A kind of preparation method of reactive dye blue

A technology of reactive dyes and compounds, applied in the field of dyes, can solve problems such as unfavorable energy saving, emission reduction and clean production, affecting product quality and efficiency, color pattern and cylinder difference, etc., to achieve good color fixing ability, high reactivity, The effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

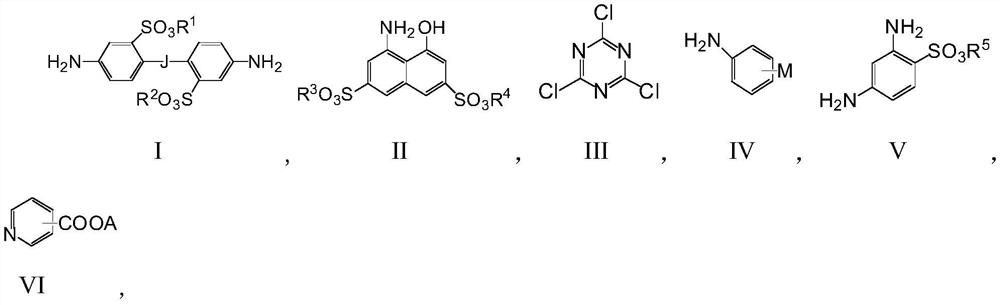

Method used

Image

Examples

Embodiment 1

(5) hydrochloric acid and sodium nitrite are added in the 4th mixed solution that step (4) obtains, react 1.5 hours at 0-5 ℃

When obtaining the fifth mixed solution, wherein, the molar ratio of HCl and sodium nitrite is 1:2.0:1.0;

(6) the second mixed solution that step (2) obtains is added in the fifth mixed solution that step (5) obtains, adds hydrogen carbonate

Sodium adjusts the pH value to 6.0-6.5, reacts at 10-15°C for 3.5 hours to obtain the sixth mixed solution, the second mixed solution and the fifth

The mixed solution feeding is 1:1.03 according to the molar ratio of feeding;

(7) will add in the 6th mixed solution that step (6) obtains, add sodium carbonate and adjust pH value to 5.5~

6.0, react at 75~80 ℃ for 7 hours to obtain the seventh mixed solution, wherein, with the molar ratio of feeding

1:2.5;

(8) the seventh mixed solution obtained in step (7) is dried to obtain product reactive dye blue.

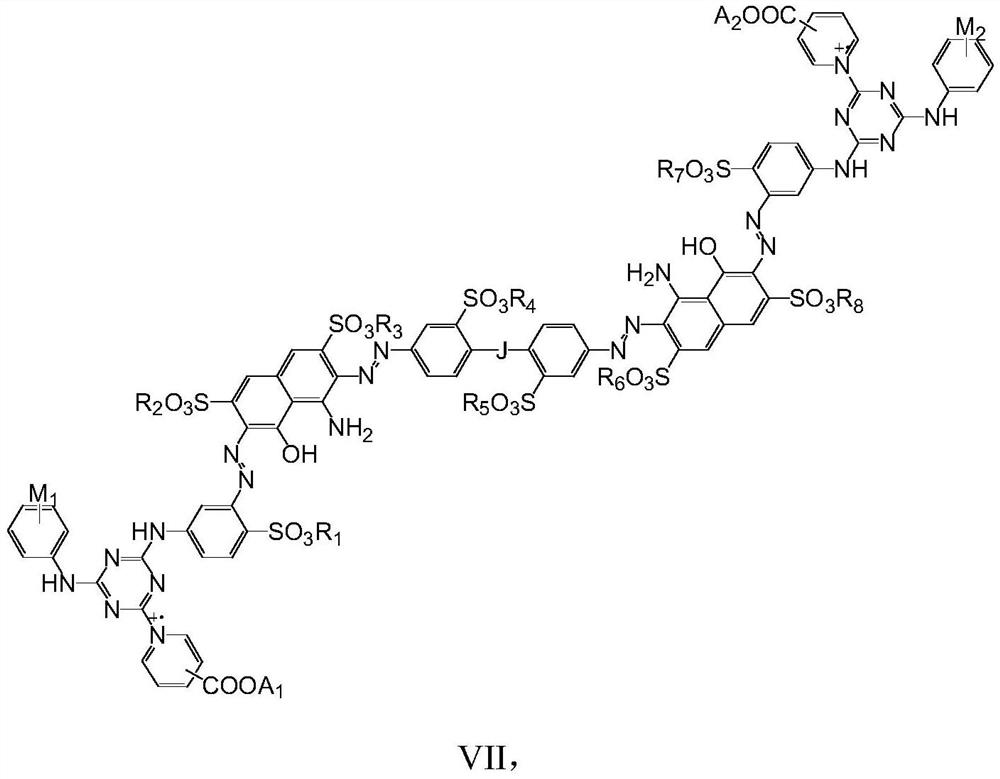

The structural formula of product is as follows:

[0078...

Embodiment 2

(5) hydrochloric acid and sodium nitrite are added in the 4th mixed solution that step (4) obtains, react 1.5 hours at 0-5 ℃

When obtaining the fifth mixed solution, wherein, the molar ratio of HCl and sodium nitrite is 1:2.0:1.0;

(6) the second mixed solution that step (2) obtains is added in the fifth mixed solution that step (5) obtains, adds hydrogen carbonate

Sodium adjusts the pH value to 6.0-6.5, and reacts at 10-15° C. for 4 hours to obtain a sixth mixed solution, wherein the second mixed solution and

The fifth mixed solution feeding is 1:1.03 according to the molar ratio of feeding;

(7) will add in the sixth mixed solution that step (6) obtains, add sodium carbonate and adjust pH value to 5.5~

6.0, react at 75~80 ℃ for 6 hours to obtain the seventh mixed solution, wherein, with the molar ratio of feeding

1:2.5;

(8) the seventh mixed solution obtained in step (7) is dried to obtain product reactive dye blue.

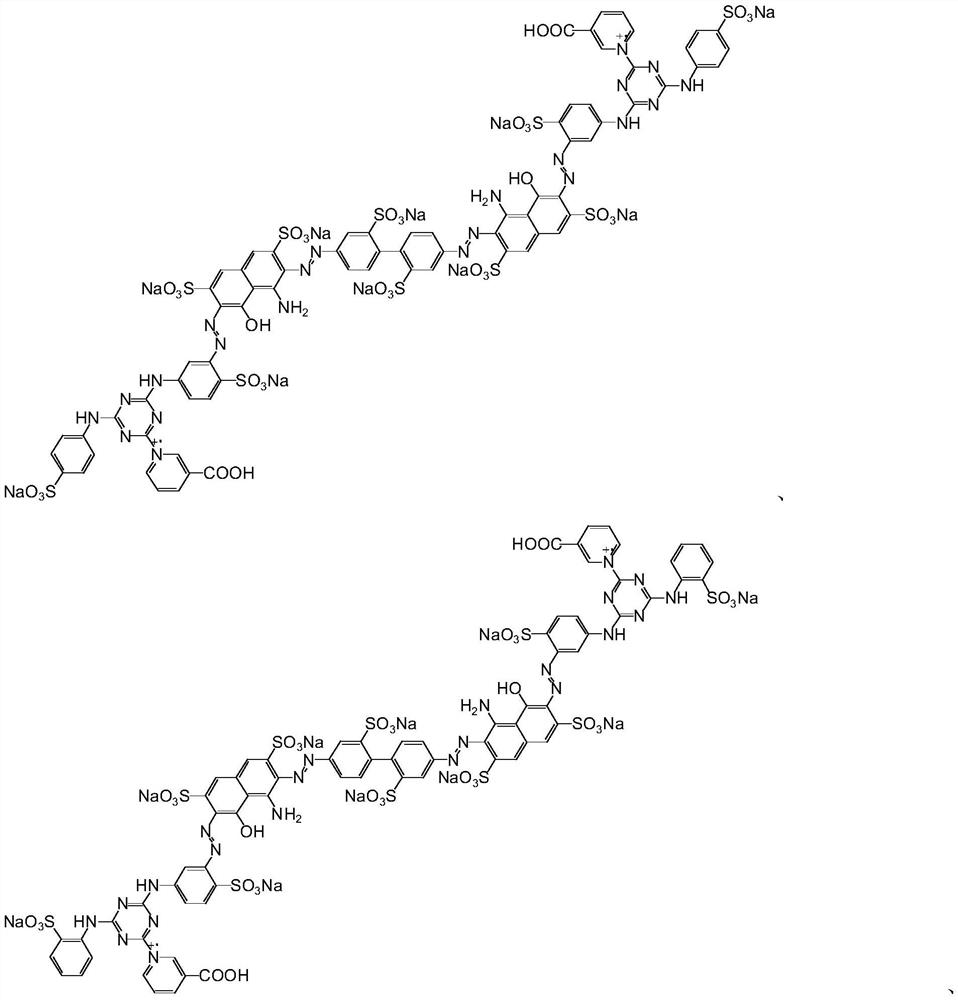

The structural formula of product is as follows:...

Embodiment 3

(5) hydrochloric acid and sodium nitrite are added in the 4th mixed solution that step (4) obtains, react 1.5 hours at 0-5 ℃

When obtaining the fifth mixed solution, wherein, the molar ratio of HCl and sodium nitrite is 1:2.0:1.0;

(6) the second mixed solution obtained by step (2) is added in the fifth mixed solution obtained by step (5), and hydrogen carbonate is added

Sodium adjusts the pH value to 6.0-6.5, and reacts at 10-15° C. for 3 hours to obtain a sixth mixed solution, wherein the second mixed solution and

The fifth mixed solution feeding is 1:1.03 according to the molar ratio of feeding;

(7) will add in the sixth mixed solution that step (6) obtains, add sodium carbonate and adjust pH value to 5.5~

6.0, react at 75~80 ℃ for 6 hours to obtain the seventh mixed solution, wherein, with the molar ratio of feeding

1:2.5;

(8) the seventh mixed solution obtained in step (7) is dried to obtain product reactive dye blue.

The structural formula of product is as fo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap