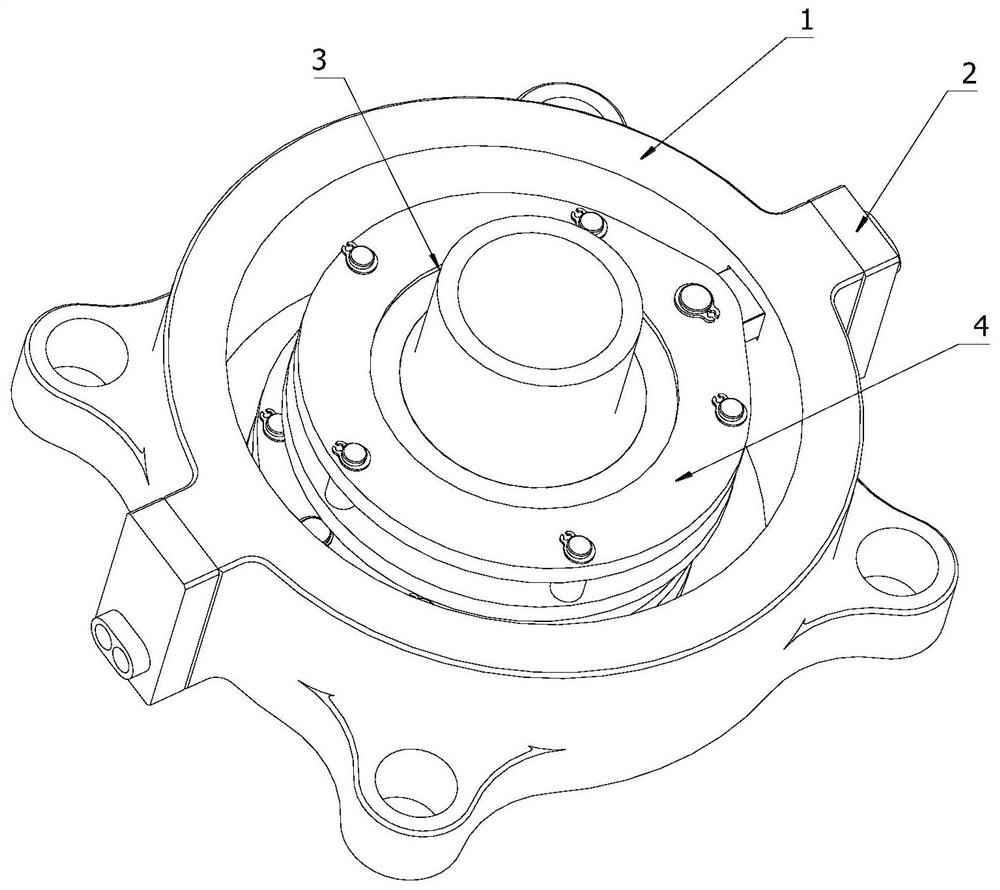

[0076] Such as Figure 2~4 , a frictionless automobile hydraulic braking method and device, comprising: an automobile brake assembly 101, an oil storage tank 102, a radiator 103, a one-way valve 104, and a control valve 105.

[0077] The automobile brake assembly 101 includes:

[0078] A box body 1, the box body 1 is fixedly arranged on the hub of the automobile;

[0079] Cylinder head 2, the cylinder head 2 is provided with two oil passage ports, which are the flow channels of the medium liquid, and the cylinder head 2 is fixedly arranged on the box body 1;

[0080] A hub coupling 3, the hub coupling 3 is fixedly arranged on the hub of the automobile;

[0081] Further, two eccentric circles are processed on the hub coupling 3, and the eccentric circles are distributed on both sides of the axis for rotationally connecting the eccentric braking ring 4;

[0082] An eccentric brake ring 4, the eccentric brake ring 4 is rotatably arranged on the hub coupling 3;

[0083] Furthe...

Embodiment 2

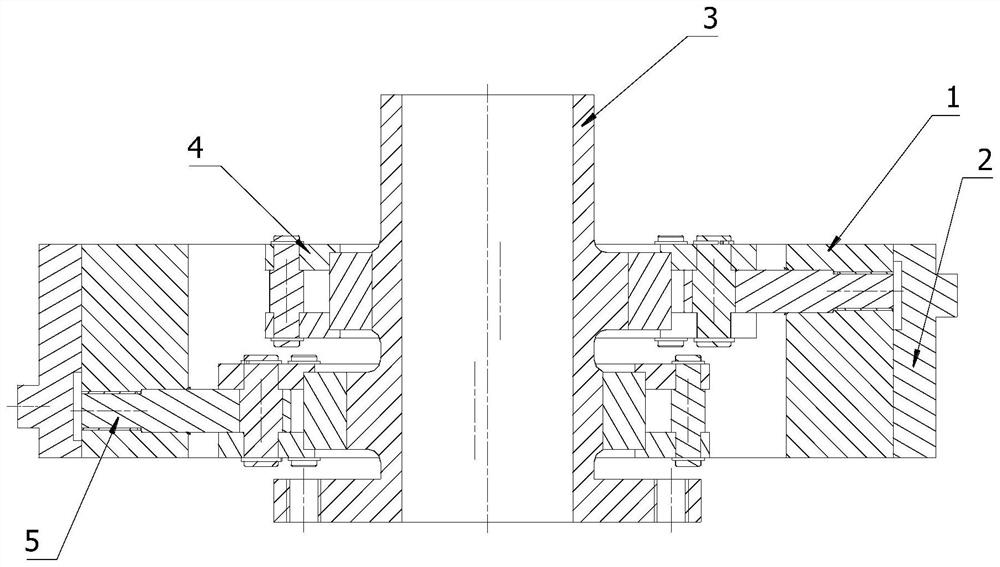

[0090] Such as Figure 5-8 As shown, a frictionless automobile hydraulic braking method and device includes: automobile brake assembly 101 , oil storage tank 102 , radiator 103 , one-way valve 104 , and control valve 105 .

[0091] The automobile brake assembly 101 includes:

[0092] A box body 1, the box body 1 is fixedly arranged on the automobile suspension;

[0093] Cylinder head 2, the cylinder head 2 is provided with several oil passage ports, which are the flow channels of the medium liquid, and the cylinder head 2 is fixedly arranged on the box body 1;

[0094] Hub coupling 3, the hub coupling 3 is fixedly connected with the automobile hub;

[0095] Further, two eccentric circles are processed on the hub coupling 3, and the eccentric circles are distributed on both sides of the axis for rotationally connecting the eccentric braking ring 4;

[0096] An eccentric braking ring 4, which is rotatably connected to the hub coupling 3;

[0097] Further, the eccentric braki...

Embodiment 3

[0106] Such as Figures 9 to 11 As shown, a frictionless automobile hydraulic braking method and device includes: automobile brake assembly 101 , oil storage tank 102 , radiator 103 , one-way valve 104 , and control valve 105 .

[0107] Described automobile braking assembly 101 comprises:

[0108] A box body 1, the box body 1 is fixedly arranged on the automobile suspension;

[0109] Cylinder head 2, the cylinder head 2 is fixedly arranged on the box body 1, and several oil passage ports are arranged on the cylinder head 2, which are the flow channels of the medium liquid;

[0110] A hub coupling 3, the hub coupling 3 is fixedly arranged on the hub of the automobile;

[0111] Further, the hub coupling 3 is processed with four supporting columns, two of which are hydraulic rotating supporting columns, with specially set oil passages inside, the eccentric oil cylinder 8 is rotated and set on the rotating hydraulic supporting columns, and the other two supporting columns It is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com