Rapid fabric padding equipment

A fast, padding technology, applied in the field of fabric processing, can solve the problems of the impregnating liquid cannot be circulated quickly, the concentration of the impregnating liquid is uneven, and it is not conducive to the full impregnation of the fabric, so as to increase the concentration uniformity, increase the grinding efficiency and reduce the tightness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

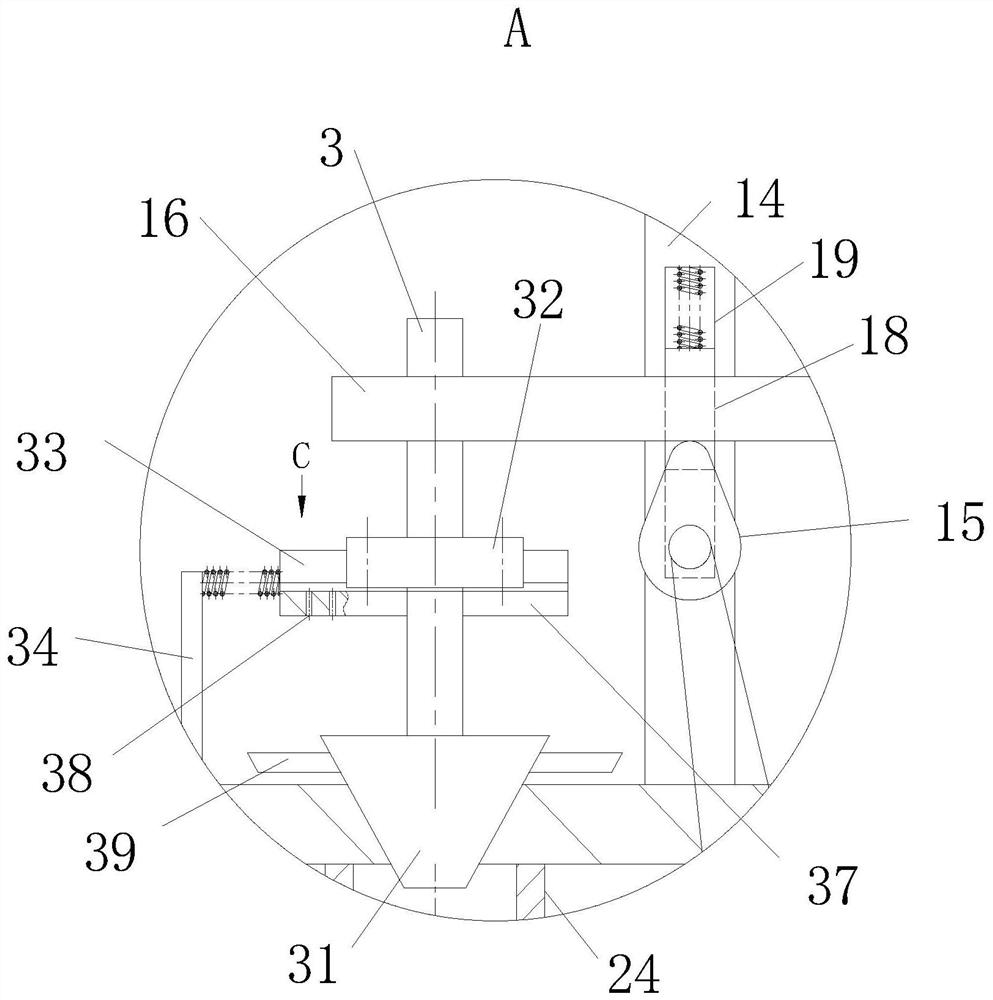

[0025]As an embodiment of the present invention, the bottom of the piston 21 is hinged with a pair of struts 26 through the connecting rod 25, and the end of the struts 26 away from the connecting rod 25 is hinged with a wedge-shaped clamping block 27; There is a group of springs fixedly connected between them; the bottom position of the box 1 is provided with a drain pipe 28 corresponding to the position of the No. 1 pipe 2, and a shut-off valve is provided on the drain pipe 28; The tapered part 29 that fits at the end; when the piston 21 drives the connecting rod 25 to move down together, the connecting rod 25 pushes the clamp block 27 to slide downward, and the bottom of the clamp block 27 contacts the tapered part 29 and then slides along the tapered part 29, Then the two clamping blocks 27 are tightened after being close to each other, so that the incompletely dissolved dyed particles contained in the high-concentration immersion liquid flowing out from the feeding box 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com