Novel mechanical oil pump driven by main reduction gear

A mechanical oil pump and gear-driven technology, which is applied in the field of mechanical oil pumps, can solve problems such as difficult active lubrication work, complex installation structure of the connection structure, etc., and achieve the effect of simple and reasonable connection structure, simple structure and simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

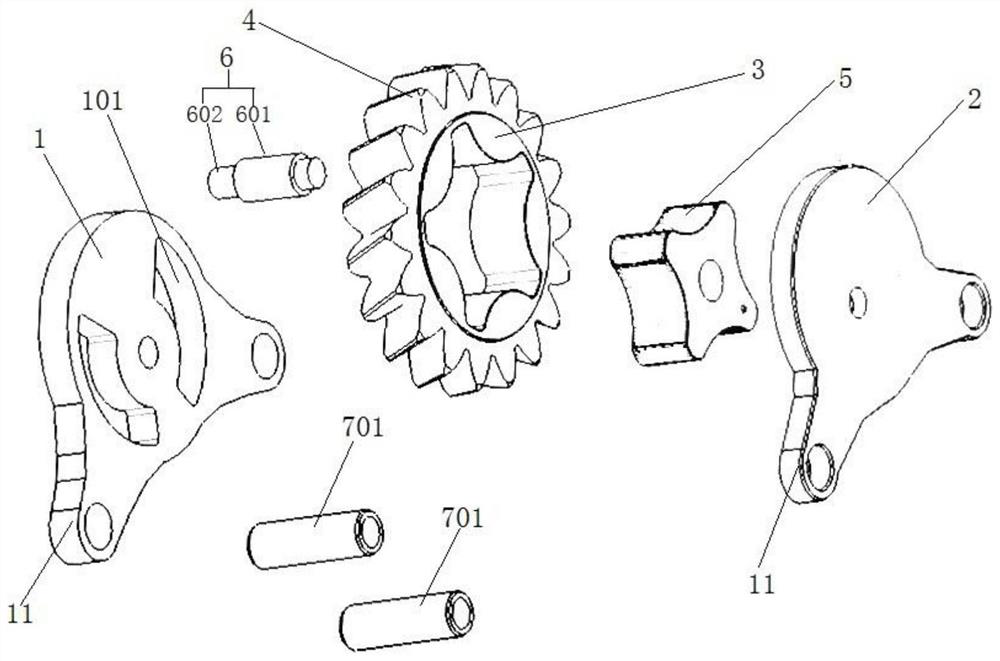

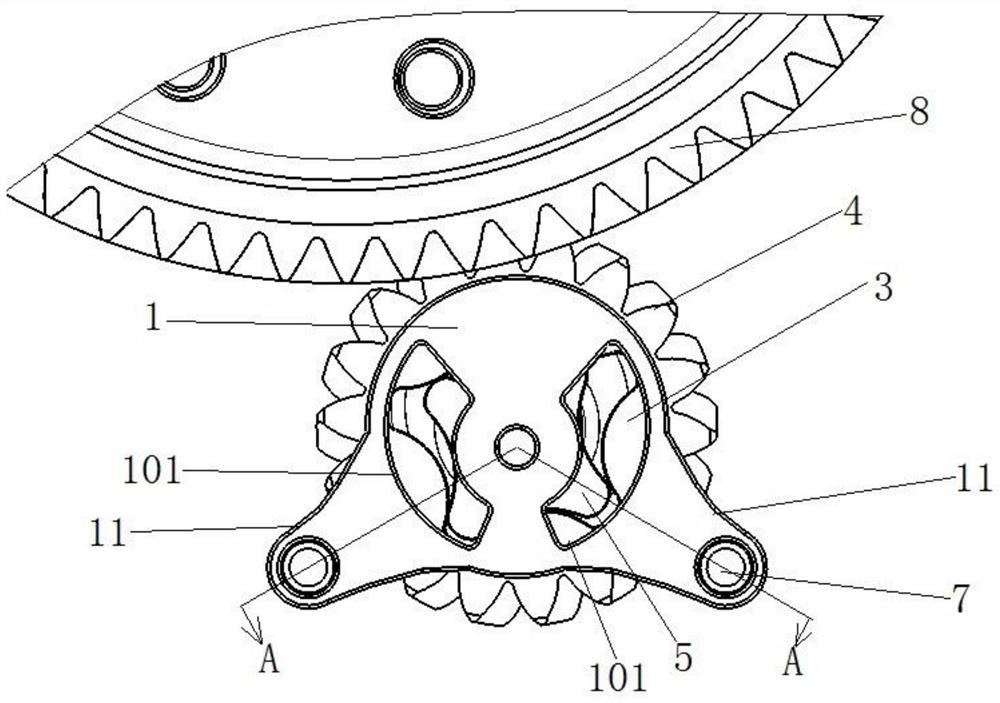

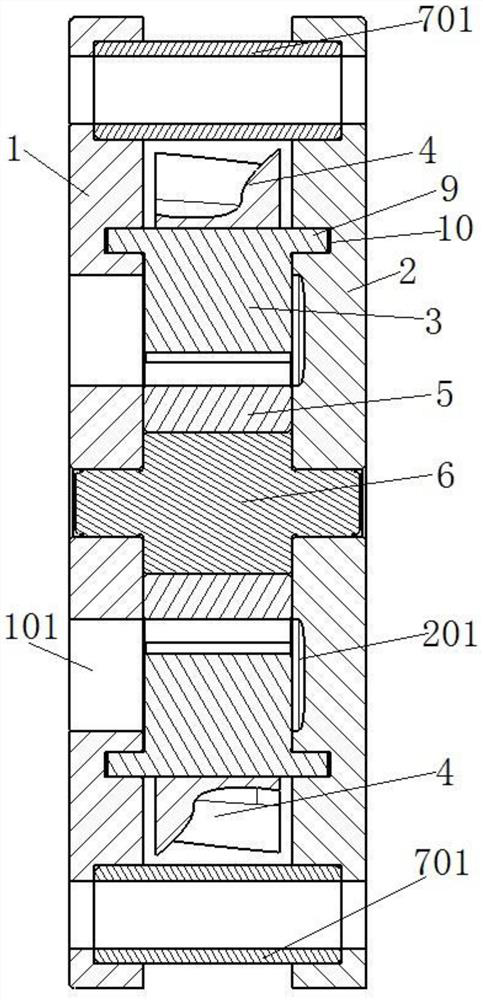

[0042] Such as Figure 1 to Figure 5 As shown, a new type of mechanical oil pump driven by the main reduction gear, the mechanical oil pump includes a first housing 1 and a second housing 2 that are mated and connected, and the first housing 1 and the second housing 2 is engaged with an outer rotor 3, the outer circumference of the outer rotor 3 is provided with an external tooth structure 4, and the outer diameter of the external tooth structure 4 is larger than that of the first housing 1 and the second housing 2, the outer tooth structure 4 is used to connect the main reduction gear 8; the inner circumference of the outer rotor 3 is equipped with an inner rotor 5, and the inner rotor 5 is connected to the The first housing 1 is connected to the second housing 2, the rotating pin 6 is coaxially arranged with the inner rotor 5, and the inner rotor 5 is eccentrically arranged with the outer rotor 6; the first The casing 1 and the second casing 2 are respectively provided with...

Embodiment 2

[0061] This embodiment provides the arrangement structure of the through holes on the first housing in the first embodiment.

[0062] Such as Figure 7 As shown, the through hole 101 and the counterbore 201 are two symmetrically arranged respectively, the through hole 101 and the counterbore 201 are fan-shaped holes, and a pair of adjacent radial sides of the fan-shaped holes The distance between them is smaller than the distance between the other adjacent radial sides, that is to say, the two fan-shaped holes are in a downwardly offset structure, which facilitates the pumping of the oil below.

[0063] Further, the arc radius of the short-side arc 14 of the fan-shaped hole is equal to the radius of the inner concave part of the inner rotor 5, that is, the radius at the minimum outer diameter 15 of the inner rotor; the long-side arc of the fan-shaped hole The arc diameter of 12 is equivalent to the radius of the concave part of the inner circumference of the outer rotor 3 , a...

Embodiment 3

[0065] The difference between this embodiment and the first embodiment lies in providing another structure of the first casing and the second casing.

[0066] Such as Figure 8 As shown, both the first housing 1 and the second housing 2 have three connecting lugs 11, the three connecting lugs 11 are arranged at intervals of 90 degrees, and the arrangement of the three connecting lugs 11 The stability of the connection and installation of the mechanical oil pump can be further improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com