Peripheral side plate transfer working station apparatus

A technology of transfer workers and side panels, which is applied in the field of running vehicles, can solve problems such as easy shaking, affecting product quality, and scratches on the surface of the peripheral side panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

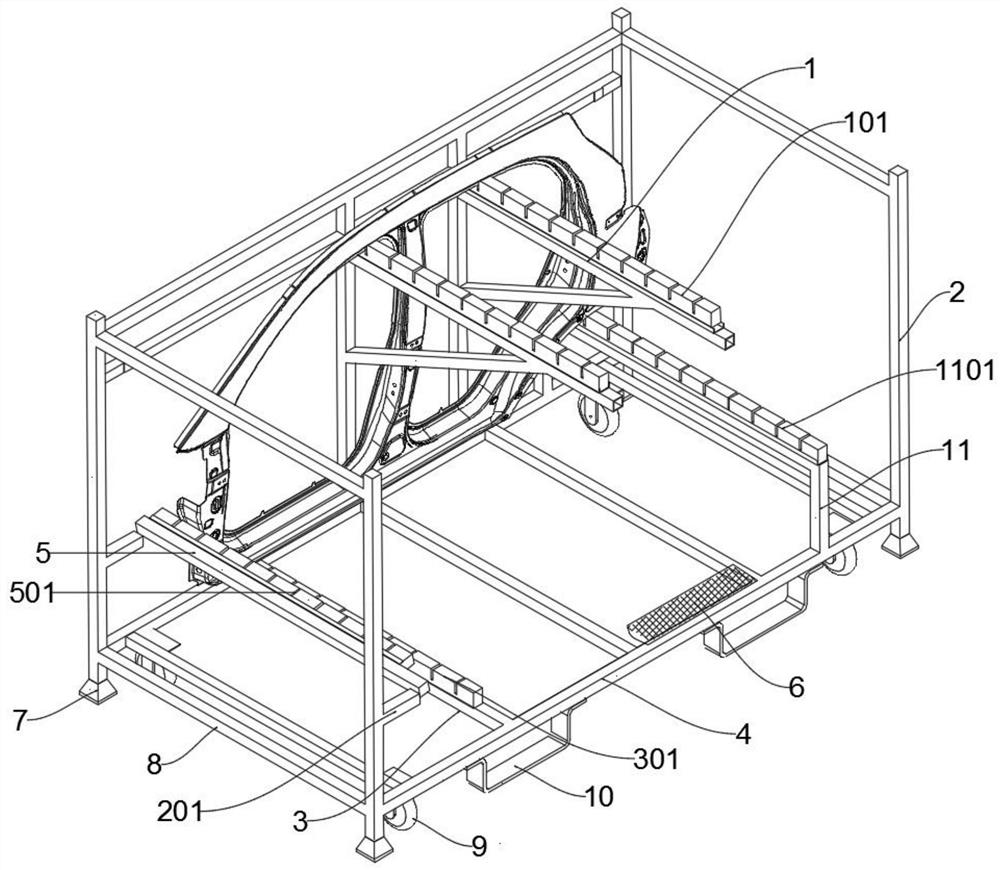

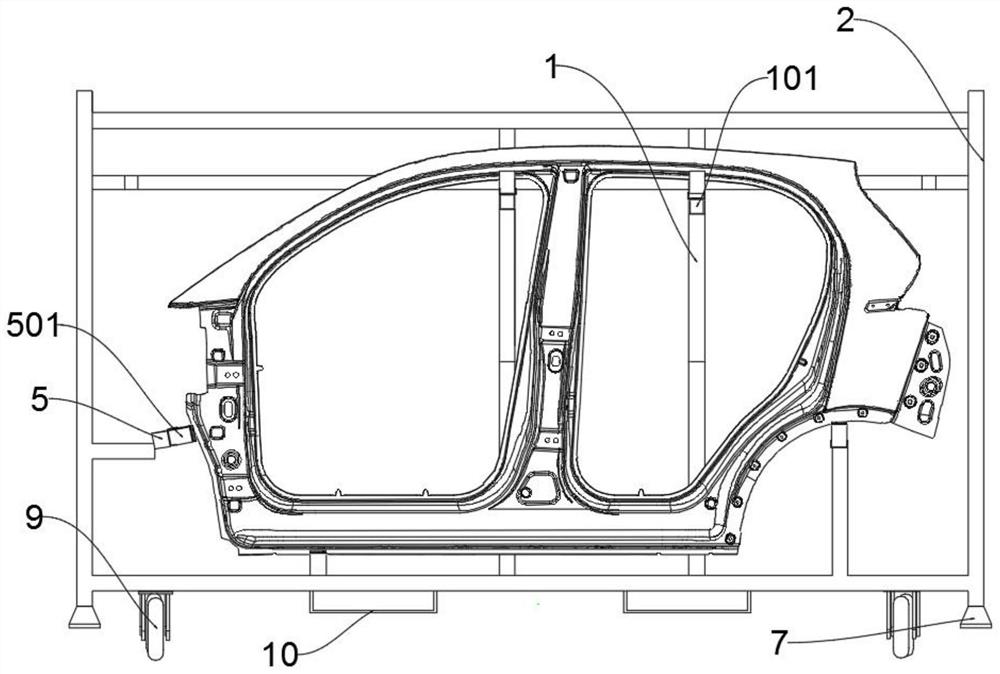

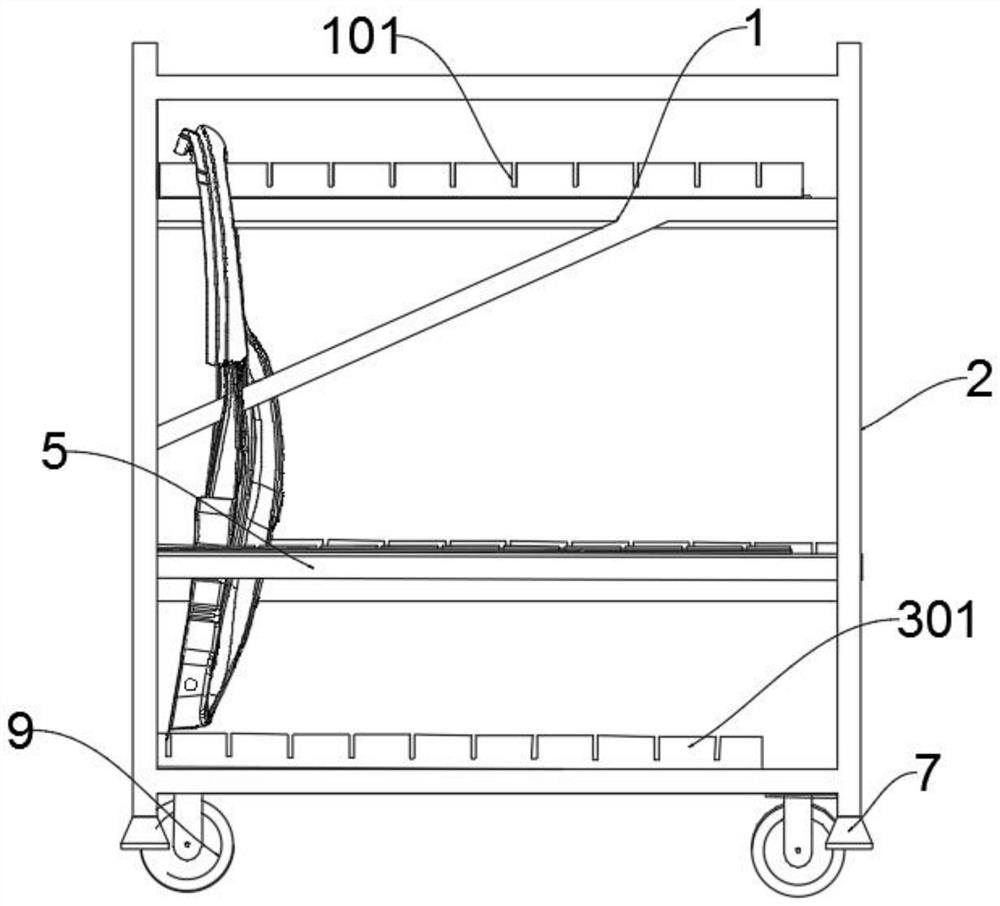

[0026] as attached figure 1 to attach Figure 4 Shown:

[0027] The present invention provides a peripheral side plate transfer station appliance, including an upper support frame 1, a column 2, a lower support frame 3, a front support frame 5, a steel mesh 6, a horseshoe seat 7, a longitudinal beam 8, wheels 9, and a forklift groove 10 , the rear support frame 11; the column 2 is connected to the beam 4 by welding; the rear upper end and the lower end of the upper support frame 1 are respectively connected to the two beams 4 above and below by welding, and the upper support frame 1 has two places; the lower support The two ends of the frame 3 are fixedly connected to the two two beams 4 below by welding; the front support frame 5 is connected to the end of the rail 201 of the column 2 by welding; the steel mesh 6 is fixedly connected to the inside of the frame of the beam 4; the horseshoe The seat 7 is connected to the lower end of the column 2 by welding; the longitudinal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com