A kind of coal slime drying and dehydrating device and drying and dehydrating method

A dehydration device and coal slime technology, applied in the direction of drying gas arrangement, drying chamber/container, drying solid materials, etc., can solve the problems that the surface of coal slime particles cannot be overheated and decomposed, coal slime particles are fully dried, etc., and achieve simple structure, High drying efficiency and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

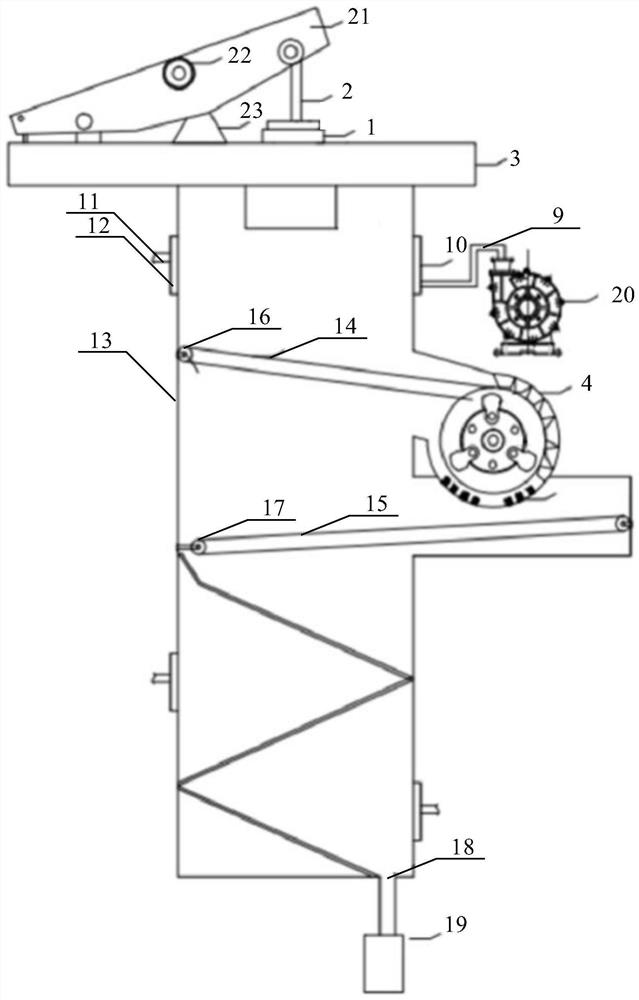

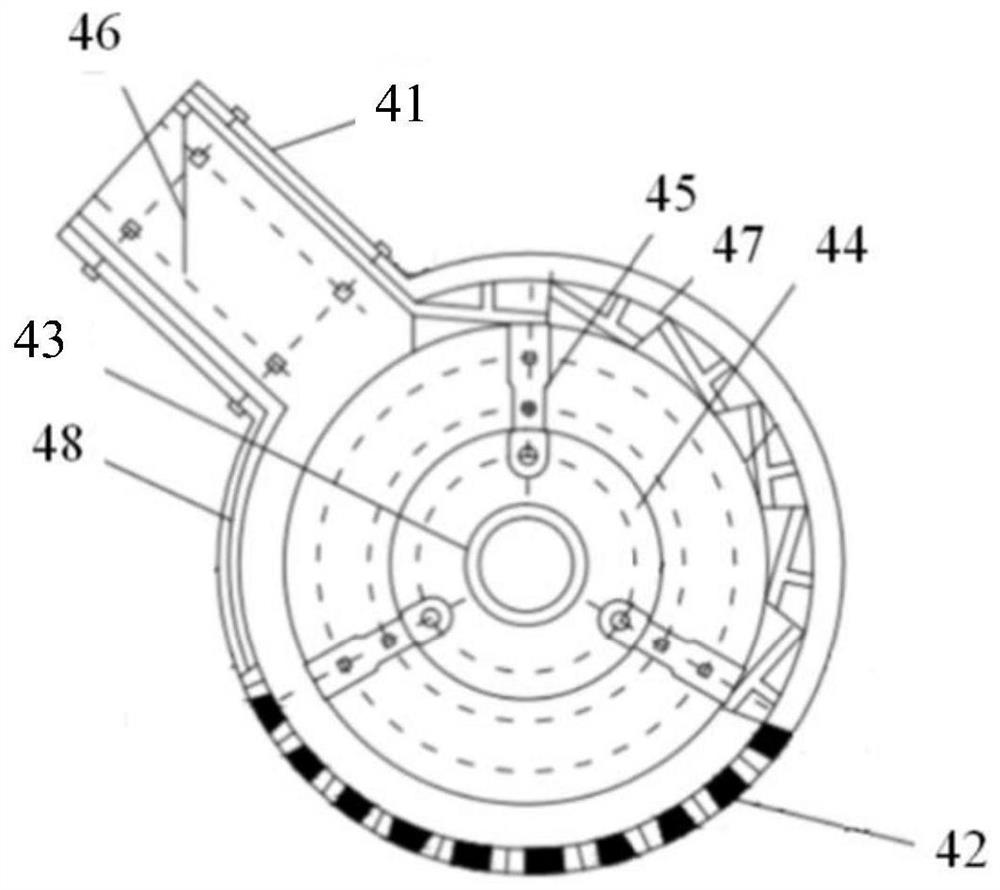

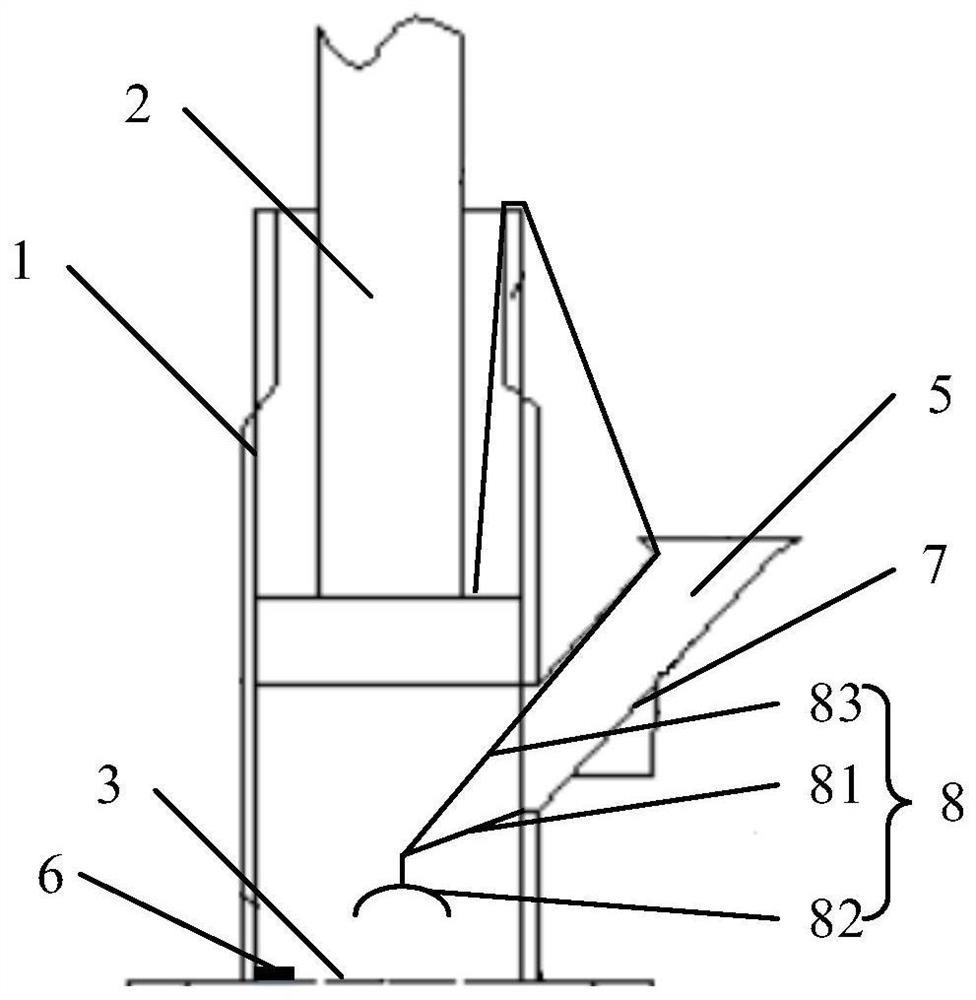

[0061] This embodiment provides a coal slime drying and dehydrating device, see Figure 1 to Figure 4 , including a strip making unit, a drying and crushing unit and a coal slime collection unit connected in sequence, wherein the coal slime drying and crushing unit includes a drying cylinder 13 and a primary drying mesh belt 14, a crusher and a secondary drying mesh arranged in the drying cylinder 13 Belt 15, drying gas is passed into the drying cylinder 13, the outlet of the strip making unit is located above one end of the primary drying mesh belt 14, the other end of the primary drying mesh belt 14 is connected with the feed port of the crusher, and the outlet of the crusher is The feed port is located above one end of the secondary drying mesh belt 15, and the other end of the secondary drying mesh belt 15 is connected with the coal slime collection unit.

[0062] It should be noted that the coal slime drying and crushing device provided in this embodiment is suitable for ...

Embodiment 2

[0088] This embodiment provides a method for drying and dehydrating coal slime, comprising the following steps:

[0089] Step 1: Transport the slime filter cake to the strip making unit for strip making to obtain slime strips;

[0090] Step 2: The slime strips are transported to the drying and crushing unit, and are dried once on the primary drying mesh belt 14;

[0091] Step 3: Transport the once-dried slime strips to a crusher, and the crusher crushes the slime strips to obtain slime particles;

[0092] Step 4: The coal slime particles are subjected to secondary drying on the secondary drying mesh belt 15 to complete the drying and dehydration of the coal slime.

[0093] Compared with the prior art, the beneficial effects of the coal slime drying and dehydrating method provided in this embodiment are basically the same as those of the coal slime drying and dehydrating device provided in Embodiment 1, and will not be repeated here.

[0094] The sliver making unit includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com