Safe enhanced ultrasonic roller

An ultrasonic and enhanced technology, which is applied in the field of safety-enhanced ultrasonic rollers, can solve the problems of ultrasonic vibrator falling off, affecting the vibrator, and damage to electrical performance, and achieves the effect of combining stability and reliability, ensuring cleaning effect, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments will be described in detail with reference to the accompanying drawings.

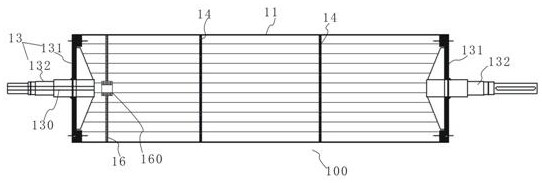

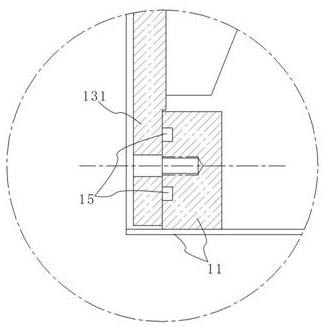

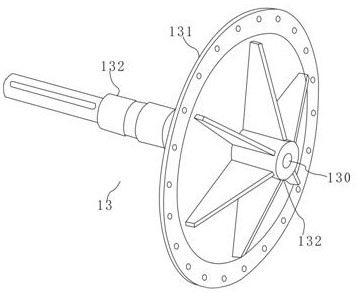

[0030] Such as Figure 1-6 As shown, this embodiment provides a safety-reinforced ultrasonic roller, including a cylinder 11, a plurality of rows of ultrasonic vibrators 12 annularly distributed on the inner wall of the cylinder 11, and a safety device located in the cylinder 11 and in contact with each ultrasonic vibrator 12 , the ultrasonic drum 100 is arranged inside the ultrasonic washing machine, and the cloth to be washed is spread and guided, and the plane is close to the ultrasonic drum 100 and travels backward with the rotation of the ultrasonic drum 100 .

[0031] In this embodiment, the cylinder 11 is a regular prism cylinder and its inner wall is a regular prism cavity wall, and the ultrasonic vibrators 12 are fixed on the regular prism cavity w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com