Combined partial circulation biomass gasification furnace and working method thereof

A biomass and combined technology, applied in the petroleum industry, the manufacture of combustible gas, etc., can solve the problems affecting the germination and rooting of new crops, restricting biomass gasification technology, and reducing the efficiency of biomass gasification, etc., to achieve simple biomass Step-by-step gasification to achieve drying and high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

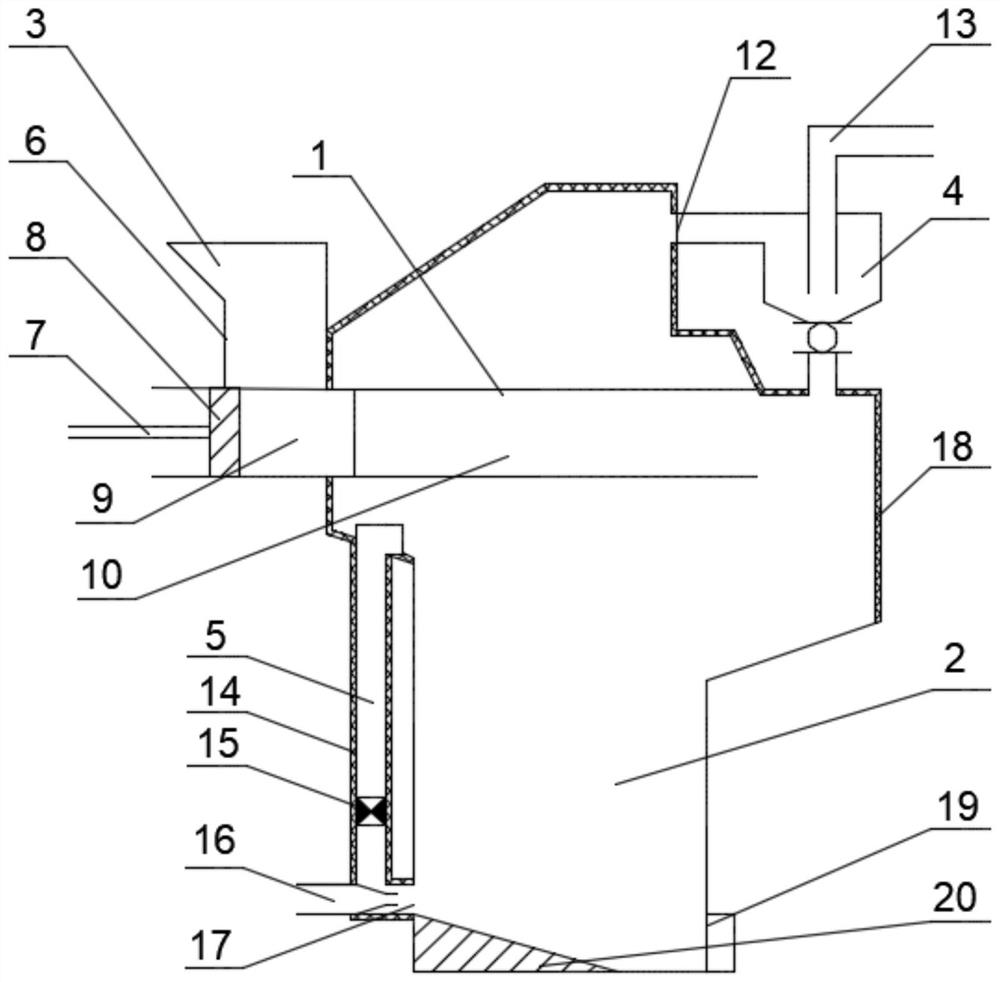

[0032] The present invention will be described in further detail below in conjunction with accompanying drawing, and its content is explanation of the present invention rather than limitation:

[0033] Such as figure 1 , is a combined partial circulation biomass gasifier of the present invention, including a horizontal furnace body 1, a vertical furnace body 2, a feeding system 3, a dust removal device 4 and a gasification gas circulation device 5.

[0034] The feeding system 3 includes a feeding hopper 6, a hydraulic feeding device 7 and a feeding plate 8, the feeding hopper 6 is arranged above the feeding section 9, and the hydraulic feeding device 7 and the feeding plate 8 are arranged in the feeding section 9 , The hydraulic feeding device 7 is connected with the feeding plate 8 .

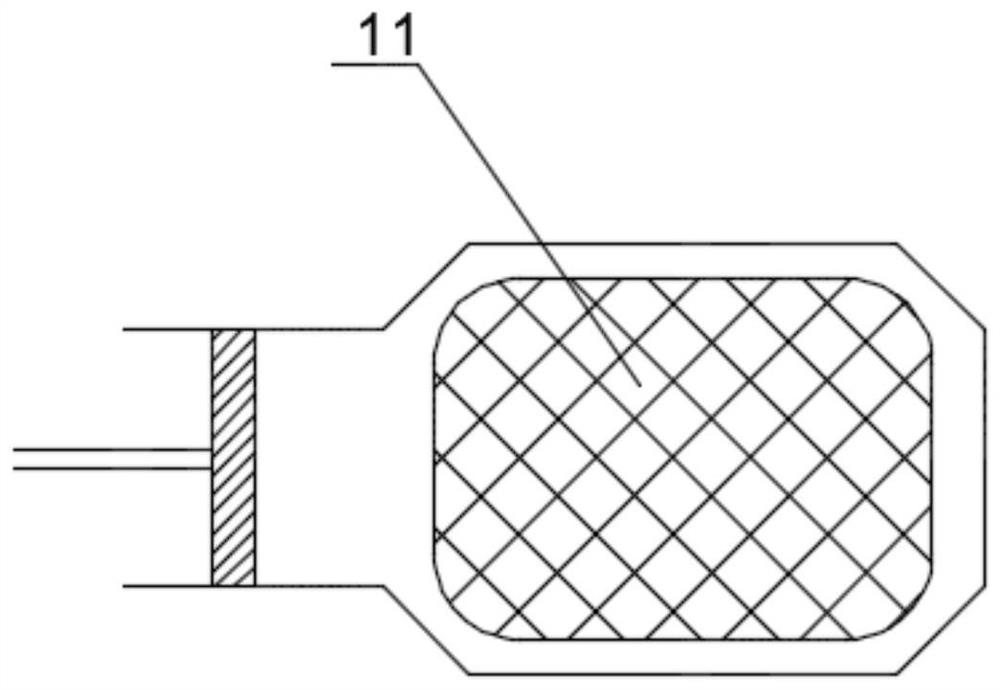

[0035] The horizontal furnace body 1 comprises a feeding section 9 and a drying-gasification section 10, the length of the feeding section 9 is 1 / 3 of the horizontal furnace body 1, and the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com